Method and production line for producing granular fuel and essential fir oil from fir wood dust

A technology for pellet fuel and fir sawdust, which is applied in the field of using fir sawdust to make pellet fuel and fir essential oil, can solve the problems of difficulty in producing market demand, low recycling value, and difficulty in recycling resources, etc., and achieves high utilization value, It is easy to burn, and the effect of improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

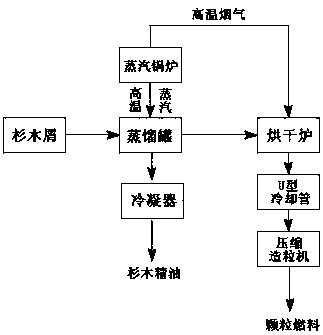

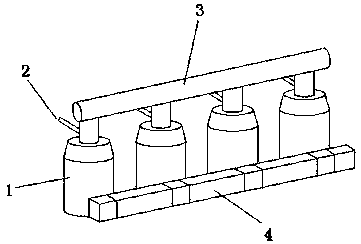

[0028] Example. A method and production line for making granular fuel and Chinese fir essential oil from fir sawdust, such as figure 1 with figure 2 As shown, by passing high-temperature steam into fir chips, distilling and extracting fir essential oil, and then drying and compressing fir chips to make granular fuel.

[0029] The method is as follows: sieving the fir chips, passing high-temperature steam into the fir chips, separating and extracting the fir essential oil by high-temperature steam distillation; drying, cooling and compressing the remaining fir chips to make granular fuel.

[0030] Described fir essential oil is prepared according to the following method:

[0031] (a) Flatten and dry the fir sawdust, and sieve to remove wood blocks and impurities;

[0032] (b) Put fir chips into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com