Preparation method of cumquat and loquat extract

A technology for loquat paste and kumquat, which is applied in the field of preparation of kumquat loquat paste, can solve the problems of loss of effective components, rare loquat paste, high energy consumption, etc., and can reduce browning, improve juice yield and clarity, and improve concentration The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of kumquat loquat extract, comprising the steps of:

[0043] 1) Kumquat treatment:

[0044] a. Raw material processing: select 100kg of fresh kumquats, wash and remove leaves, bellflowers and other sundries, drain the water, and freeze and thaw twice;

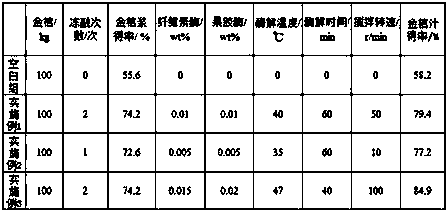

[0045] b. Squeeze: Squeeze the thawed kumquat, filter to obtain kumquat pulp and kumquat residue, wherein the kumquat pulp is 74.2kg, compared with the direct pressing of fresh kumquat, the yield of kumquat pulp is increased by 18.6%;

[0046] c. Enzymolysis: add 0.01wt% cellulase and 0.01wt% pectinase to the kumquat pulp for 60 min, the enzymolysis is carried out under constant temperature and stirring conditions, the enzymolysis temperature is 40 °C, stir The rotation speed is 50r / min; the cellulase and pectinase act synergistically to degrade the cell wall as much as possible, enhance the clarification effect, improve and accelerate the filterability and filtration speed of kumquat pulp, and then...

Embodiment 2

[0062] A preparation method of kumquat loquat extract, comprising the steps of:

[0063] 1) Kumquat treatment:

[0064] a. Raw material processing: select 100kg of fresh kumquats, wash and remove leaves, bellflowers and other sundries, drain the water, freeze and thaw once;

[0065] b. Squeeze: Squeeze the thawed kumquat, filter to obtain kumquat pulp and kumquat residue, wherein the kumquat pulp is 72.6kg, compared with the direct pressing of fresh kumquat, the yield of kumquat pulp is increased by 17%;

[0066] c. Enzymolysis: Add 0.005wt% cellulase and 0.005wt% pectinase to the kumquat pulp for 60 minutes of enzymolysis. The enzymolysis is carried out under constant temperature and stirring conditions. 10r / min;

[0067] d. Centrifugation: Centrifuge the kumquat pulp after enzymatic hydrolysis and take the supernatant, which is kumquat juice. The yield of kumquat juice is 77.2%. Compared with the one without enzymatic treatment, the yield of kumquat juice has increased 19...

Embodiment 3

[0082] Embodiment 3 is similar to the method of embodiment 1, and its difference is:

[0083] Step 1) Add 0.015wt% cellulase and 0.02wt% pectinase, enzymatically hydrolyze for 45min, the enzymolysis temperature is 47°C, the stirring speed is 100r / min, the yield of kumquat juice is 84.9%; Concentrate under pressure to 80% soluble solids, obtain 10.6 kg kumquat concentrate.

[0084] In step 2), the enzyme inactivation time of loquat was 15 minutes, and the obtained loquat syrup was 82.4 kg, which was concentrated to a solid content of 75%, and 9.18 kg of loquat concentrate was obtained.

[0085] In step 3), add water 8 times the mass of the throat-moisturizing auxiliary material, and extract in the reflux extraction tank at 70°C for 1 hour.

[0086] In step 4), kumquat concentrate: loquat concentrate: syrup = 1:1:20, add 10wt% throat-moistening auxiliary material extract, 5 minutes before the end of concentration, add 0.02wt% menthol.

[0087] The relevant experimental data of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com