System and method for making hydrogen through ammonia electrolysis and applying hydrogen to coal liquefaction

A technology of coal liquefaction and electrolyte, which is applied in the field of coal liquefaction system, can solve the problems of high cost, limit the promotion of electrolytic hydrogen production method, and consume electric energy, etc., and achieve the effect of reducing overall cost, promoting clean and efficient utilization, and reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

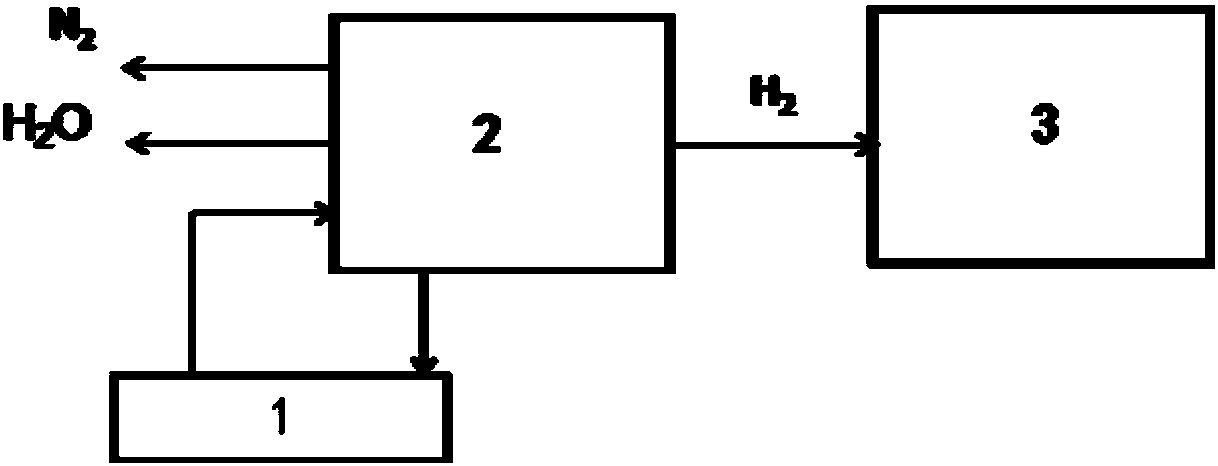

[0043] Such as figure 1 As shown, the cathode of the electrolytic cell 2 is a Ni-Co-Fe alloy electrode, the anode is a Ni-Rh alloy electrode, and the composition of the alkaline electrolyte is: 1mol / L KOH, 1mol / L NH 3 . The ammonia in the alkaline electrolyte is supplemented by industrial ammonia water. Such as figure 2 As shown, the alkaline electrolyte prepared in the electrolyte supply system 1 is pumped into the electrolytic cell 2, and an electrolytic reaction occurs under an applied voltage of 0.8V, and a high-purity electrolyte with a purity of 99.9% is produced at the cathode of the electrolytic cell 2. Hydrogen, nitrogen and water with low ammonia content are produced at the anode of electrolytic cell 2. The high-purity hydrogen gas produced at the cathode of the electrolytic cell 2 enters the coal liquefaction system 3, and undergoes a hydrogenation catalytic reaction with the coal slurry under high temperature and high pressure to produce naphtha and diesel oil,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com