Method for continuous VGF crystal growth through rotation after horizontal injection synthesis

A crystal growth, horizontal technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of slow rotation, cumbersome and complicated growth process, difficult industrialization, etc., and achieve easy operation, simplified process, easy operation and The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following, the method and supporting equipment provided by the present invention for horizontal injection synthesis and rotation continuous VGF crystal growth are described in detail through specific examples, so as to facilitate understanding, but do not limit the present invention in any form, those skilled in the art carry out according to the technical scheme Improvements, modifications or similar replacements should all be included within the protection scope of the present invention.

[0035] device embodiment

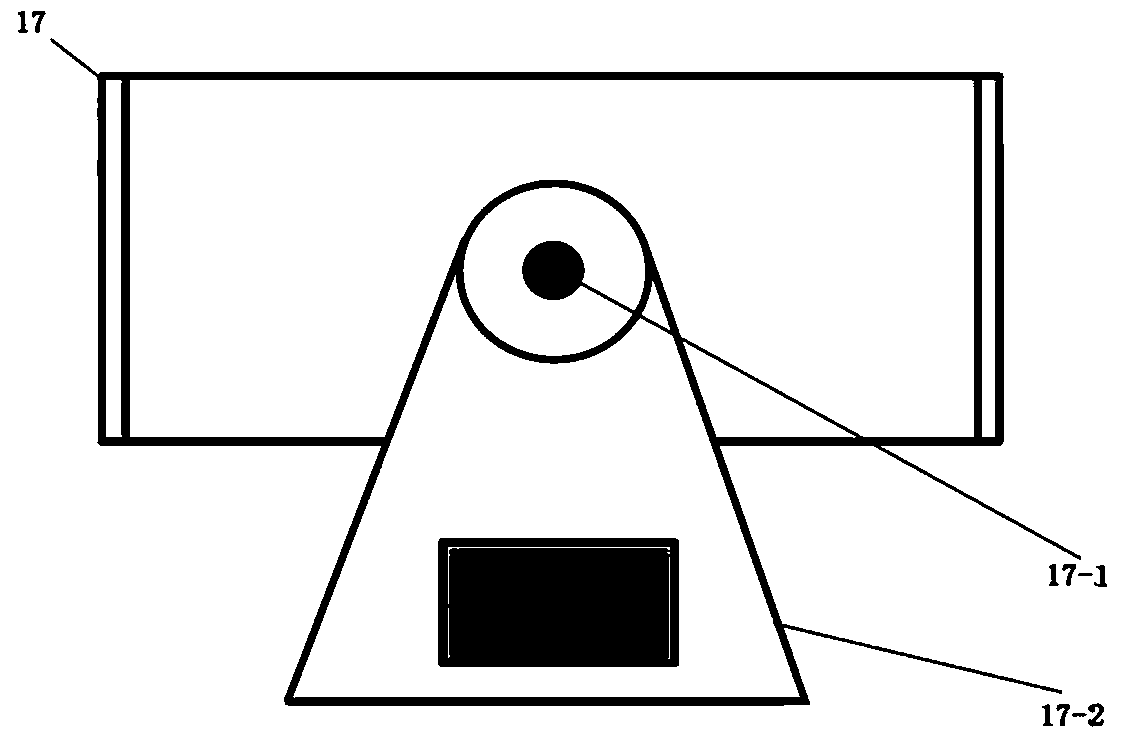

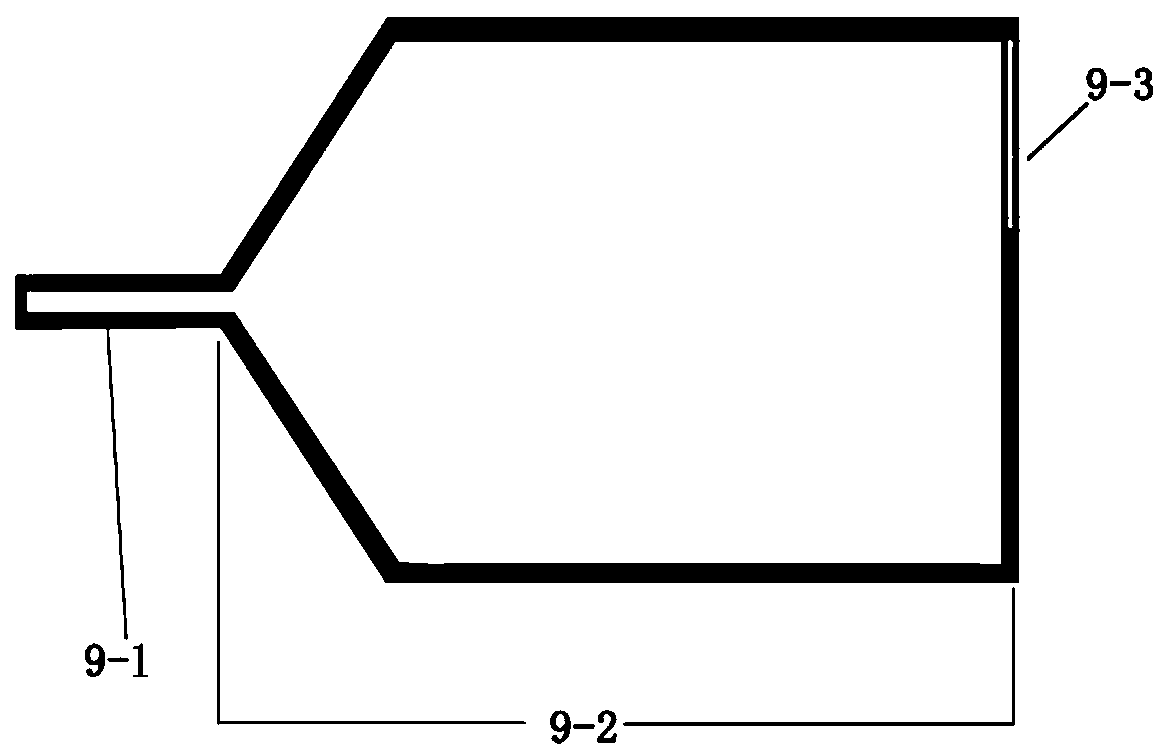

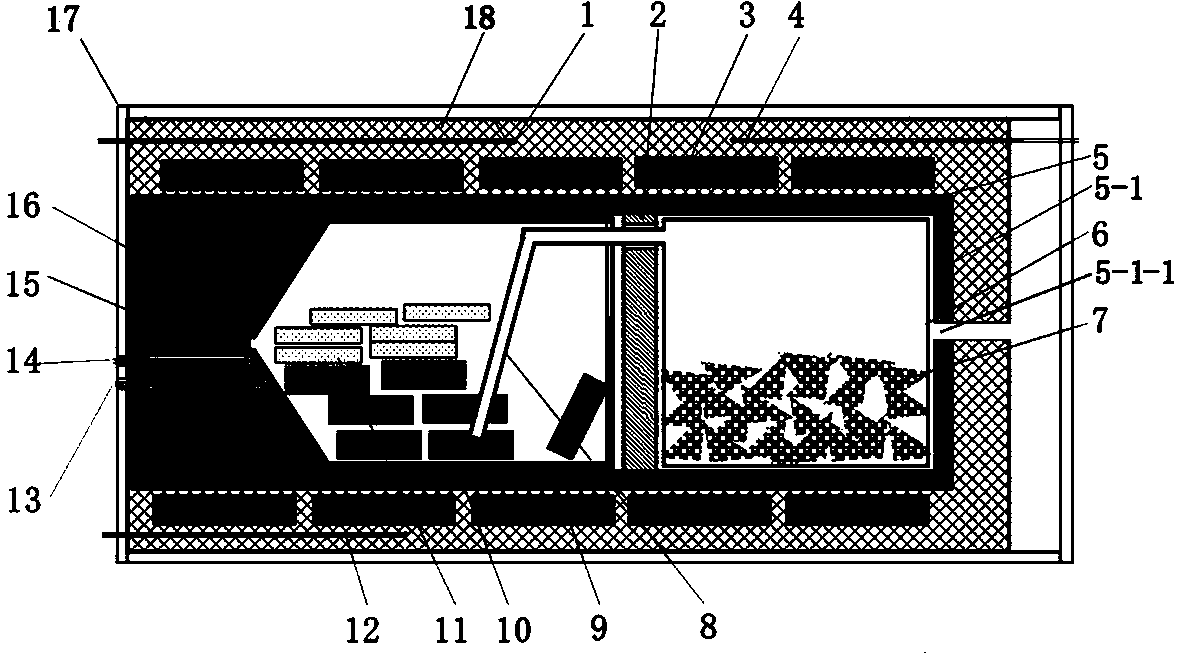

[0036] This embodiment provides a device for rotating continuous VGF crystal growth after horizontal injection synthesis, see figure 1 , the equipment structure includes a furnace body 17, a crystal synthesis growth system positioned in the furnace chamber of the furnace body 17 and its supporting heating system, temperature measurement system and heat preservation system, and the furnace body 17 is provided with a sealed cover to form a closed cavi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com