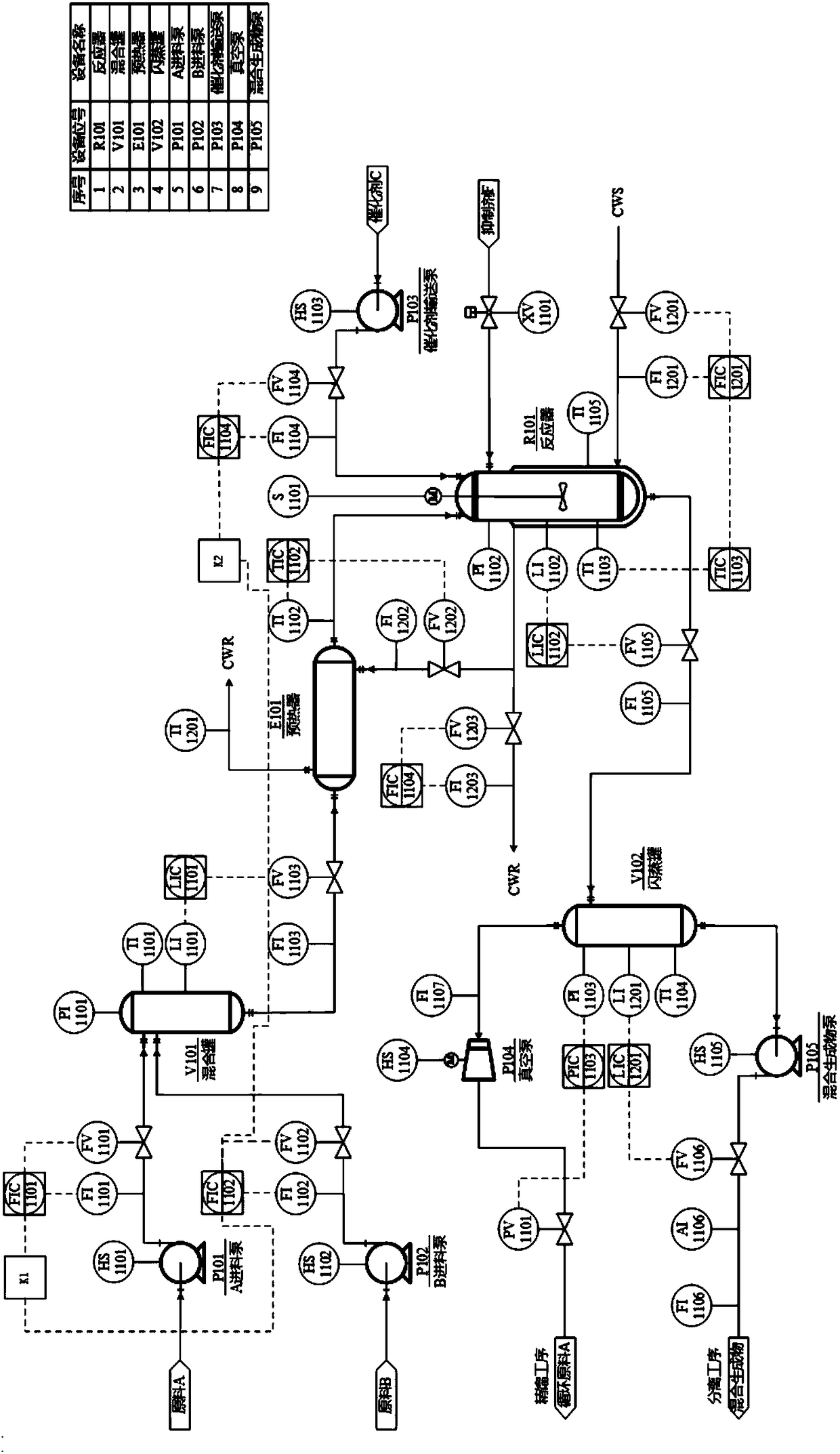

PCS7-based polymerization reactor control device and control method thereof

A polymerization reactor and control device technology, applied in the field of control, can solve problems such as large energy consumption, unstable system operation, and low utilization rate of raw materials, etc., and achieve the effect of powerful functional design, humanized functional design, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

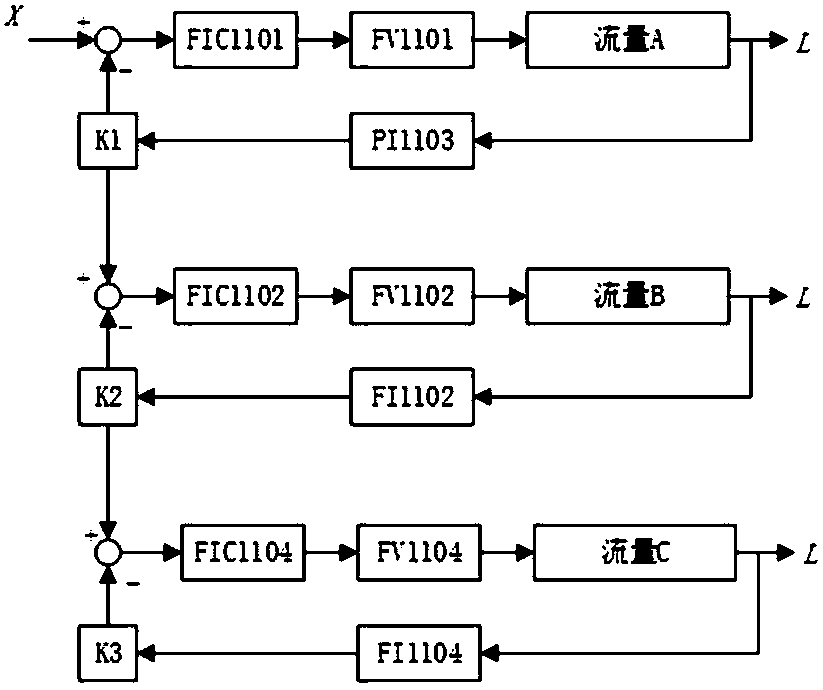

Method used

Image

Examples

Embodiment Construction

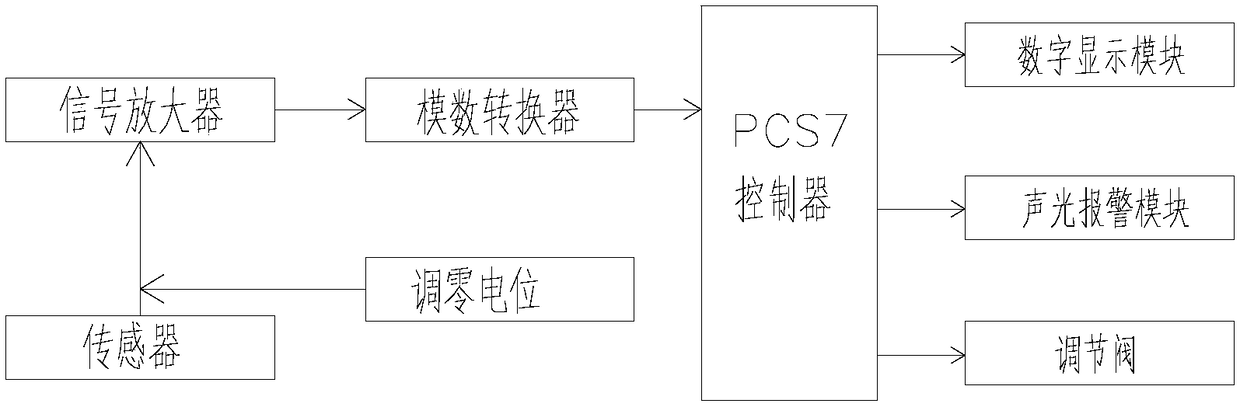

[0038] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 2 As shown, a polymerization reactor control device based on PCS7 includes a PCS7 controller, a digital display module, an audible and visual alarm module, an analog-to-digital converter, a signal amplifier, and several sensors and regulating valves; the sensor includes a liquid level sensor and a temperature sensor, connected with the PCS7 controller through the signal amplifier and the analog-to-digital converter, for monitoring the liquid level and temperature signals inside the reactor, and sending the liquid level and temperature signals to the PCS7 controller; The PCS7 controller is used to control the opening and closing of each regulating valve; the digital display module is connected with the PCS7 controller for displaying each regulating valve and the reactor operating conditions;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com