A kind of preparation method of orange surfactant

A surfactant and active agent technology, applied in the field of preparation of orange surfactants, can solve the problem of few types of colored surfactants, and achieve the effect of convenient separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the present embodiment is as follows:

[0026] (1), preparation of intermediate lauryl alcohol polyoxyethylene ether (m=3) chloride

[0027] Add 0.0185mol polyoxyethylene lauryl ether (m=3) and 0.0369mol pyridine into a 100mL three-necked flask, stir well, then slowly add 0.0369mol thionyl chloride dropwise, and stir and react at 60-70°C for 10 hours; Stop the reaction, cool down, and stand still; the organic matter in the upper layer is neutralized to weak alkalinity with 15% sodium hydroxide solution, moved into a separatory funnel to separate the water layer, and the organic layer is washed with water for 5-6 times until there is no pungent smell. Pour the crude product into a single-necked round bottom flask, add 25mL of petroleum ether, and reflux at 60-90°C to remove water. Afterwards, the petroleum ether was distilled off to obtain a brown transparent liquid.

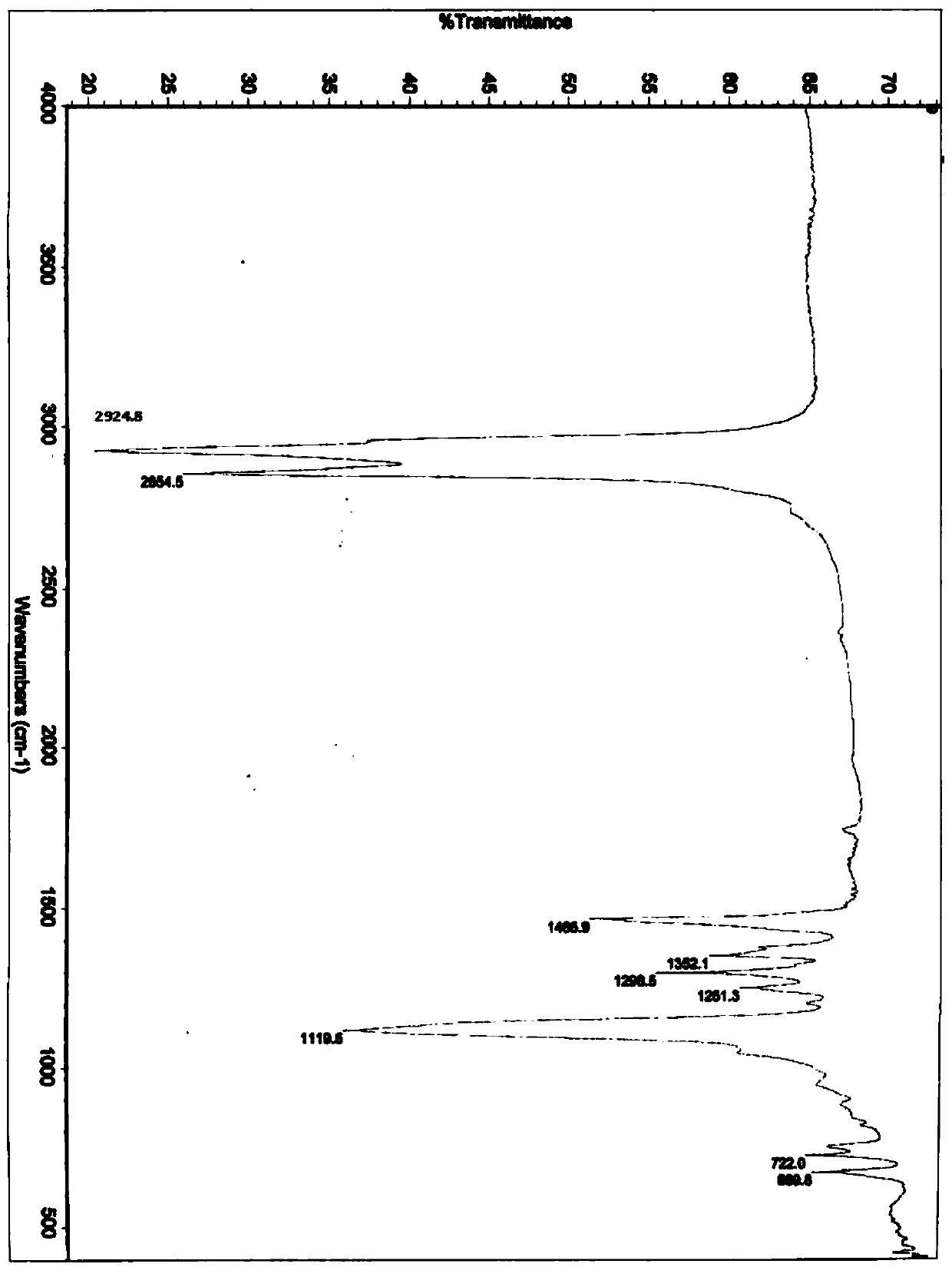

[0028] Depend on figure 1 It can be seen that 3000cm -1 There is no peak ...

Embodiment 2

[0033] The preparation method of the present embodiment is as follows:

[0034] (1) Preparation of intermediate octylphenol polyoxyethylene ether (m=10) chloride: add 0.0205mol octylphenol polyoxyethylene ether (m=10) and 0.0369mol pyridine into a 100mL three-neck flask, stir well Slowly add 0.0369mol thionyl chloride dropwise, and stir the reaction at 60-70°C for 12 hours. Stop the reaction, cool down, and let stand. The organic matter in the upper layer was neutralized to weak alkalinity with 15% sodium hydroxide solution, moved into a separatory funnel to separate the water layer, and the organic layer was washed with water for 5-6 times until there was no pungent smell.

[0035] The crude product was poured into a single-necked round bottom flask, and 35 mL of petroleum ether (60-90° C.) was added to reflux to remove water. Afterwards, it was concentrated by rotation to obtain a brown transparent liquid.

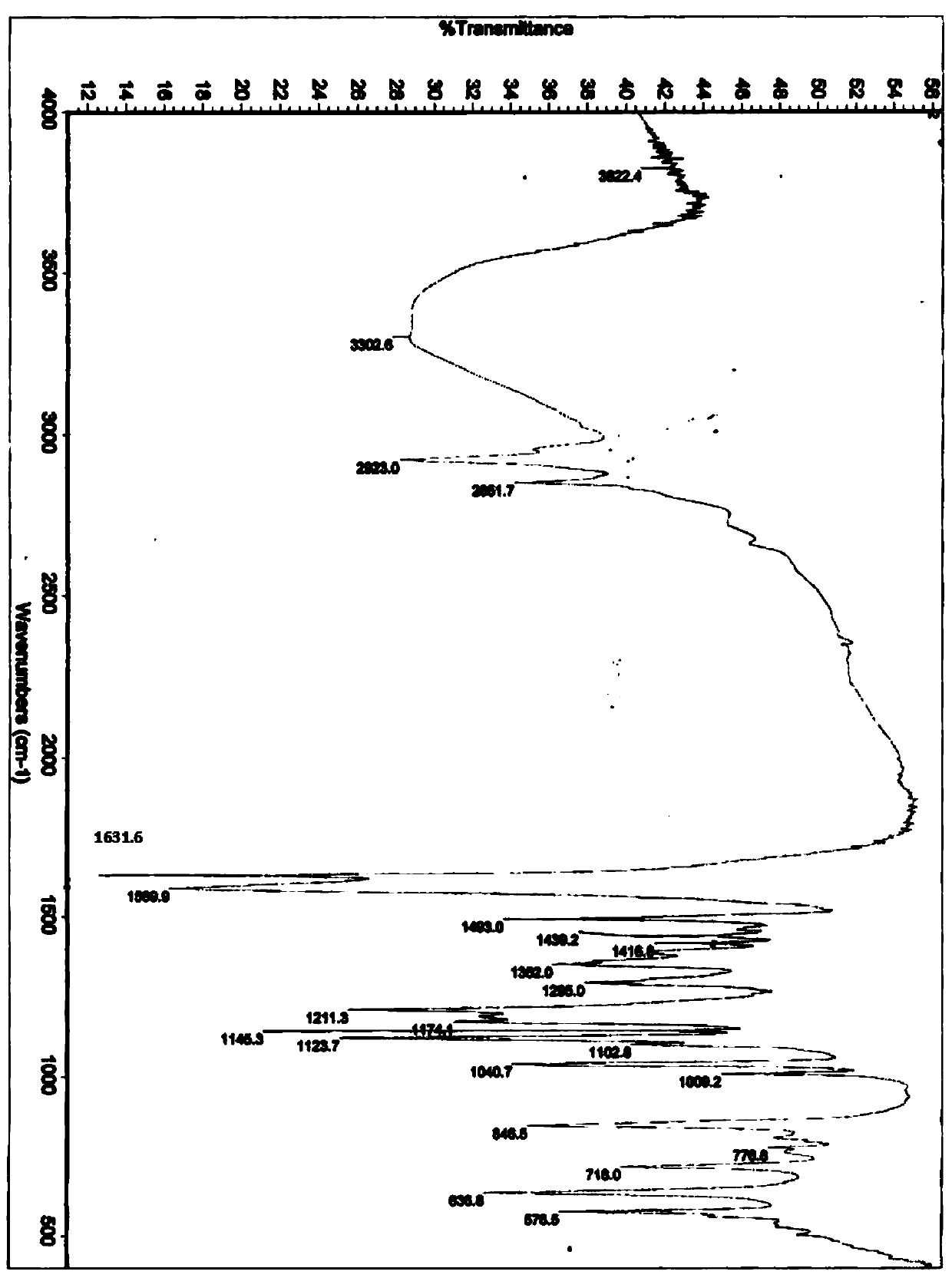

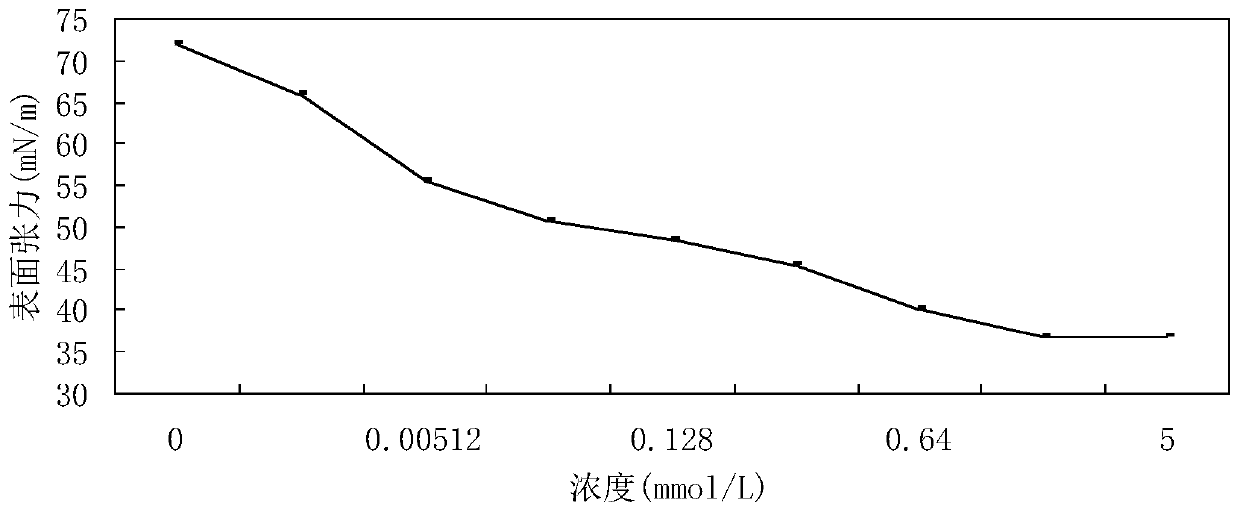

[0036] (2) Preparation of octylphenol polyoxyethylene ether (m=1...

Embodiment 3

[0038] The preparation method of the present embodiment is as follows:

[0039] (1) Preparation of intermediate nonylphenol polyoxyethylene ether (m=5) chloride: add 0.0195mol nonylphenol polyoxyethylene ether (m=5) and 0.0369mol pyridine into a 100mL three-neck flask, stir well Slowly add 0.035mol thionyl chloride dropwise, and stir the reaction at 60-70°C for 3.5 hours. Stop the reaction, cool down, and let stand. The organic matter in the upper layer was neutralized to weak alkalinity with 15% sodium hydroxide solution, moved into a separatory funnel to separate the water layer, and the organic layer was washed with water for 5-6 times until there was no pungent smell.

[0040] Pour the crude product into a single-necked round-bottomed flask, add 30ml appropriate amount of petroleum ether (60-90°C) and reflux to remove water. Afterwards, the petroleum ether was distilled off to obtain a brown transparent liquid.

[0041] (2) Preparation of nonylphenol polyoxyethylene eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com