Ceramic ethylene propylene insulating medium-voltage fireproof cable and processing technology thereof

A technology of ethylene-propylene insulated and fire-resistant cables, which is applied in the direction of insulated cables, power cables, insulated conductors, etc., and can solve the problems of ceramic sintered layer not producing heat insulation function, manufacturing cost, large outer diameter and weight, and complex structure of medium-voltage fire-resistant cables and other issues, to achieve good fire resistance, reduce outer diameter and weight, and reduce the cost of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

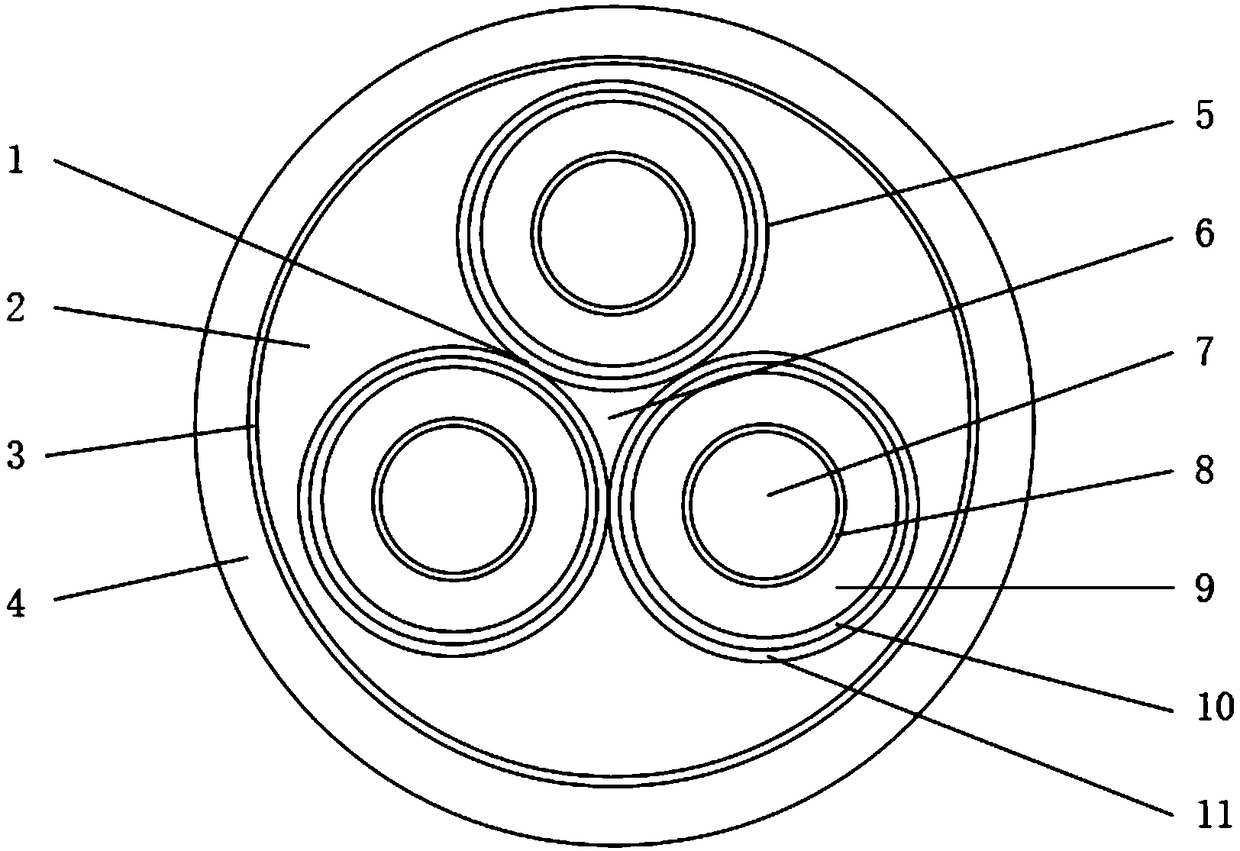

[0037] Such as figure 1 As shown, a ceramic ethylene-propylene insulated medium-voltage fire-resistant cable with a rated voltage of 6kV to 35kV provided by the present invention includes a cable core 1, an inner sheath 2 extruded outside the cable core, and an inner sheath wrapped outside the inner sheath. The armor layer 3 and the outer sheath 4 extruded outside the armor layer, wherein the cable core 1 is cabled by three insulated wire cores 5 and a center filling 6, and the insulated wire cores 5 are sequentially composed of It consists of a conductor 7, a conductor shielding layer 8, an insulating layer 9, an insulating shielding layer 10, and a metal shielding layer 11 wrapped outside the insulating shielding layer.

[0038] The metal shield is braided with metal wires, the inner sheath is made of thermosetting cross-linked polyolefin, the armor layer is made of tinned copper wire braided armor, and the outer sheath is made of thermosetting cross-linked polyolefin.

[0...

Embodiment 2

[0056] The implementation is roughly the same as in Example 1, the difference being:

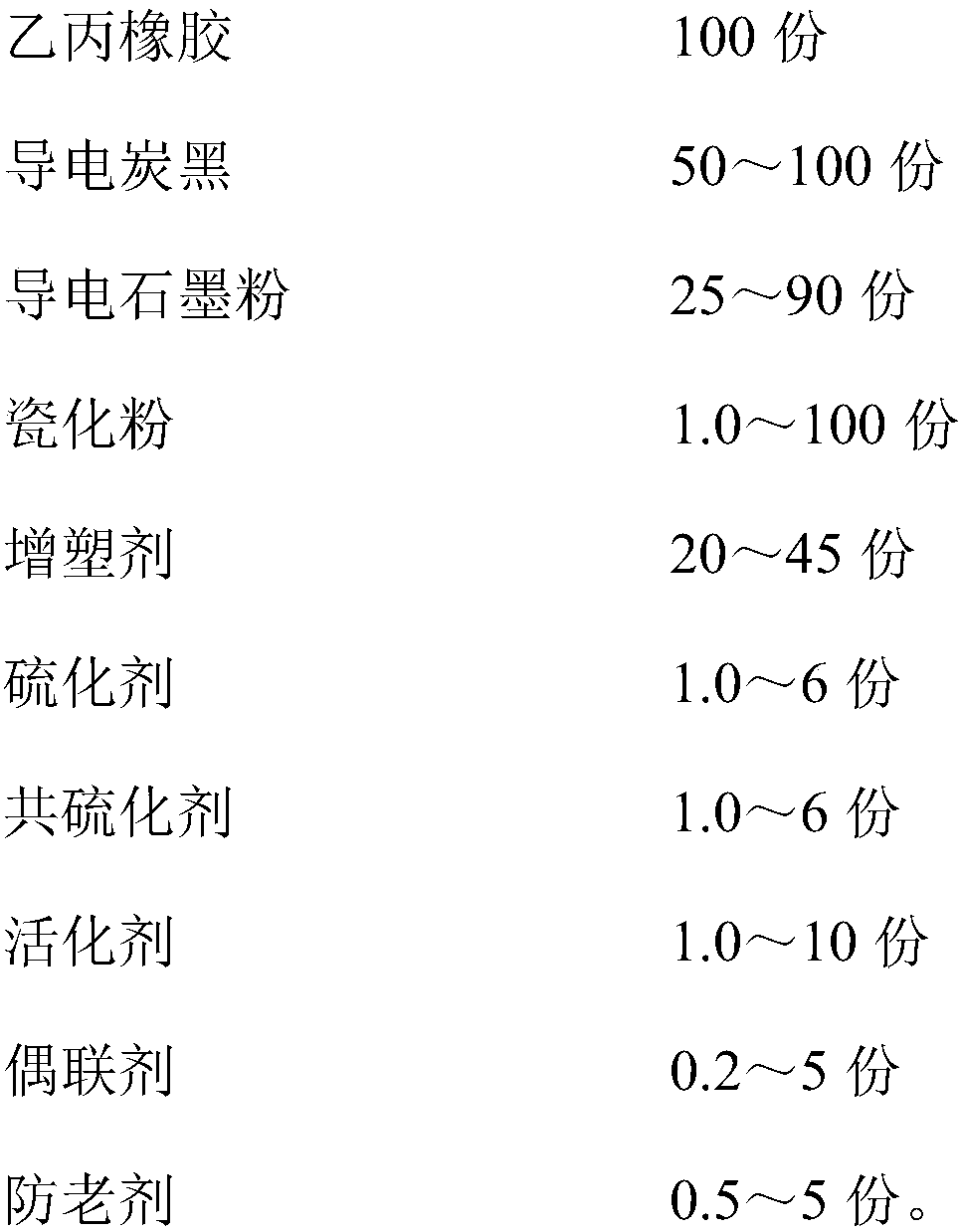

[0057] The material weight components of the ceramic conductor shield or ceramic insulation shield based on ethylene propylene are:

[0058]

[0059] The material weight components of the ceramicized ethylene-propylene insulation based on ethylene-propylene are:

[0060]

[0061]

[0062] The ethylene-propylene rubber is KEP-510, the third monomer is ethylidene norbornene, the ethylene content is 70%, and the Mooney viscosity (ML1+4, 125° C.) is 25.

[0063] The conductive carbon black is YD-280C and HG-1P conductive carbon black, the mixing ratio of the two is 5:1, which can achieve better conductor performance and processing performance.

Embodiment 3

[0065] The implementation is roughly the same as in Example 1, the difference being:

[0066] The material weight components of the ceramic conductor shield or ceramic insulation shield based on ethylene propylene are:

[0067]

[0068]

[0069] The material weight components of the ceramicized ethylene-propylene insulation based on ethylene-propylene are:

[0070]

[0071] The ethylene-propylene rubber is KEP-510, the third monomer is ethylidene norbornene, the ethylene content is 80%, and the Mooney viscosity (ML1+4, 125° C.) is 28.

[0072] The conductive carbon black is YD-280C and HG-1P conductive carbon black, the mixing ratio of the two is 6:1, which can achieve better conductor performance and processing performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com