Water-resistant antibacterial bamboo fiber non-woven fabric surface layer and preparation method thereof

A bamboo fiber, cloth surface layer technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of no antibacterial, poor water conductivity, low dryness of the surface layer of sanitary napkins, etc., to maintain water resistance and hydrophilicity, Enhance the effect of hydrophobicity and excellent water conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the described water-resistant and antibacterial bamboo fiber non-woven fabric surface layer may further comprise the steps:

[0032] S1: Natural food soybean protein fiber 2.5%-5%, corn protein fiber 2.0%-3.0%, sugarcane fiber 0.5%-1.6%, potato starch 0.2%-0.8%, wheat starch 0.2%-8%, water 1% -2.5%, Turkish red oil 0.2%-0.6%, cottonseed oil 0.3%-0.8%, mix well, stir well, then gradually heat, first set the heating temperature to 25°C, then heat in turn at 5°C, 10°C, 15°C ℃, the heating time interval is 5min, until the heating temperature reaches 55℃, maintain for 30min, and a slightly pasty mixture is obtained;

[0033] S2: Mix the slightly pasty mixture with the bamboo fiber in a weight ratio of (4-8): (92-96), and then fully stir evenly to obtain a material body;

[0034] S3: The mixed material body is made into a base fabric through a spunlace process, and a water-resistant and antibacterial bamboo fiber non-woven surface layer can be prepa...

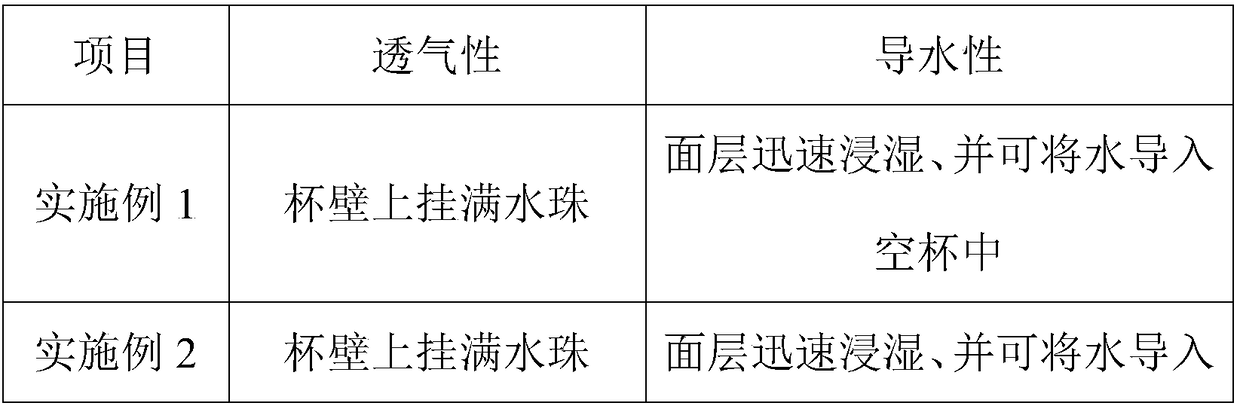

Embodiment 1

[0037] A water-resistant and antibacterial bamboo fiber non-woven surface layer, the surface layer comprises the following raw materials in weight ratio: 90% of bamboo fiber, 4% of soybean protein fiber, 3% of corn protein fiber, 0.8% of sugarcane fiber, and 0.2% of potato starch , Wheat Starch 0.8%, Water 1%, Turkey Red Oil 0.2%, Cottonseed Oil 0.3%.

[0038] The preparation method of the described water-resistant and antibacterial bamboo fiber non-woven fabric surface layer may further comprise the steps:

[0039] S1: Mix natural food soybean protein fiber 4%, corn protein fiber 3%, sugarcane fiber 0.8%, potato starch 0.2%, wheat starch 0.8%, water 1%, turkey red oil 0.2%, cottonseed oil 0.3%, and stir well After uniformity, gradually heat, first set the heating temperature at 25°C, then heat at 5°C, 10°C, and 15°C in sequence, with a heating time interval of 5 minutes, until the heating temperature reaches 55°C and maintain for 30 minutes to obtain a slightly pasty mixture...

Embodiment 2

[0043] A water-resistant and antibacterial bamboo fiber non-woven surface layer, the surface layer comprises the following raw materials in weight ratio: 94% bamboo fiber, 2.5% soybean protein fiber, 2.8% corn protein fiber, 0.5% sugarcane fiber, 0.8% potato starch , wheat starch 0.3%, water 2.5%.

[0044] The preparation method of the described water-resistant and antibacterial bamboo fiber non-woven fabric surface layer may further comprise the steps:

[0045] S1: Mix natural food soybean protein fiber 2.5%, corn protein fiber 2.8%, sugarcane fiber 0.5%, potato starch 0.8%, wheat starch 0.3%, water 2.5%, after fully stirring, gradually heat, first set the heating The temperature is 25°C, and then heated at 5°C, 10°C, and 15°C in sequence, with a heating time interval of 5 minutes, until the heating temperature reaches 55°C and is maintained for 30 minutes to obtain a slightly pasty mixture;

[0046] S2: Mix the slightly pasty mixture with the bamboo fiber at a weight ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com