Battery pack cooling and heating integral structure

A battery pack and topology technology, applied in the application field of new energy vehicles, can solve the problems of pipeline system equipment and manufacturing difficulties, large battery inertial load, leakage and other problems, and achieve the effect of low weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

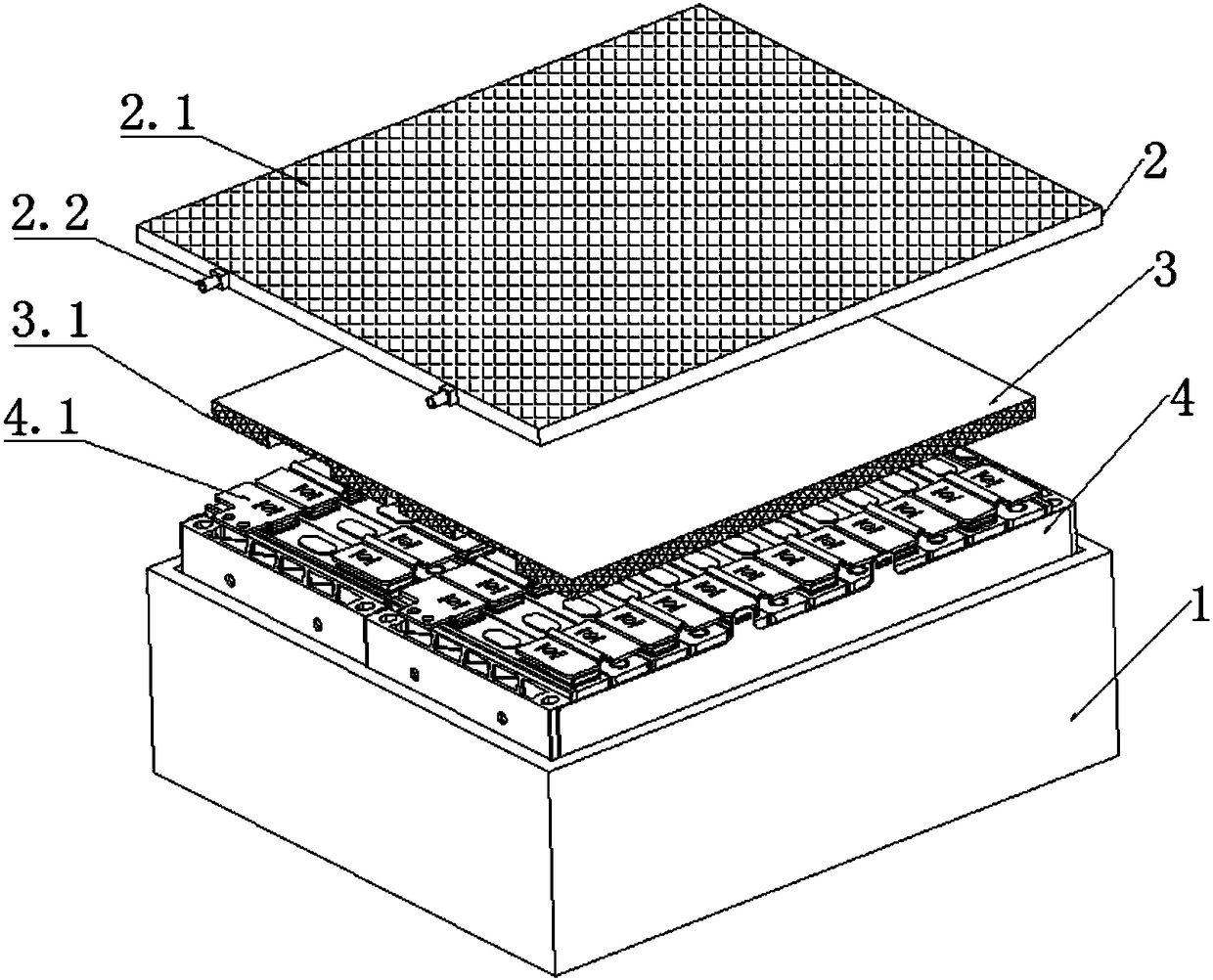

[0024] refer to figure 1 , an integrated structure for cooling and heating of the battery pack proposed by the present invention, including: a box body 1, a box cover 2, a heat transfer structure 3 and a module 4, and the heat transfer structure 3 is a heat conducting and insulating structure.

[0025] The module 4 is installed in the box body 1 so as to protect, support and fix the module 4 . The box cover 2 is covered on the box body 1 and connected with the box body 1 .

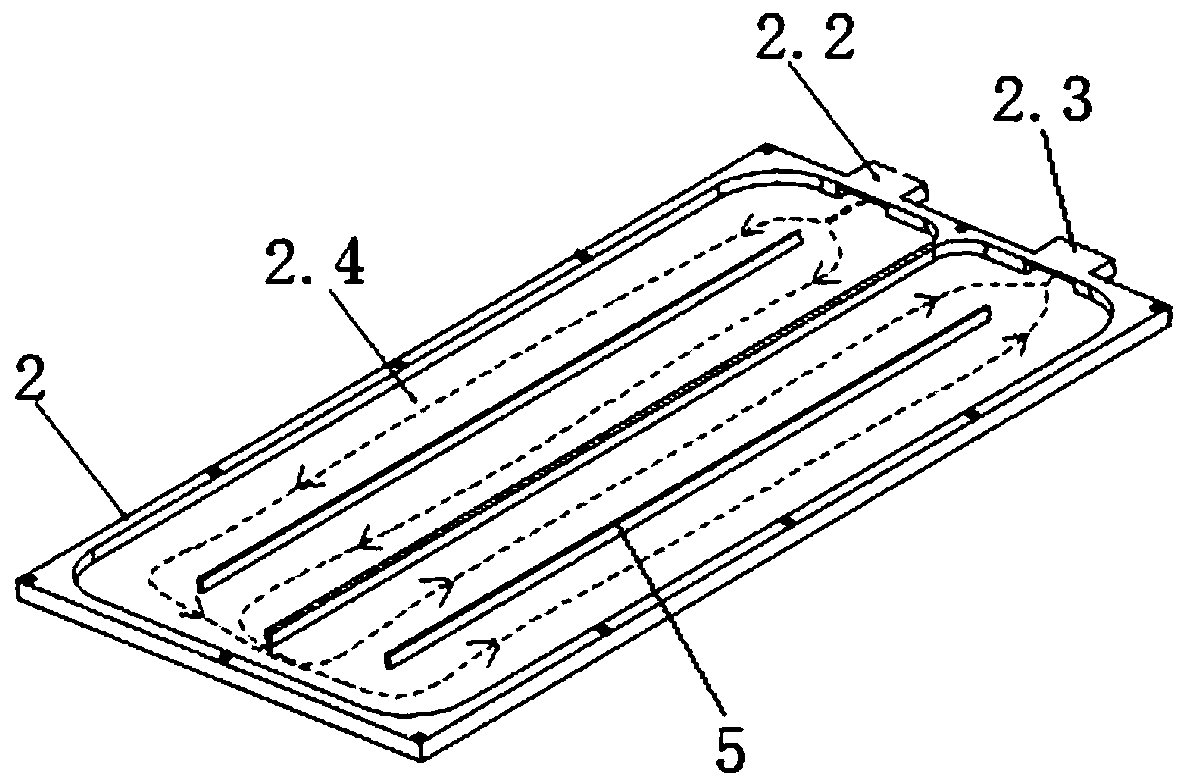

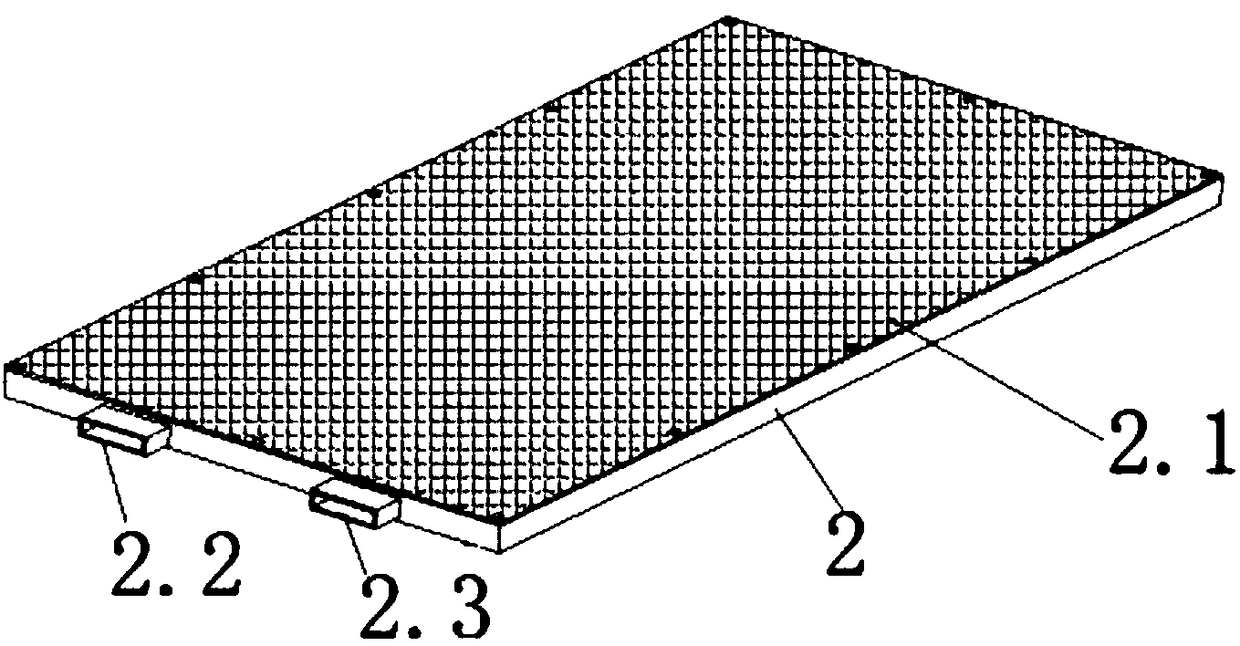

[0026] The inside of the box cover 2 is provided with a heat conduction cavity 2.4, and the heat transfer structure 3 covers the module 4 and adheres to the lower surface of the box cover 2. The side of the case cover 2 is provided with an input joint 2.2 and an output joint 2.3 communicating with the heat conduction cavity, and the input joint 2.2, the heat conduction cavity and the output joint 2.3 are sequentially connected to form a fluid delivery path. In this way, a sealed environment is formed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com