LED-UV piezoelectric type spray printing ink with high adhesion and preparation method thereof

A high-adhesion, piezoelectric technology, used in inks, household appliances, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

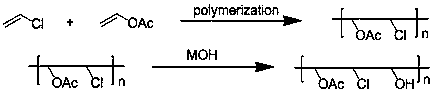

Method used

Image

Examples

preparation example Construction

[0312] 1. Preparation of pigment paste:

[0313] See Table 1 and 2 for the composition of sub-micron size yellow Yellow, magenta Magenta, cyan Cyan, and black black colorants.

[0314] Table 1 Composition of sub-micron size Yellow, Magenta, and Cyan pigment pastes

[0315]

[0316] Table 2 Composition of sub-micron size Black pigment paste

[0317]

[0318] Make color pastes of different colors according to the following production steps. Color paste production steps are as follows:

[0319] 1) Mix the pigment, polymerization inhibitor, reactive monomer solvent, and dispersant according to the formula in Table 1 and 2 to form a slurry, mix, and perform the pre-dispersion and wetting step for more than 8 hours;

[0320] 2) Put the slurry prepared in step 1) into a NETZSCH 10L grinder for high-speed grinding and dispersion. The grinding characteristics are: 300kg feeding amount, and the energy consumption per hour during grinding: 5±0.5kW. Color paste with micron parti...

preparation example 1

[0361] 1. Use a high-speed paint shaker to make color paste:

[0362] The pigments used are as follows: Magenta: C.I. Pigment Red 122; Blue: C.I.Pigment Blue 15:4; Yellow: C.I. Pigment Yellow 150; Black: C.I.Pigment Black 7; For white use toner: C.I. Pigment White 6.

[0363] The dispersant used is BYK9151; the polymerization inhibitor used is 4-methoxyphenol; the acrylic acid reactive monomer solvent or oligomer used is isobornyl acrylate.

[0364] Among them, the composition of sub-micron size yellow Yellow, magenta Magenta, cyan Cyan, and black Black color paste is shown in Table 4.

[0365] Table 4 Composition of sub-micron size Yellow, Magenta, Cyan, Black pigment-based colorants

[0366]

[0367] Operate the high-speed shaker under the following conditions:

[0368] Experimental conditions:

[0369] l High-speed vibration machine model: LAU Disperser DAS 200

[0370] l Choice of Zirconia beads: Zirconia beads (0.3-0.5mm)

[0371] l Filling rate of zirconium bead...

Embodiment 1

[0387] Ø Example 1: Same as Preparation Example 1, add VINNOL when making ink E15 / 40 A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com