An Experimental Method for Obtaining Fatigue Small Cracks in Sheet Metal Parts Using Cellulose Acetate Film Replicas

A technology of cellulose acetate and experimental methods, which is applied in the field of obtaining small fatigue cracks in metal plates, can solve problems such as film ruptures, achieve the effects of reducing film ruptures, improving the success rate of replicas, and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] see Figure 1 to Figure 4 , an experimental method for obtaining small fatigue cracks in sheet metal parts using cellulose acetate film replicas, the steps of which are as follows:

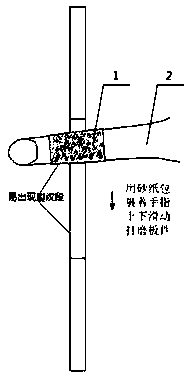

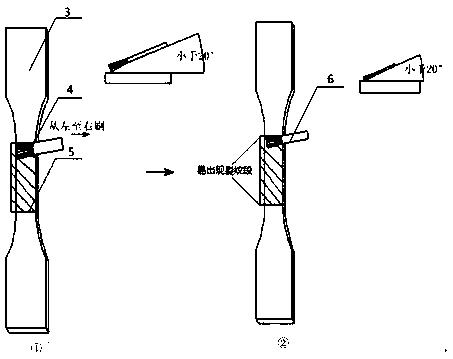

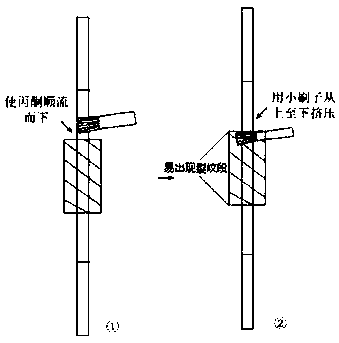

[0019] A) Provide a device for preparing a replica of a small fatigue crack in a metal plate, said device for preparing a replica of a small fatigue crack in a metal plate includes a grinding and polishing device, a fatigue testing machine, a cellulose acetate film, a hair brush, acetone and a metal plate , the grinding and polishing device includes a polishing machine, sandpaper and diamond grinding paste. B) Before the load is applied to the plate, first use sandpaper to polish the crack-prone section of the metal plate. When grinding the side of the metal plate with a thickness less than 10mm, use your fingers to wrap the sandpaper for grinding to avoid excessive grinding of the four sides of the metal plate. sharp, causing the film to tear during replicating, figure 1 ; Finally, polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com