Centrifugal pump, in particular circulation pump

A technology of centrifugal pumps and circulating pumps, which is applied in the field of circulating pumps and can solve problems such as degradation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

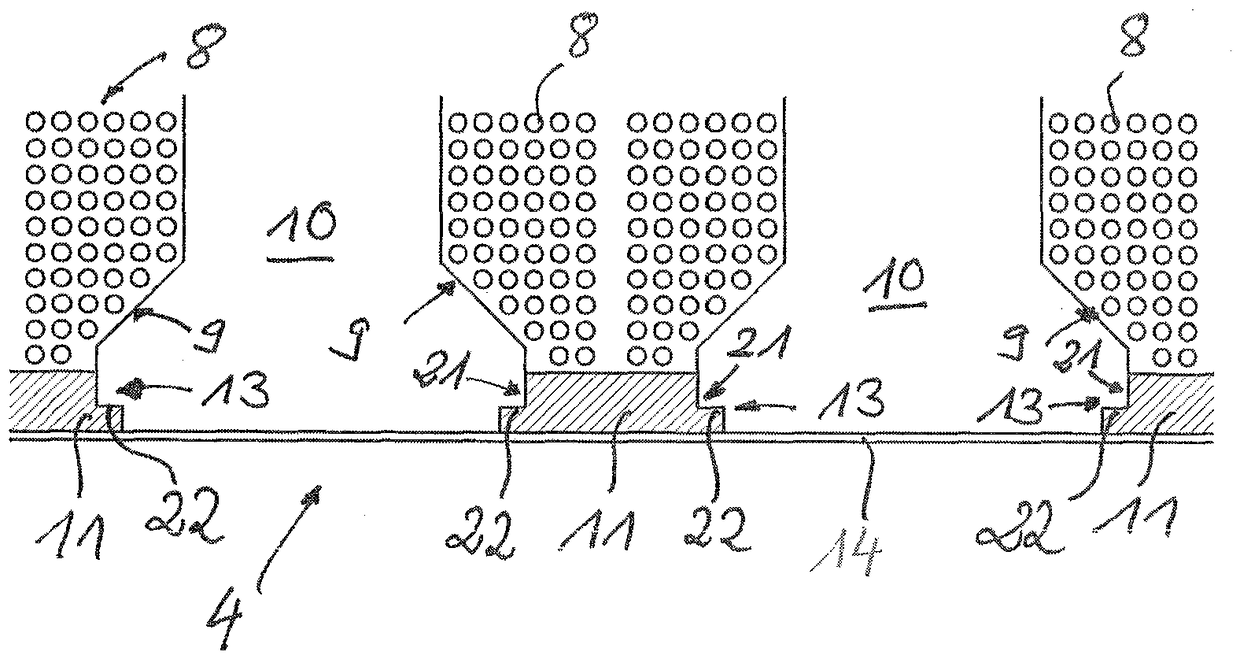

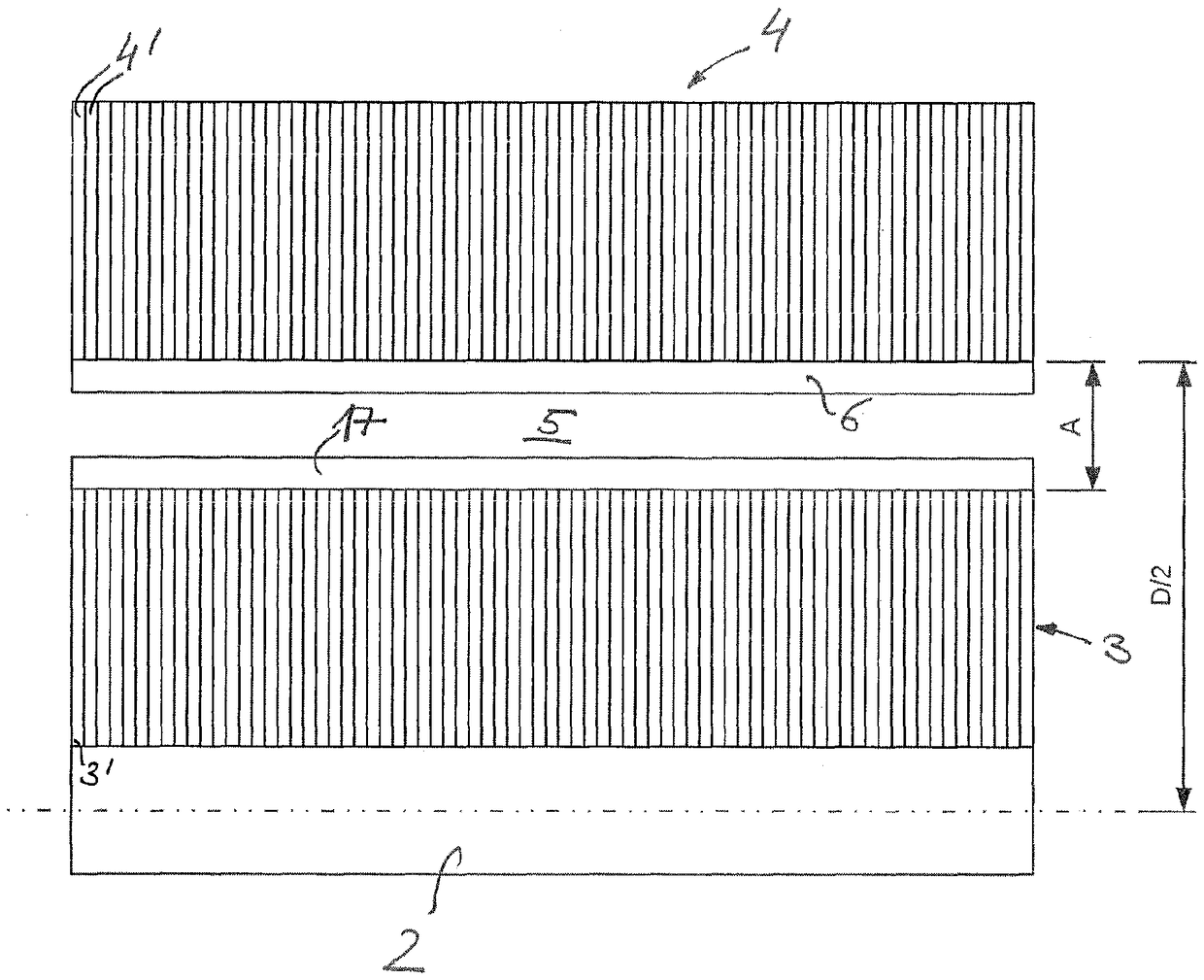

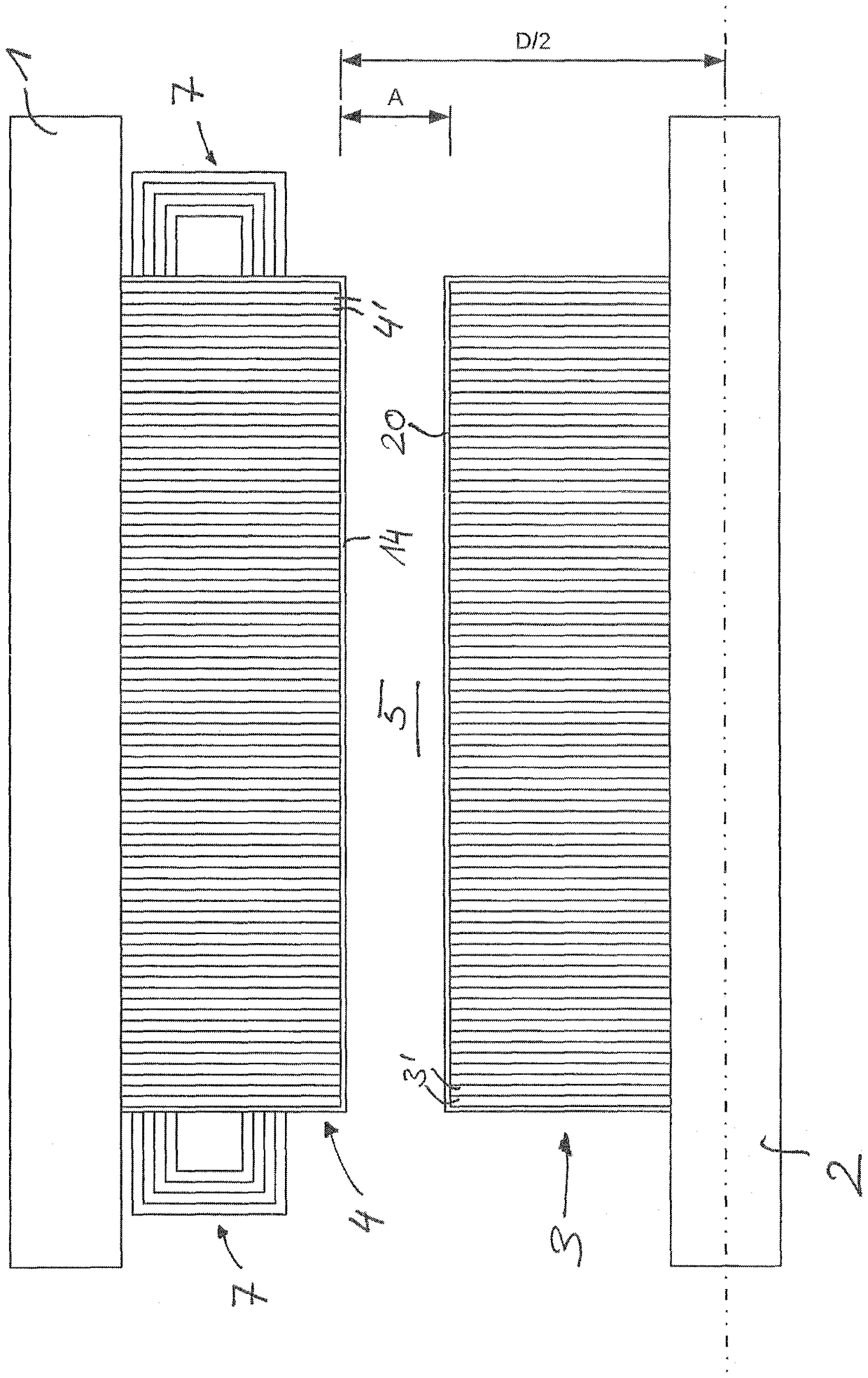

[0037] The following descriptions refer to, but are not limited to, circulator pumps and are generally applicable to any form of centrifugal pump. Figures 1 to 4 Different embodiment variants of the circulating pump are shown, and the figures show, in particular, a partial sectional view of a synchronous reluctance motor used for driving the circulating pump as an integral part of the pump housing. The basic construction is the same for all variants, ie the drive unit comprises a motor housing 1 with a mounted shaft 2 . Mounted on the shaft is a rotor 3 which runs in a stator bore of an outer stator 4 . Both the rotor 3 and the stator 4 consist of individual plate-like laminations 3 ′, 4 ′ respectively stacked in the axial direction to form a lamination pack. An air gap 5 is located between the rotor core 3 and the stator core 4 . According to the Vagati-Design of US Pat. No. 5,818,140, the plate-like laminae 3' of the rotor 3 are preferably provided with flux suppression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com