Water aided injection forming device

An injection molding and water-assisted technology, which is applied in the field of plastic molding equipment, can solve problems such as unreasonable setting of action flow, unfavorable performance of molded parts, and inaccurate pressure control, etc., to achieve reasonable equipment combination, simple structure, and reduced failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

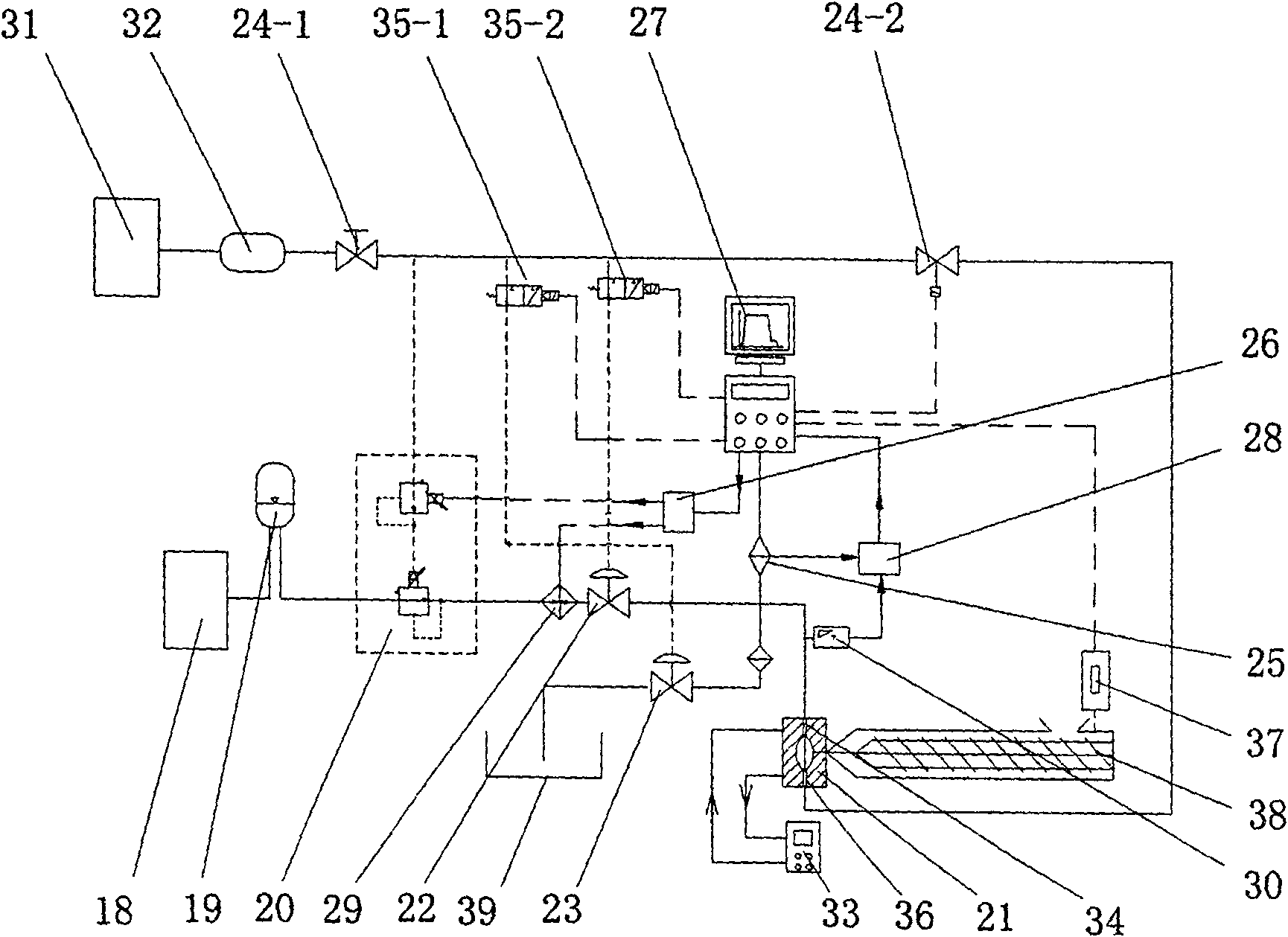

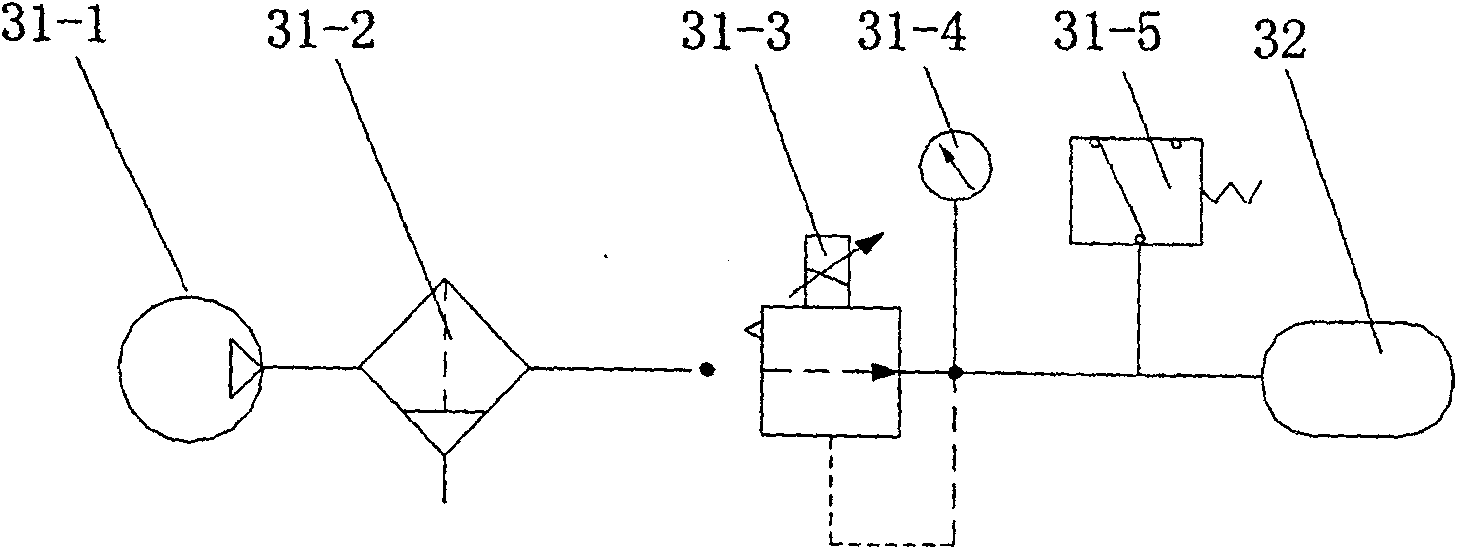

[0022] Figure 2 ~ Figure 3 A specific embodiment of the present invention is shown, by figure 2 It can be seen that the water-assisted injection molding equipment includes a small-flow water pump 18, a large-capacity accumulator 19, a proportional pressure reducing valve 20, a mold 21, a water injection shut-off valve 22, a drain shut-off valve 23, and drain air passage shut-off valves 24-1 and 24 -2, pressure sensor 25, digital / analog converter 26, computer 27, analog / digital converter 28, heater 29, temperature sensor 30, low-pressure gas forming device 31, low-pressure gas storage 32, mold temperature machine 33; The small flow water pump 18 is connected with the large-capacity accumulator 19, and the large-capacity accumulator 19 is connected with the proportional pressure reducing valve 20, and the proportional pressure reducing valve 20 is connected with the mold 21 through the heater 29 and the water injection stop valve 22. Connect; the proportional decompression va...

Embodiment 2

[0026] Figure 4 Shows another specific embodiment of the present invention, by Figure 4 It can be seen that the water-assisted injection molding equipment includes a small-flow water pump 18, a large-capacity accumulator 19, a proportional pressure reducing valve 39, a mold 21, a water injection shut-off valve 40, a drain shut-off valve 41, a pressure sensor 25, and a digital / analog converter 26 , computer 27, analog / digital converter 28, heater 29, temperature sensor 30, oil pump 42, overflow valve 43, mold temperature controller 33, air compressor 44, gas overflow valve 45, low-pressure gas storage system 46, gas Stop valve 47; the small flow water pump 18 is connected with the large-capacity accumulator 19, and the large-capacity accumulator 19 is connected with the proportional decompression valve 39, and the proportional decompression valve 39 passes through the heater 29 and the water injection shut-off valve 22 is connected with the mold 21; the proportional decompre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com