Solid-wood bed processing equipment

A processing equipment, solid wood technology, applied in the field of bed processing, can solve problems such as excessive dust, air pollution, affecting the health of workers, and achieve the effect of reducing pollution, improving processing, and ensuring physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

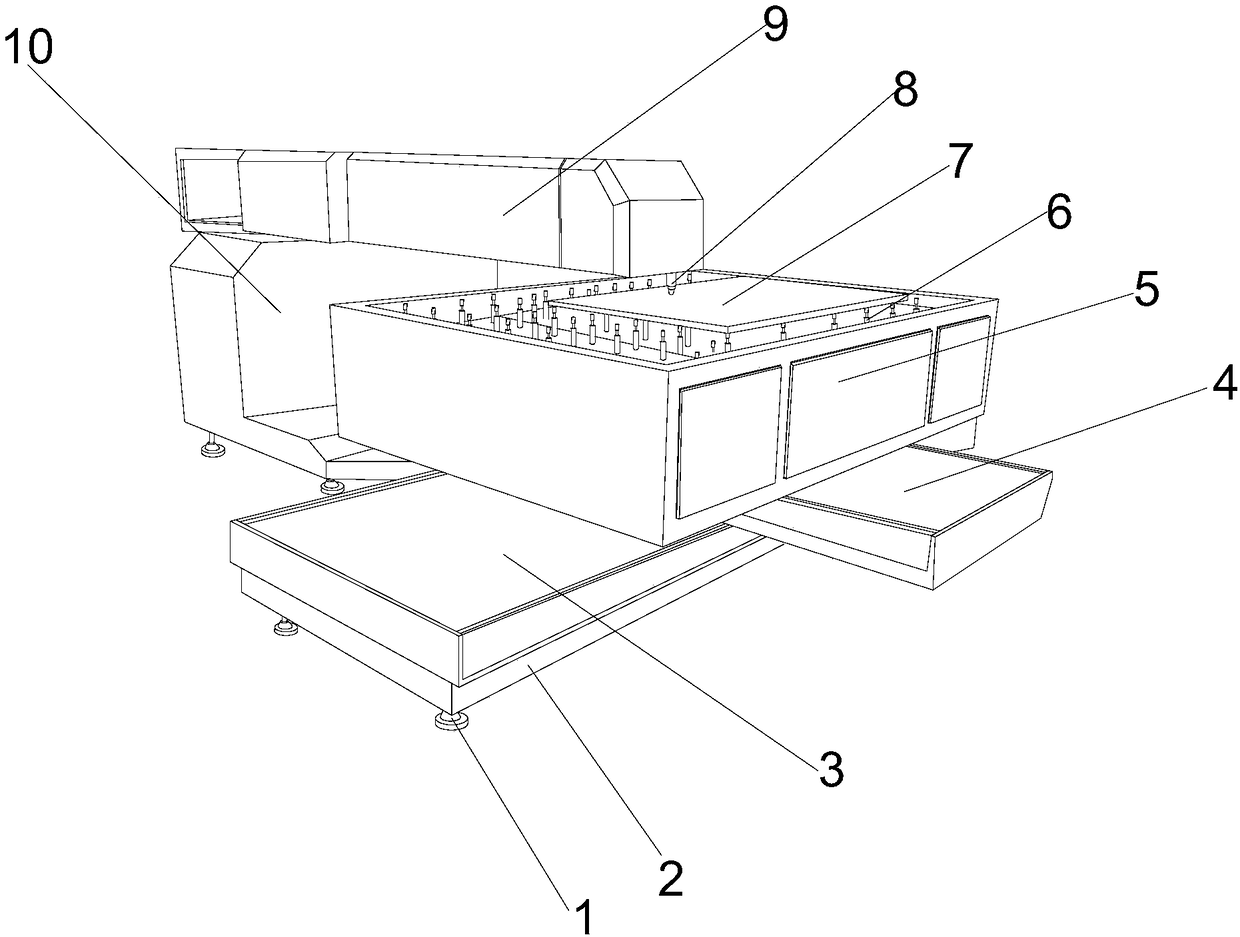

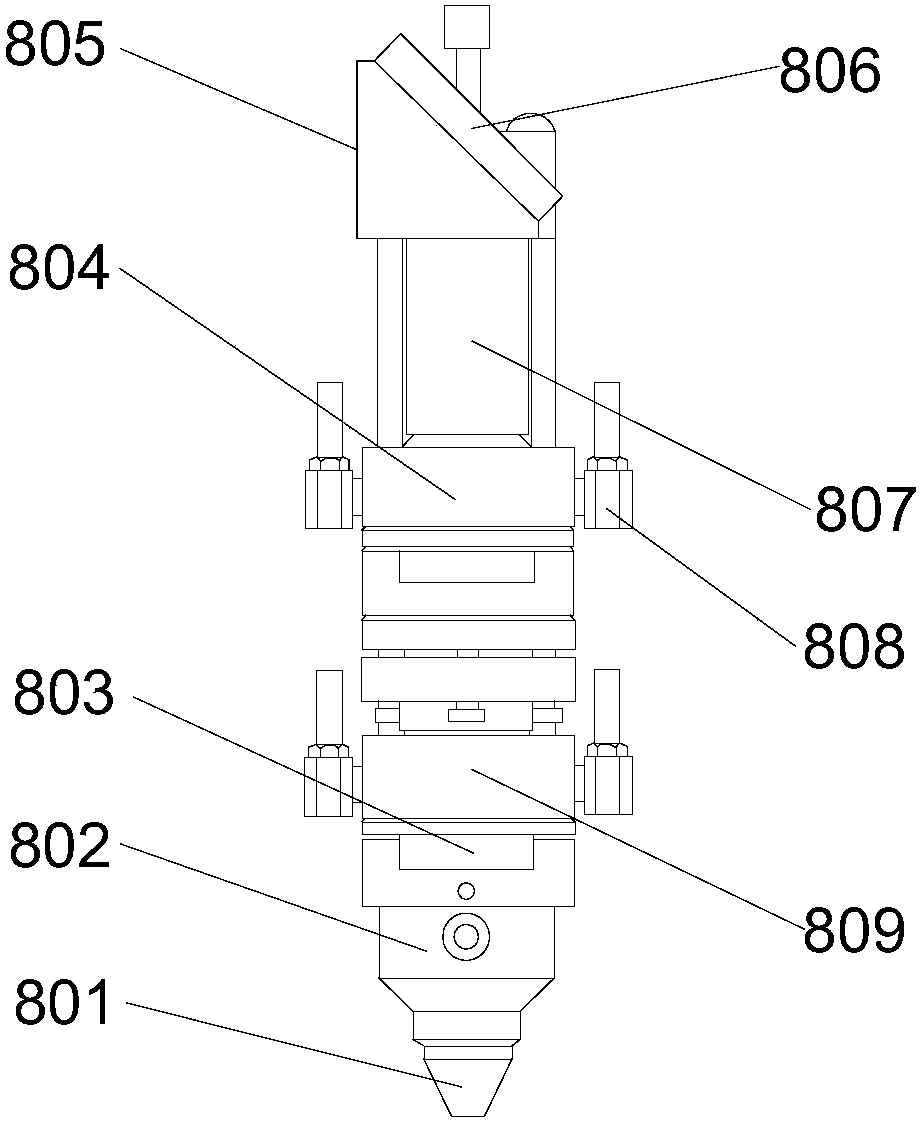

[0019] See figure 1 versus figure 2 , The present invention provides a technical solution for solid wood bed processing equipment: its structure includes a tripod 1, a base 2, a horizontally moving plate 3, a longitudinally moving plate 4, a working platform 5, a top rod 6, a solid wood bed plate 7, and a laser processing device 8. Support beam 9, support seat 10, said tripod 1 is vertically installed at the bottom of base 2, the upper surface of said base 2 is attached to the bottom of horizontally moving plate 3, and said vertical moving plate 4 is horizontally installed on the upper end of horizontally moving plate 3 , The upper surface of the longitudinal moving plate 4 is connected with the bottom of the working platform 5, the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com