Automatic production device for relay armature

A technology for producing devices and relays, which is applied to relays, circuits, electrical components, etc., can solve problems such as the processing and production efficiency of armatures affecting relays, and achieve the effects of improving automatic production efficiency, improving plug-and-fixing efficiency, and reducing the difficulty of fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

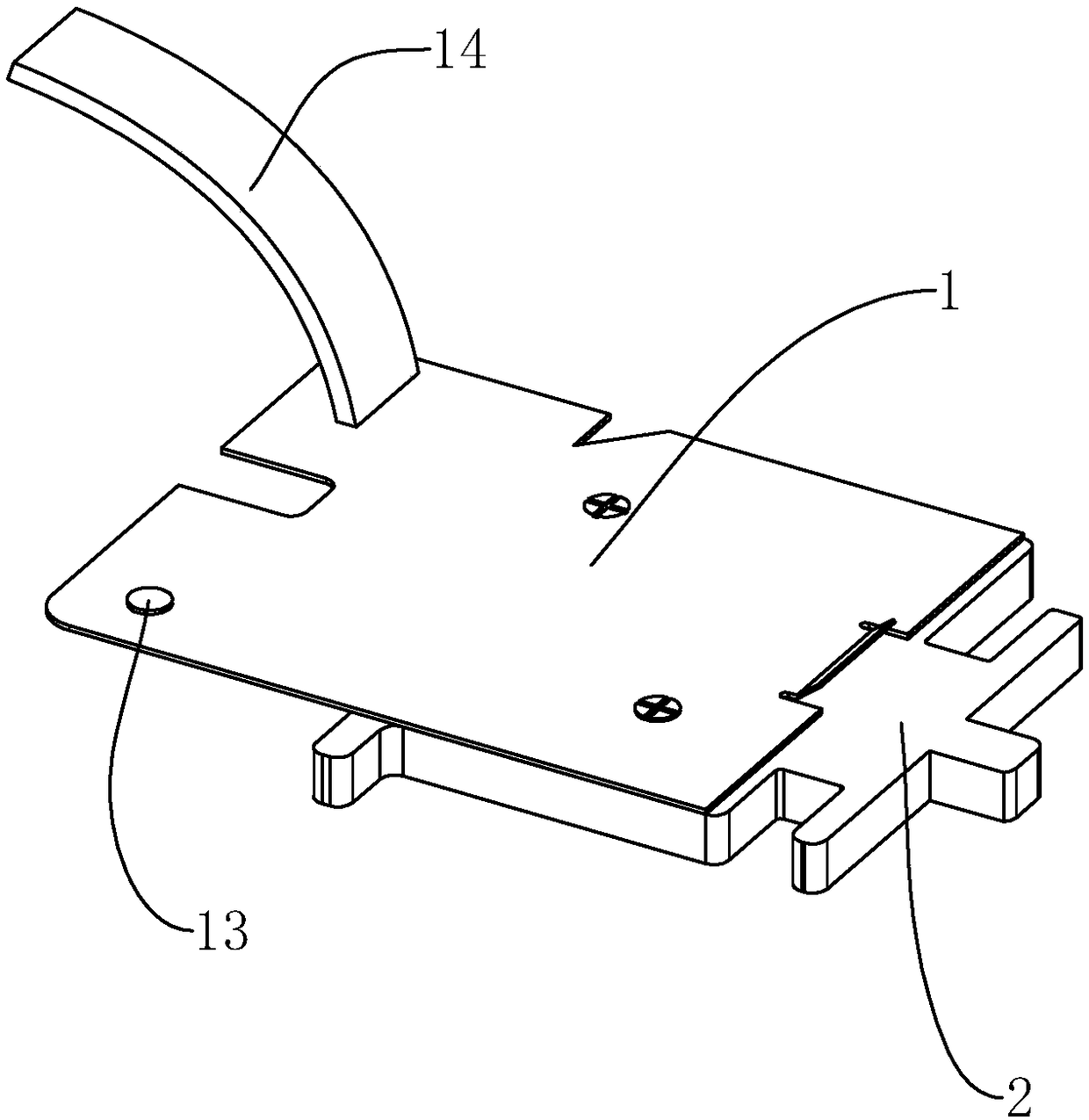

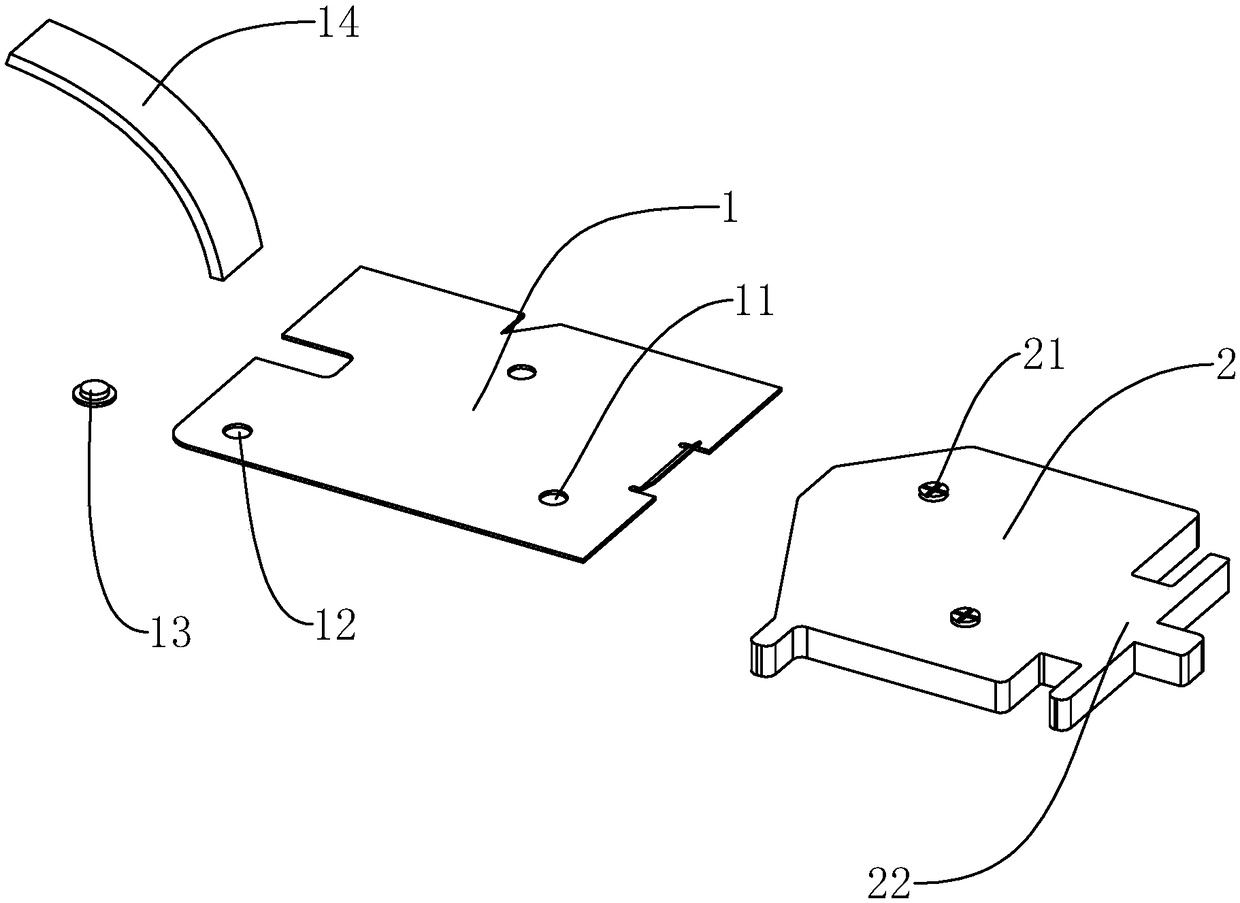

[0043] Such as figure 1 , figure 2 As shown, an armature of a relay includes a main piece 1 as an abutment end of an iron core and an auxiliary piece 2 as an abutment end of a yoke iron. One end of the main piece 1 is provided with a contact insertion hole 12 for installing a fixed contact post 13 , and two fixing holes 11 staggered from each other for installing and fixing the main piece 1 and the secondary piece 2 are provided on the main piece 1 . It should be mentioned that the connecting copper wire 14 is welded and fixed on the main piece 1 . In addition, two fixing pins 21 are provided on the sub-piece 2 and are respectively inserted into the corresponding fixing holes 11 to be squeezed and deformed to be integrally connected with the main piece 1 . In addition, a choke connecting end 22 connected to the choke is provided at the end of the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com