Automatic cutting device of friction shoe of clutch

A technology of automatic cutting and friction tiles, applied in metal processing, etc., can solve problems such as low efficiency and affecting product quality, and achieve the effects of convenient use, good economic benefits, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

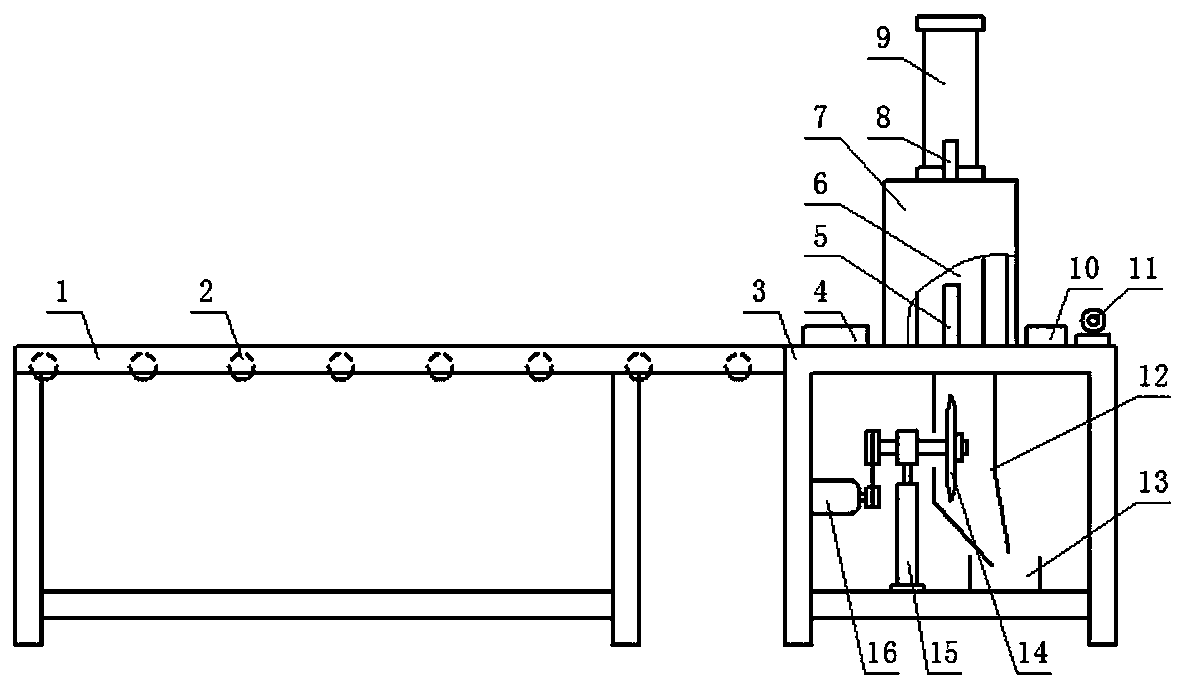

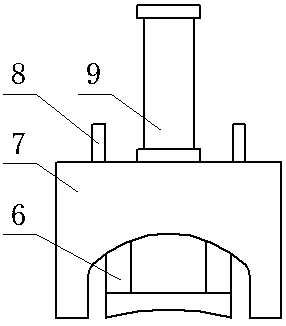

[0019] Example: see Figure 1-Figure 2 , in the picture, 1-feeding frame, 2-rotating roller, 3-frame, 4-front positioning block, 5-cutting seam, 6-briquetting block, 7-support, 8-guiding column, 9-lifting pressure cylinder , 10-rear guide block, 11-fixed length pressure cylinder, 12-protective cover, 13-swarf receiving hopper, 14-disc cutter, 15-jack pressure cylinder, 16-drive motor.

[0020] The clutch friction shoe automatic cutting device includes a feeding mechanism and a cutting mechanism, wherein: the feeding mechanism includes a feeding frame 1 and a rotating roller 2, and the rotating rollers 2 are evenly distributed on the upper end of the feeding frame 1, and an endless belt is arranged on the rotating roller 2, one of which The rotating roller 2 is connected with the rotating motor (not shown in the figure); the cutting mechanism includes a frame 3 and a lifting pressure cylinder 9, the upper end of the frame 3 is provided with a workbench, and a support 7 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com