Novel energy-saving gas burner

A gas burner, a new type of technology, applied in heating fuel, gaseous heating fuel, household heating, etc., can solve problems such as floating fire, excessive carbon emissions, and insufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

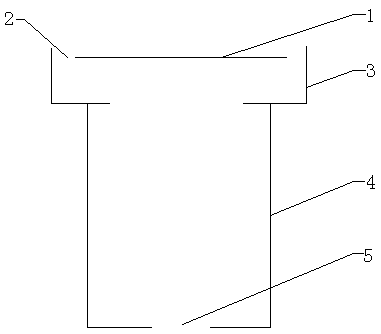

[0006] The gas burner has a round pipe gas supply pipe 4 with uniform up and down. The lower part of the gas supply pipe 4 is the air inlet 5. The upper end of the gas supply pipe 4 is placed with three flamethrowers 3 whose diameters are tangent. The flamethrower top plate 1 is located on the flamethrower 3. A groove 2 is left between the flamethrower 3 and the top plate 1 of the flamethrower, and the groove 2 communicates with the air inlet 5 up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com