Tension setting method of vertical continuous annealing furnace

A technology of continuous annealing furnace and setting method, which is applied in the field of iron and steel smelting, and can solve problems such as strip steel is easy to deviate, achieve the effects of no deviation, solve scratches in the strip steel furnace, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

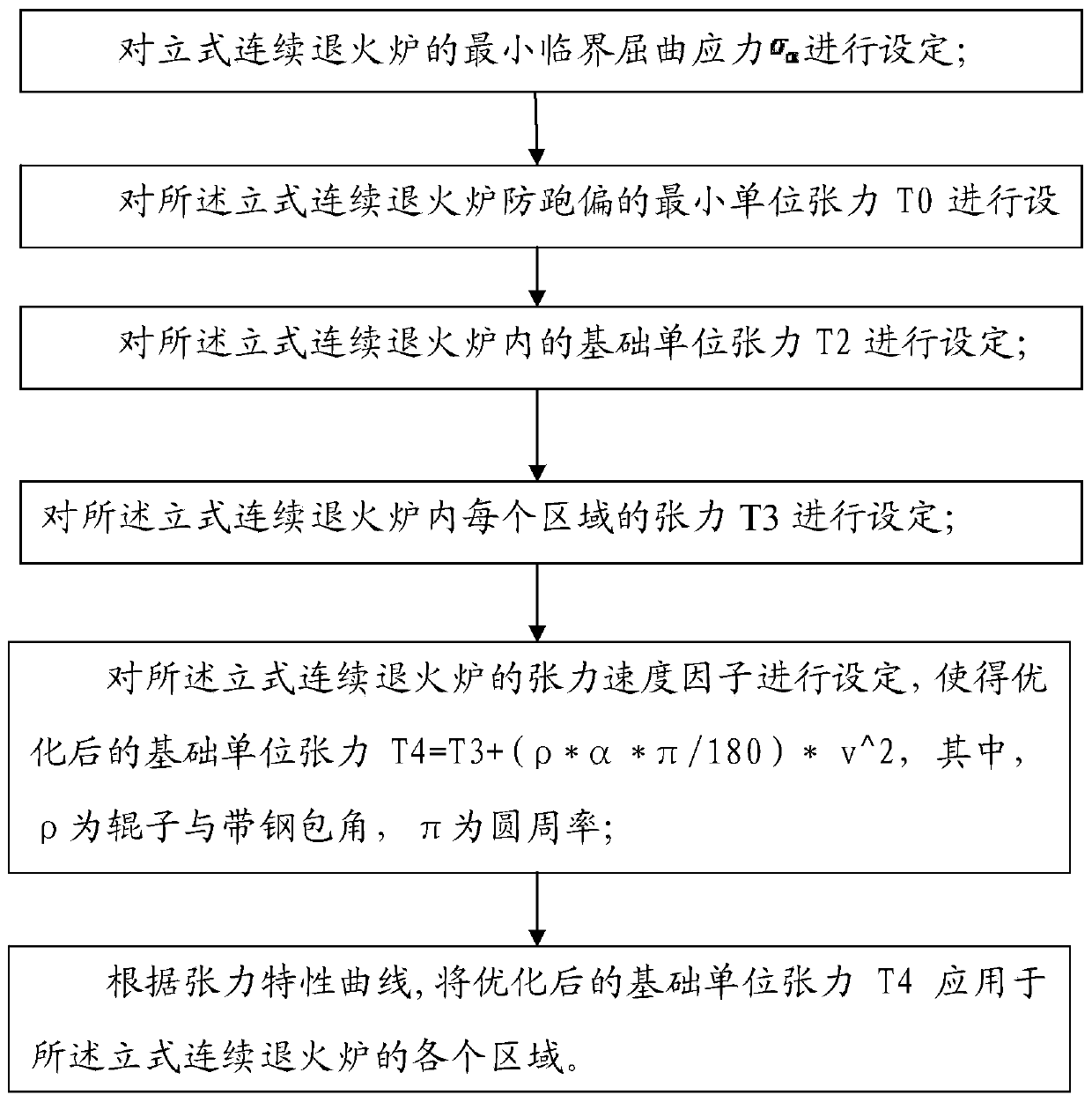

[0033] like figure 1 As shown, the embodiment of the present invention provides a method for setting the tension of a vertical continuous annealing furnace, including:

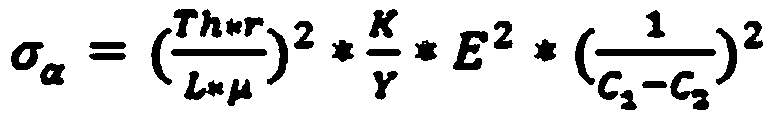

[0034] Step S1: The minimum critical buckling stress σ of the vertical continuous annealing furnace α make settings;

[0035] Step S2: setting the minimum unit tension T0 for preventing deviation of the vertical continuous annealing furnace;

[0036] Step S3: Set the basic unit tension T2 in the vertical continuous annealing furnace; the basic unit tension T2 satisfies F*T0α ), where K is the safety factor against bending, and F is the safety factor against deviation.

[0037] Step S4: Set the tension T3 of each area in the vertical continuous annealing furnace; make the tension T3 of each area satisfy T3=T2*F, where F is the safety factor for preventing deviation.

[0038] Step S5: Set the tension speed factor of the vertical continuous annealing furnace so that the optimized basic unit tension T4=T3+(ρ*α*...

Embodiment 2

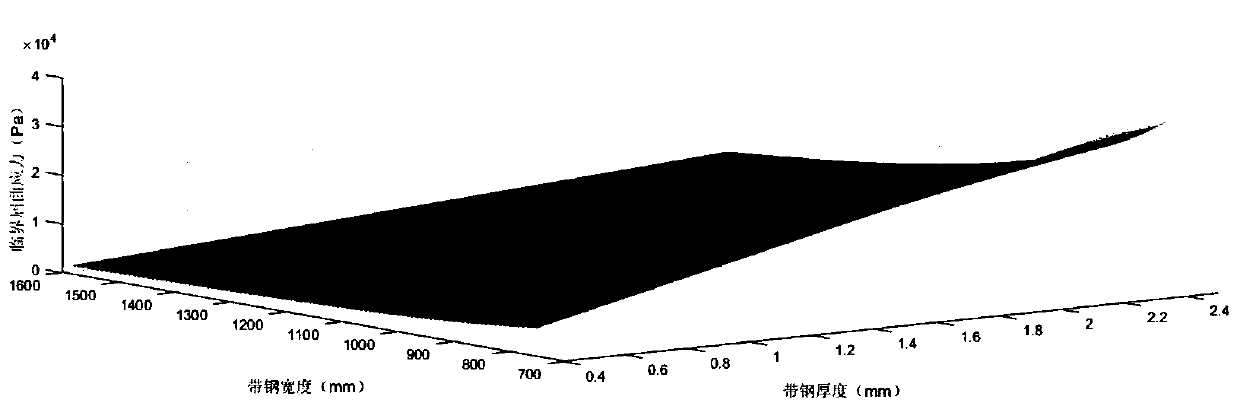

[0068] For example, SGJT2230CAL produces AQ89900R with a specification of 2.0*1600mm. Among them, the carbon equivalent is greater than 0.1, the annealing temperature is greater than 830°C, and the operating speed of the furnace area is 310m / min. Select 10# furnace roll in the heating section, the main parameters are as follows: furnace roll diameter 900mm, friction coefficient 0.025, high temperature yield strength of strip steel 1.0E+7Pa Pa, elastic modulus 1.17E+11Pa, distance between top and bottom rolls 19m. The critical buckling stress σ of different specifications is obtained α ,like figure 2 shown.

[0069] In this embodiment, the annealing temperature is selected at 820-840°C, according to F*T0α ) to obtain the basic unit tension tables of different specifications, as shown in Table 2. Wherein T0=1.9Mpa, F: anti-deviation safety factor 1.57 (1.2-1.6) K: anti-deviation safety factor 1.23 (1.2-1.4), W in Table 2 is strip width, t is strip thickness.

[0070] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com