Storage and separation integration method based on combination of multi-station joint robots and multiple layers of shuttle cars

A multi-station, robot technology, applied in the direction of conveyors, mechanical conveyors, stacking of objects, etc., can solve the problems of affecting the efficiency of warehouse entry and exit, increasing equipment configuration, increasing logistics links, etc., to reduce the number of dismantling and palletizing operations , Improve system flexibility and increase storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

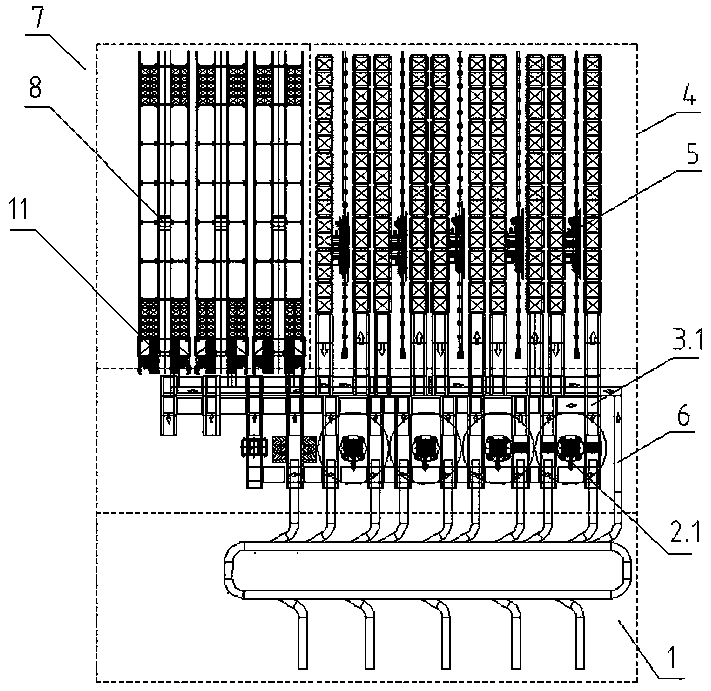

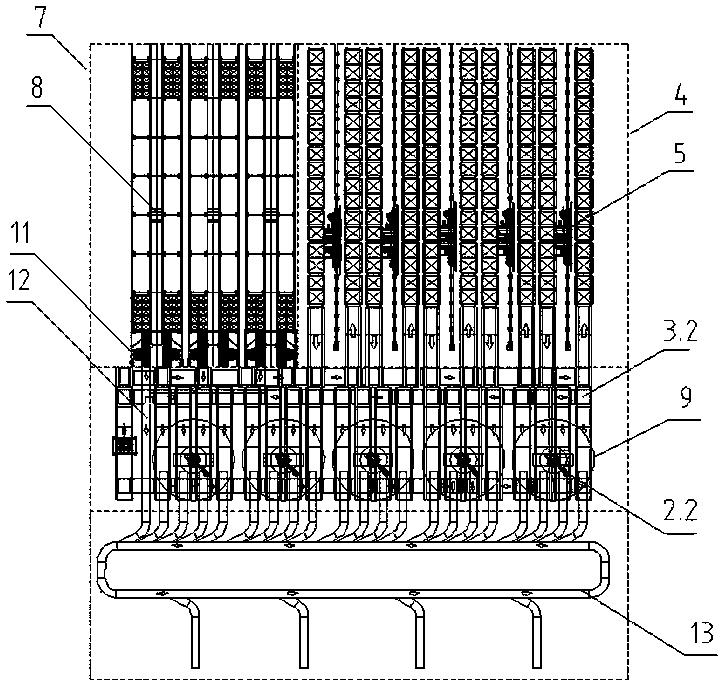

[0021] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

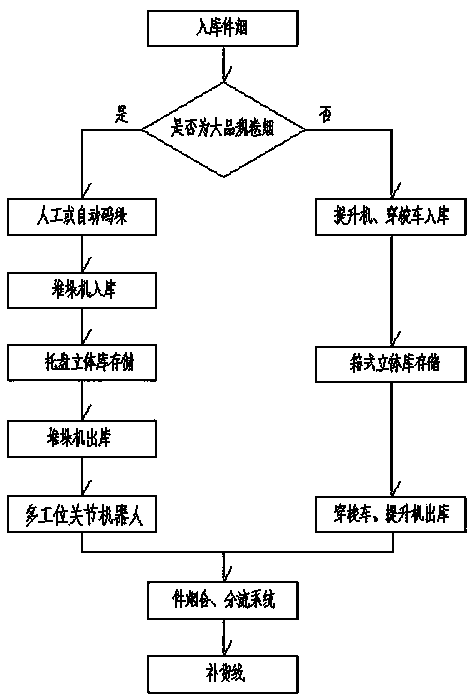

[0022] Such as Figure 1-4 As shown, the method of the present invention based on a multi-station joint robot combined with a multi-layer shuttle car storage and separation method includes the following steps:

[0023] In the first step, the cigarettes in storage are identified by the cigarette storage system 1 to determine whether they are large-scale cigarettes;

[0024] The second step, when the cigarettes in the warehouse are large-scale cigarettes, they are sent to the stacking station of the multi-station joint robot 2.1 on the first floor through the wareho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com