Adhesive tape scrap edge collecting device

A collection device and tape technology, used in transportation and packaging, sending objects, thin material handling, etc., can solve the problems of reducing the effective working time of the machine, reducing the working efficiency of the machine, frequent replacement of nylon sleeves, etc., to increase the amount of waste collected. , the effect of improving utilization and reducing the number of downtimes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] To enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

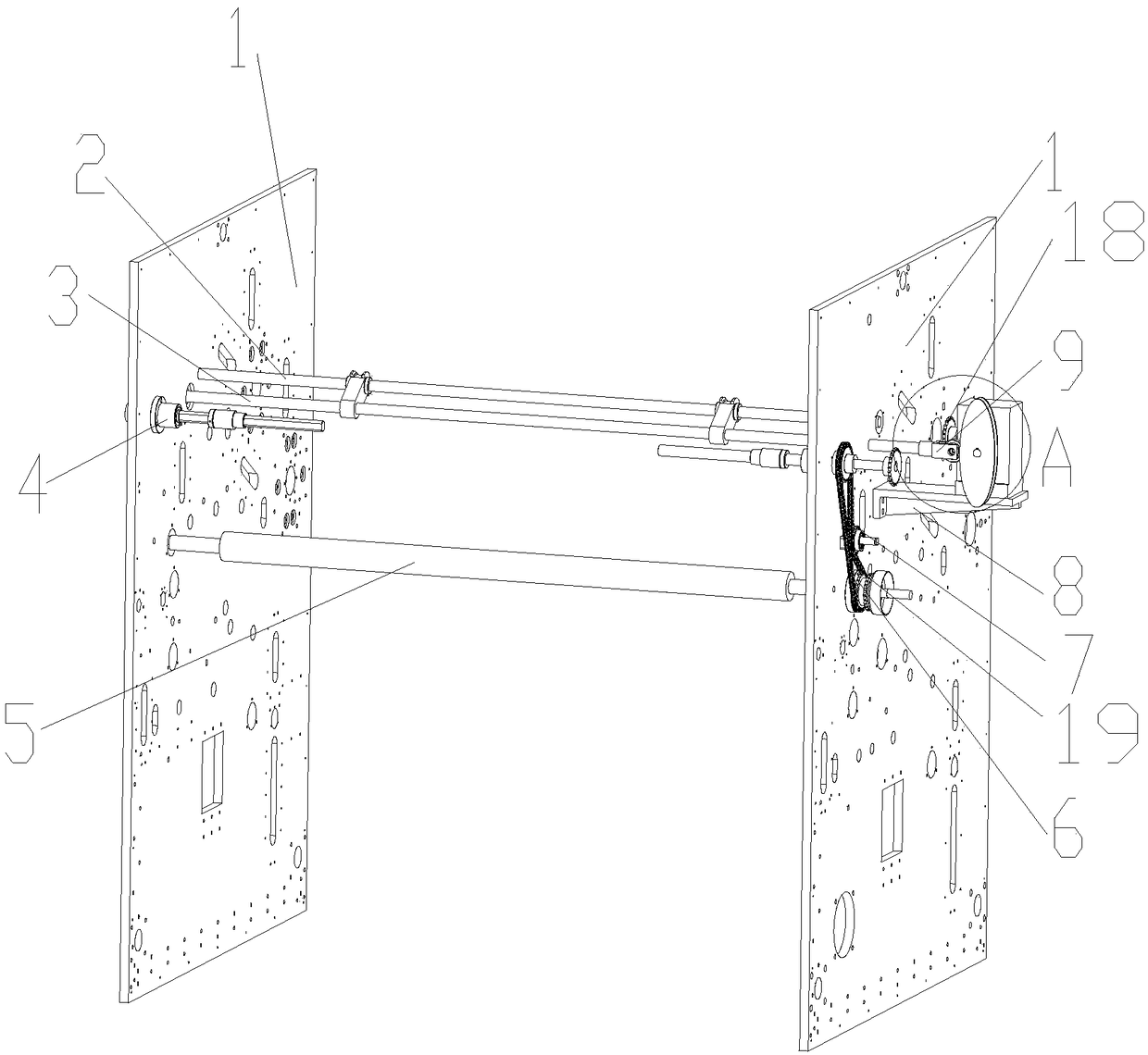

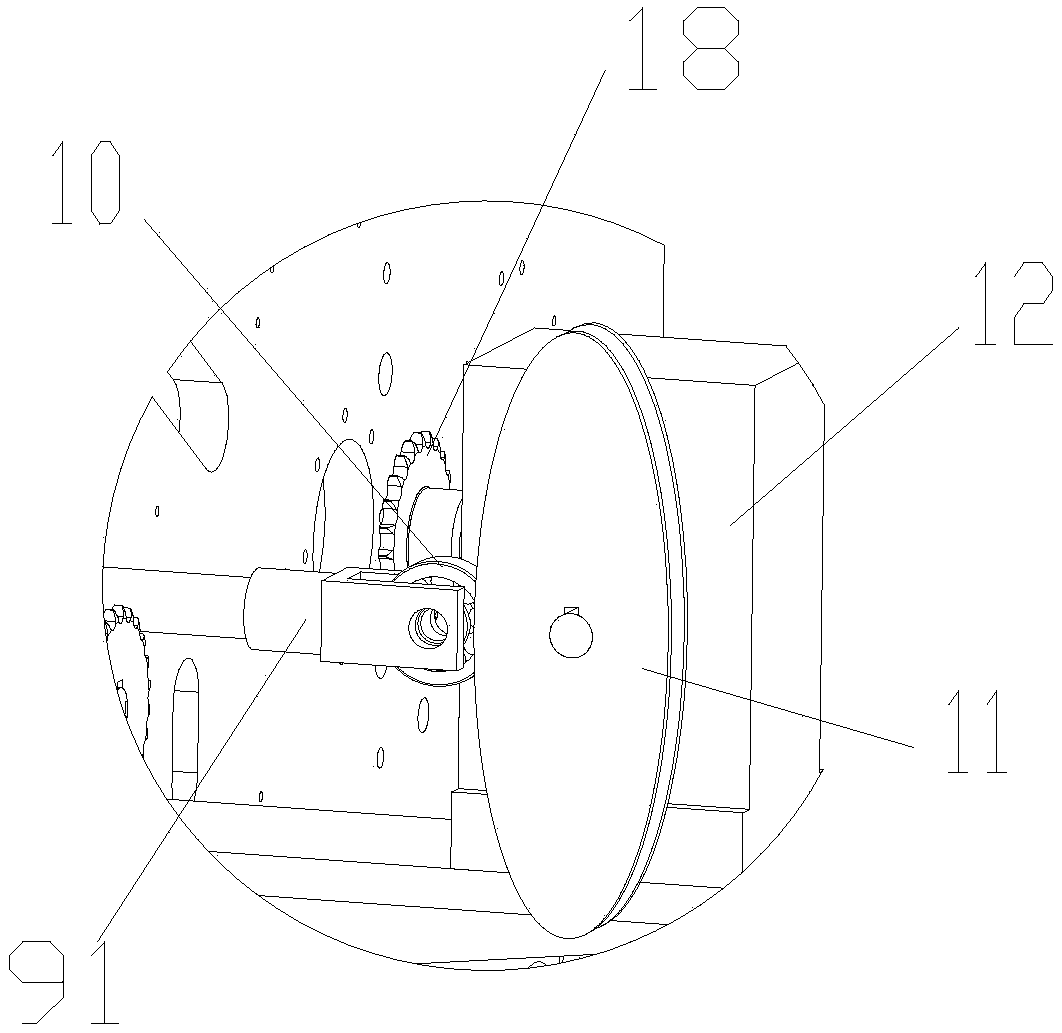

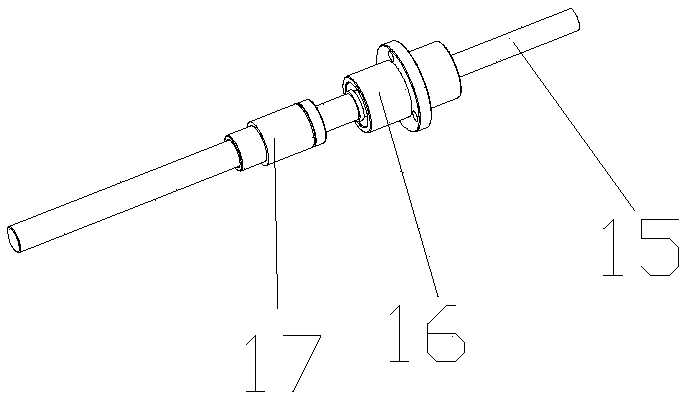

[0021] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention discloses a waste tape collection device for a tape slitting machine, including a wallboard 1, a guide shaft 2, a movement shaft 3, a ferrule 13, a waste collection shaft 15, a first The driving device and the second driving device, two wall boards 1 are parallel to each other, the guide shaft 2 is connected between the two wall boards 1 in rotation, the two ends of the moving shaft 3 pass through the two wall boards 1 respectively, and the moving shaft After one end of 3 passes through the corresponding wallboard 1, the axial movement is realized through the first driving device installed on the outside of the wallboard 1. The two ferrules 13 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com