Array-type combined electrode used for dense group hole electrosparking and preparation method thereof

A combined electrode and array technology, applied in electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of difficulty in guaranteeing the quality and efficiency of electrical processing, low efficiency, and high cost, shortening production preparation time and achieving high efficiency. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The array-type combined electrode for densely clustered hole electric discharge machining of the present invention will be further described below in conjunction with the embodiments of the specific description and accompanying drawings, but the protection content of the present invention is not limited to the following embodiments.

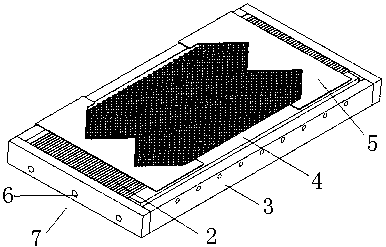

[0030] Such as Figure 1~5 Shown: the array type combination electrode and preparation method thereof of the present invention are as follows:

[0031] Design and manufacture the standard single electrode 1 and the array electrode mold 2 respectively; assemble the array electrode mold 2 in a row on the electrode base 3, and arrange a group of standard single electrodes 1 precisely for every two array electrode molds 2 side by side After the arrangement is completed, install the mold platen 4 in the electrode base 3, fasten it with screws, and press the array electrode mold 2 tightly; install the combined baffle plate 5 on the electrode bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com