Preparation method of pyran-type anthocyanin aglycone

A kind of technology of anthocyanin and pyranoid, which is applied in the field of preparation of pyranocyanin aglycon, can solve the problem that it is not suitable for large-scale preparation of pyranocyanin products, and the samples cannot be directly applied to food, medicine and other fields and other issues, to achieve the effect of improved stability and strong tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

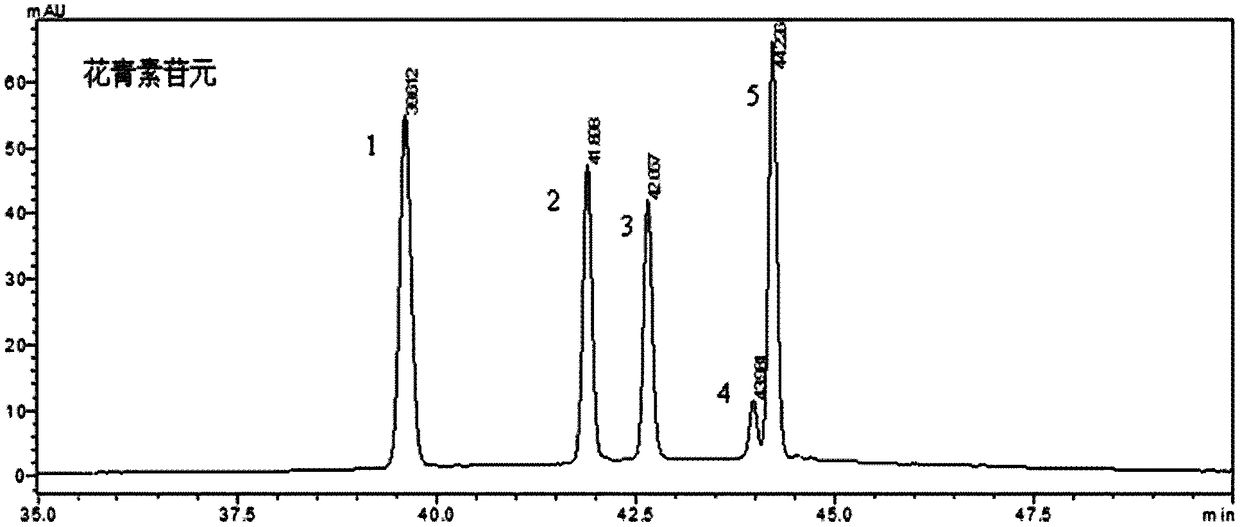

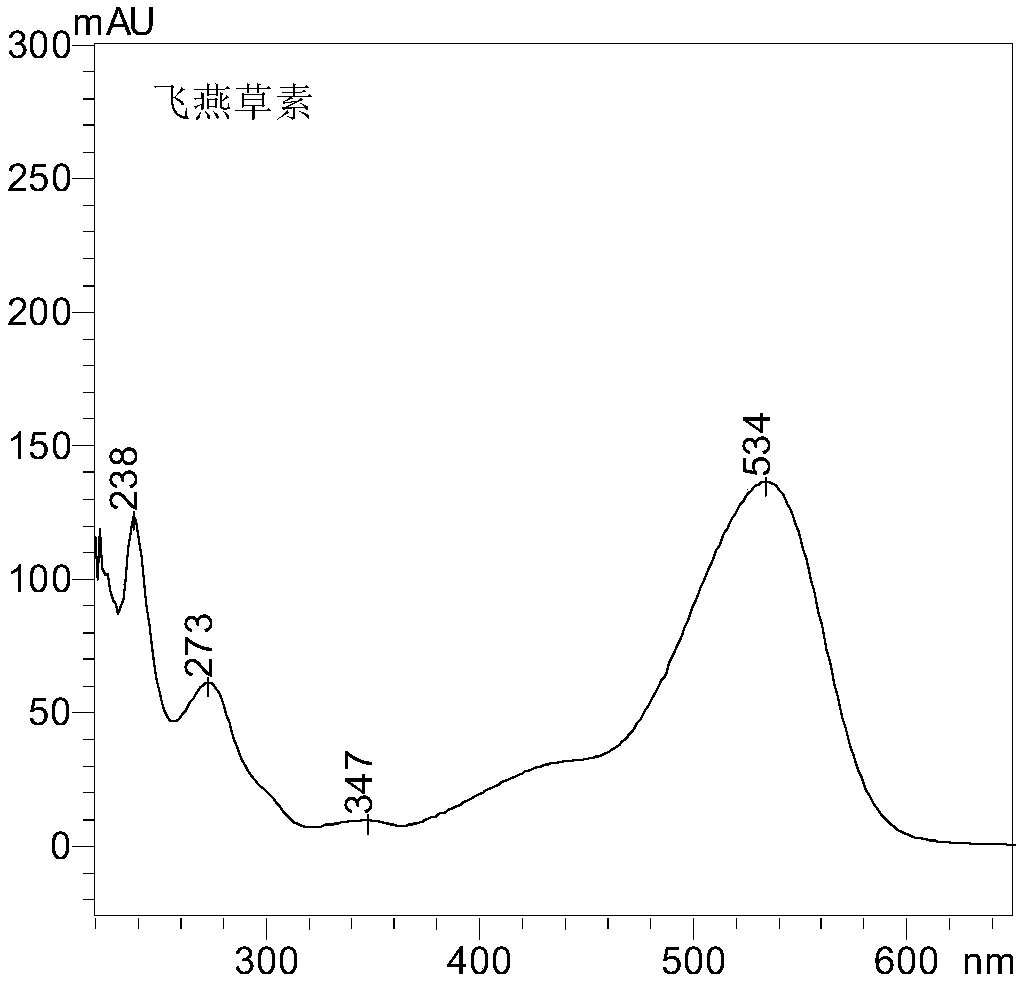

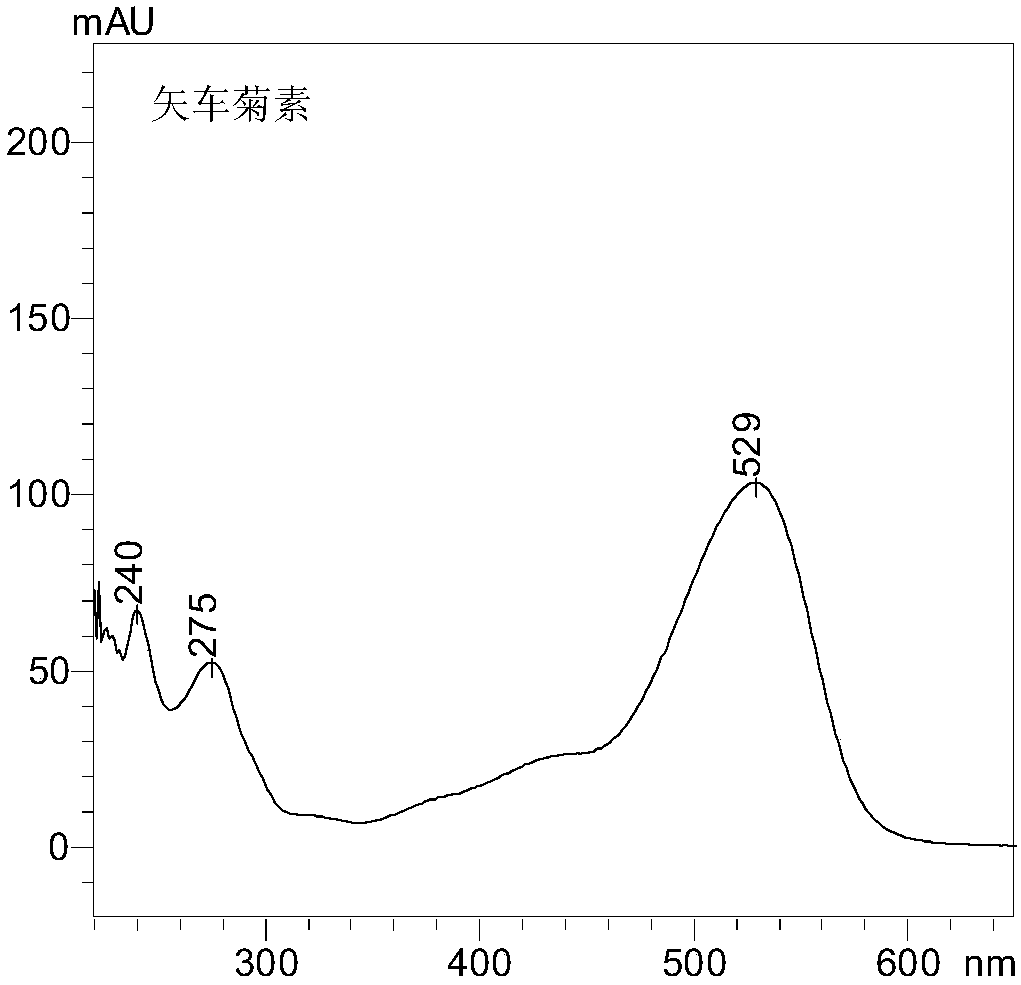

Image

Examples

Embodiment 1

[0041] Step 1. Extraction: crush the frozen blueberry fruit raw material to make a homogenate, add it to a glass container with a cover, add 70% ethanol solution to the blueberry fruit homogenate at a volume ratio of 1:5, and adjust the pH value with hydrochloric acid At 3.0, after stirring for 0.5 hours, soak in closed light at room temperature for 72 hours; filter the extract, and extract the residue twice;

[0042] Step 2. Extraction: Pour the extracted solution concentrated under reduced pressure into a separatory funnel, and perform liquid-liquid extraction with ethyl acetate. time, the time is 24 hours / time, each time the ester layer is first poured from the top, and then the water layer is collected from the bottom for subsequent use;

[0043] Step 3, column chromatography: put part of the anthocyanin extraction solution in the water layer into the Amberlite XAD-7 macroporous resin column by wet method, and the single loading volume is 1 / 10 of the resin volume, and firs...

Embodiment 2

[0048] Step 1. Extraction: crush fresh blueberry fruit raw materials to make a homogenate, add it to a glass container with a cover, add 65% ethanol solution to the blueberry fruit homogenate at a volume ratio of 1:3, and adjust the pH value with hydrochloric acid At 2.5, after stirring for 0.5 hours, soak in closed light at room temperature for 48 hours; filter the extract, and extract the residue 3 times;

[0049] Step 2. Extraction: Pour the extracted solution concentrated under reduced pressure into a separatory funnel, and perform liquid-liquid extraction with ethyl acetate. time, the time is 24 hours / time, each time the ester layer is first poured from the top, and then the water layer is collected from the bottom for subsequent use;

[0050] Step 3, column chromatography: put part of the anthocyanin extraction solution in the water layer into the AB-8 macroporous resin column by wet method, and the single loading volume is 1 / 12 of the resin volume, and first use 0.03% h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com