A kind of wet gas generator and its preparation method

A generator and moisture technology, applied in generators/motors, generators that convert kinetic energy into electrical energy, electrical components, etc., can solve problems such as low output power density, achieve high power output density, and be easy to process and manufacture in large quantities. , easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

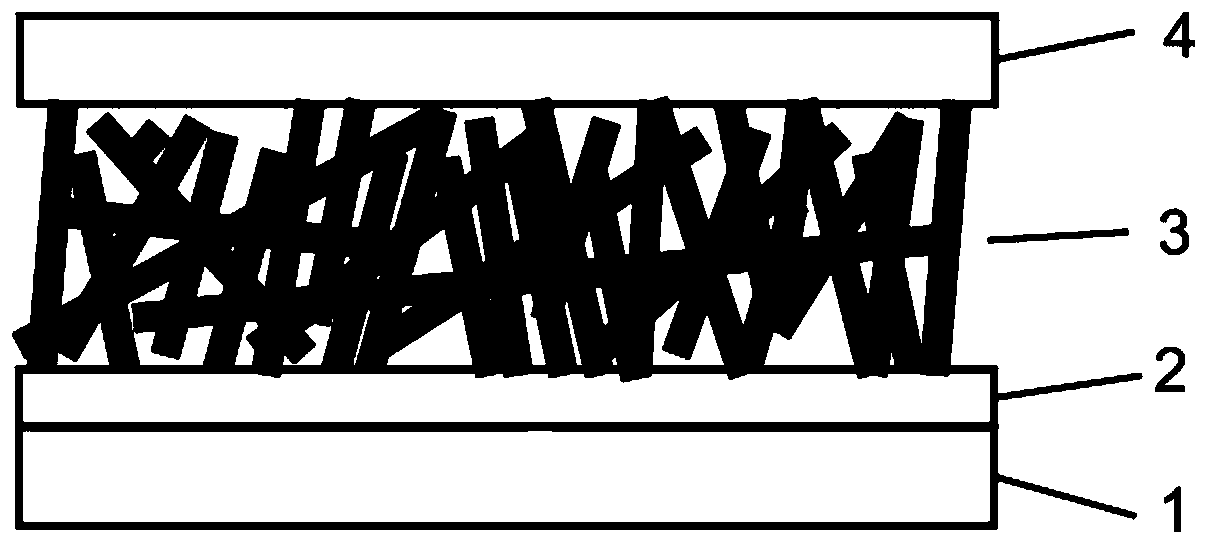

[0046] This embodiment provides a kind of moisture generator, its structure is as follows figure 1 shown. The moisture generator includes a substrate 1, a first electrode 2, a nanowire layer 3, and a second electrode 4, wherein:

[0047] The substrate is a flexible substrate made of polyethylene terephthalate, with a size of 1 cm x 1 cm and a thickness of 50 microns;

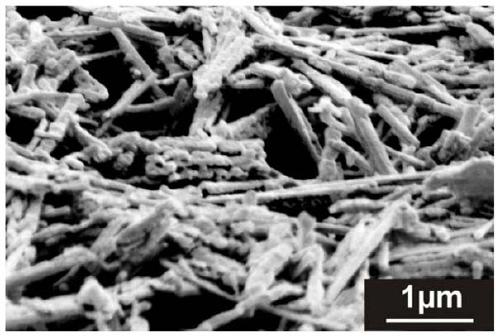

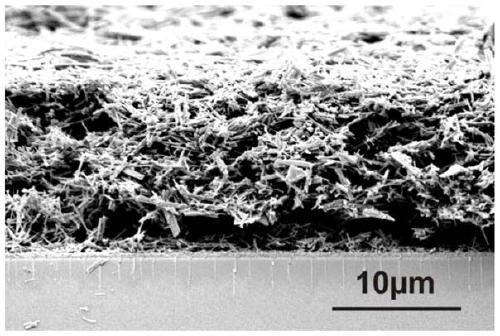

[0048] The first electrode is layered, which is an indium tin oxide film with a thickness of 300 nanometers;

[0049] The material of the nanowire layer is titanium dioxide nanowires, its diameter is distributed in 70-300 nanometers, and the thickness of the nanowire layer is 10 microns; the nanowires cross each other to form a titanium dioxide nanowire network structure; the morphology of the titanium dioxide nanowires and the cross section of the coating Respectively as figure 2 and image 3 Shown; TiO nanowire network structure has good hydrophilicity, and the wetting angle with water is 13 degrees, such...

Embodiment 2

[0065] This embodiment provides a kind of moisture generator, its structure is as follows figure 1 shown. The moisture generator includes a substrate 1, a first electrode 2, a nanowire layer 3, and a second electrode 4, wherein:

[0066] The substrate is glass with a thickness of 1 mm and its dimensions are 1 cm x 1 cm;

[0067] The first electrode is layered, which is fluorine-doped tin oxide, and has a thickness of 300 nanometers;

[0068] The material of the nanowire layer is titanium dioxide nanowires, the diameter of which is distributed in the range of 70-300 nanometers, and the thickness of the nanowire layer is 10 microns;

[0069] The second electrode is layered, made of aluminum, and has a thickness of 100 nanometers.

[0070] The wet gas generator is prepared according to the following steps:

[0071] forming a first electrode on the substrate by magnetron sputtering;

[0072] Electrophoretic deposition is used to form a nanowire layer on the surface of the fi...

Embodiment 3

[0085] The moisture generator of Example 1 can be pasted near the nasal cavity or oral cavity of the human body for real-time monitoring of the respiratory rate of the human body. The output voltage of the moisture generator is related to the respiratory frequency and respiratory intensity, and the output voltage can be used to characterize the human respiratory rate.

[0086] Stick the moisture generator in Example 1 as a sensor at a distance of 8 mm from the nasal cavity, and the voltage output at both ends of the sensor changes as follows during the breathing process of a healthy human body. Figure 11 shown. It can be seen from this that the frequency of the voltage pulse signal output by the sensor is consistent with the breathing frequency of the human body, and the voltage pulses can be clearly separated. The voltage signal generated by the sensor itself can be used to characterize the breathing condition, and no external power supply is required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com