A kind of high temperature smokeless boiler and combustion method

A combustion method and high-temperature technology, applied in high-temperature gasification smokeless furnaces, high-temperature smokeless boilers and combustion fields, can solve the problems of high nitrogen oxides at the boiler outlet, high smoke and dust emissions, increased boiler operating costs, and low thermal energy utilization. Achieve remarkable energy saving effect, improve heat energy release efficiency, and high heat energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

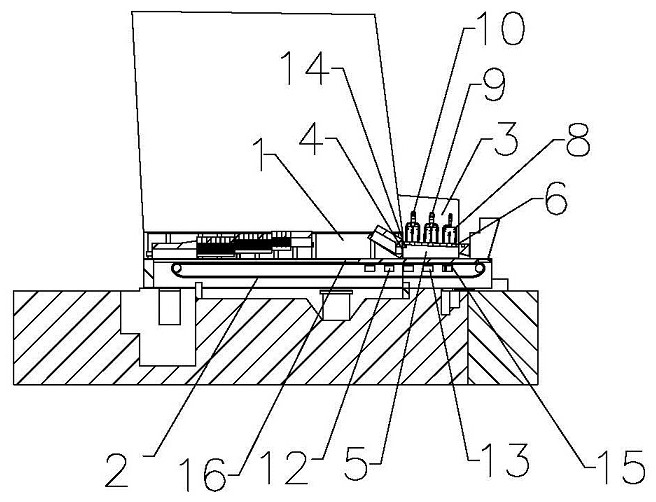

[0050] Example 1, such as figure 1 , 2As shown, a high-temperature smokeless boiler includes a combustion chamber and a fire grate 2, and the fire grate 2 is arranged at the lower part of the combustion chamber; the combustion chamber includes a main combustion chamber 1 and an auxiliary combustion chamber 3, and the auxiliary combustion chamber 3 is arranged in the main combustion chamber 1 on the coal inlet side. The main combustion chamber 1 and the auxiliary combustion chamber 3 are set relatively independently, and can also be integrated. In this embodiment, the auxiliary combustion chamber 3 and the main combustion chamber 1 are set relatively independently.

[0051] A baffle plate 4 is arranged between the auxiliary combustion chamber 3 and the main combustion chamber 1, and communicates with each other through the baffle plate 4. The baffle plate 4 makes the auxiliary combustion chamber 3 form a semi-closed state, and the baffle plate 4 can be used to turn the auxilia...

Embodiment 2

[0057] Embodiment 2, on the basis of embodiment 1, the bottom end of the fire grate at the bottom of the main combustion chamber 1 is also provided with a lower spraying device, which can also be realized to be the same or even the same as that at the bottom of the fire grate at the bottom of the auxiliary combustion chamber 3. Better technical effects.

[0058] The bottom of the fire grate 2 corresponding to the lower part of the main combustion chamber 1 can also be provided with a lower air supply device 13 , and at this time, the lower spraying devices 12 and the lower air supply devices 13 are arranged in a staggered manner.

Embodiment 3

[0059] Embodiment 3, on the basis of Embodiment 1 or / and Embodiment 2, an upper spraying device 14 is provided in the auxiliary combustion chamber 3 behind the air supply module along the fuel inlet direction, and it can also be realized with the lower part of the auxiliary combustion chamber 3. The bottom of the fire grate is provided with the same or even better technical effect of the lower spraying device 12.

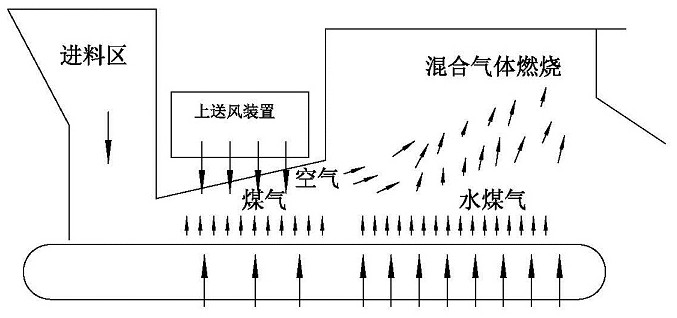

[0060] The combustion method of the above coal-fired boiler burner includes a first combustion process and a second combustion process;

[0061] During the first combustion process:

[0062] The fuel is in the stage of coking and volatile release;

[0063] The fire grate carrying fuel is the low temperature section fire grate 15;

[0064] Fuel combustion is carried out in the auxiliary combustion chamber 3, and along the direction of fuel intake, there are three processes in sequence: low temperature zone, high temperature zone and gasification zone:

[0065] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com