Kitchen sink dish-washing machine

A technology for kitchen sinks and dishwashers, applied in the field of household kitchen utensils, can solve the problems of flushing, inability to achieve dishes, and insufficient cleaning of dishes, and achieve the effect of improving the spray effect and increasing the spray area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

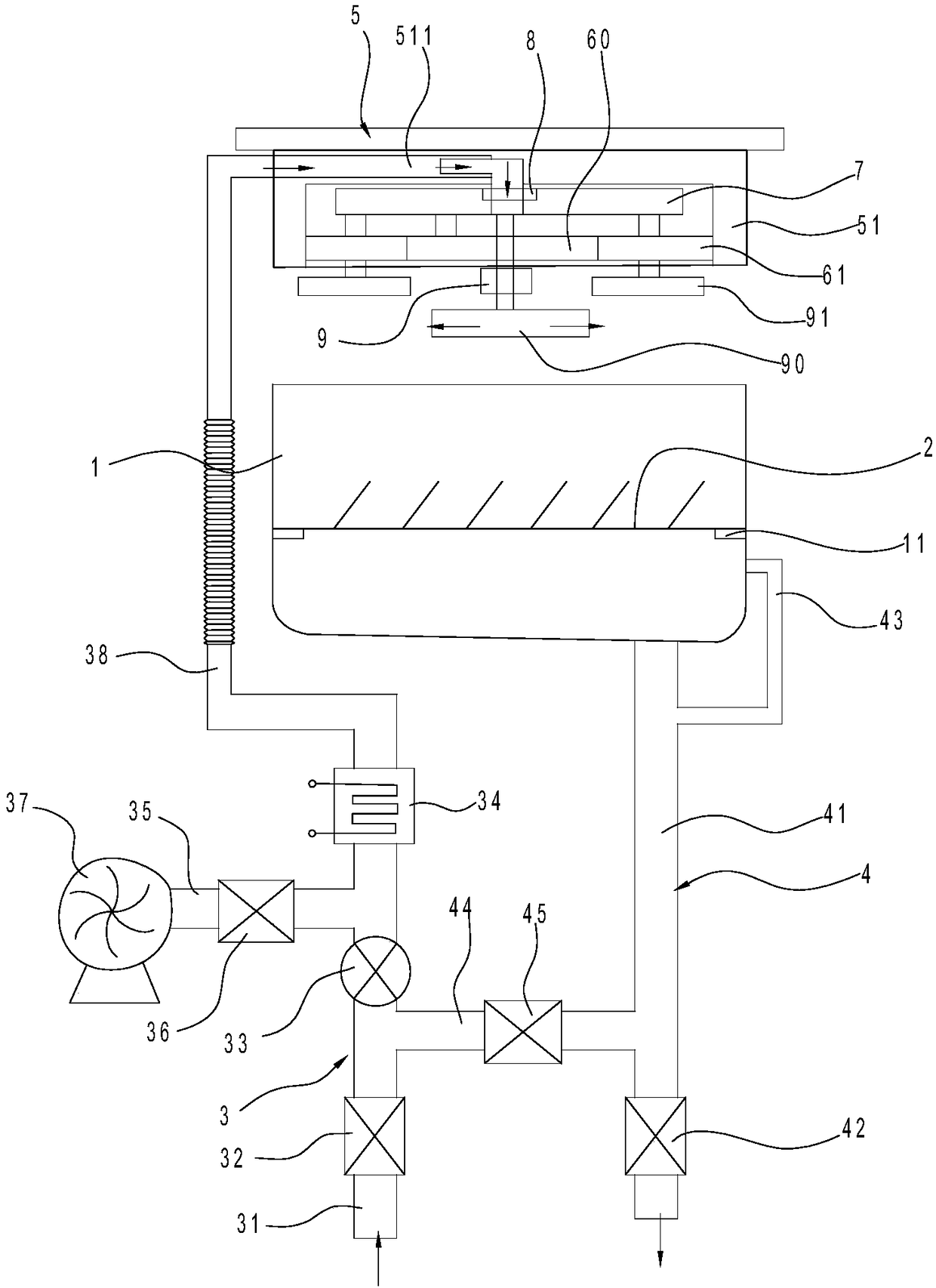

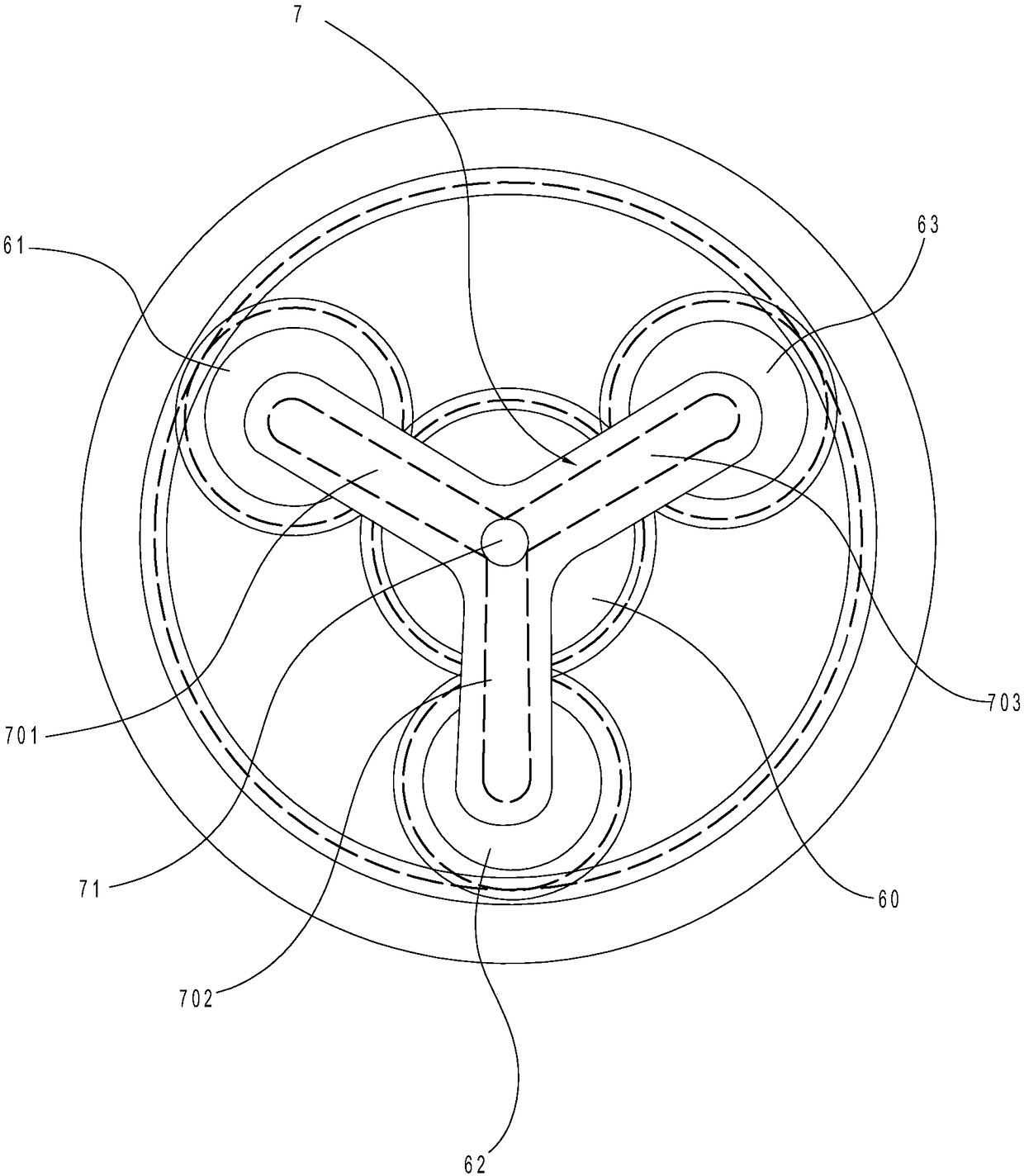

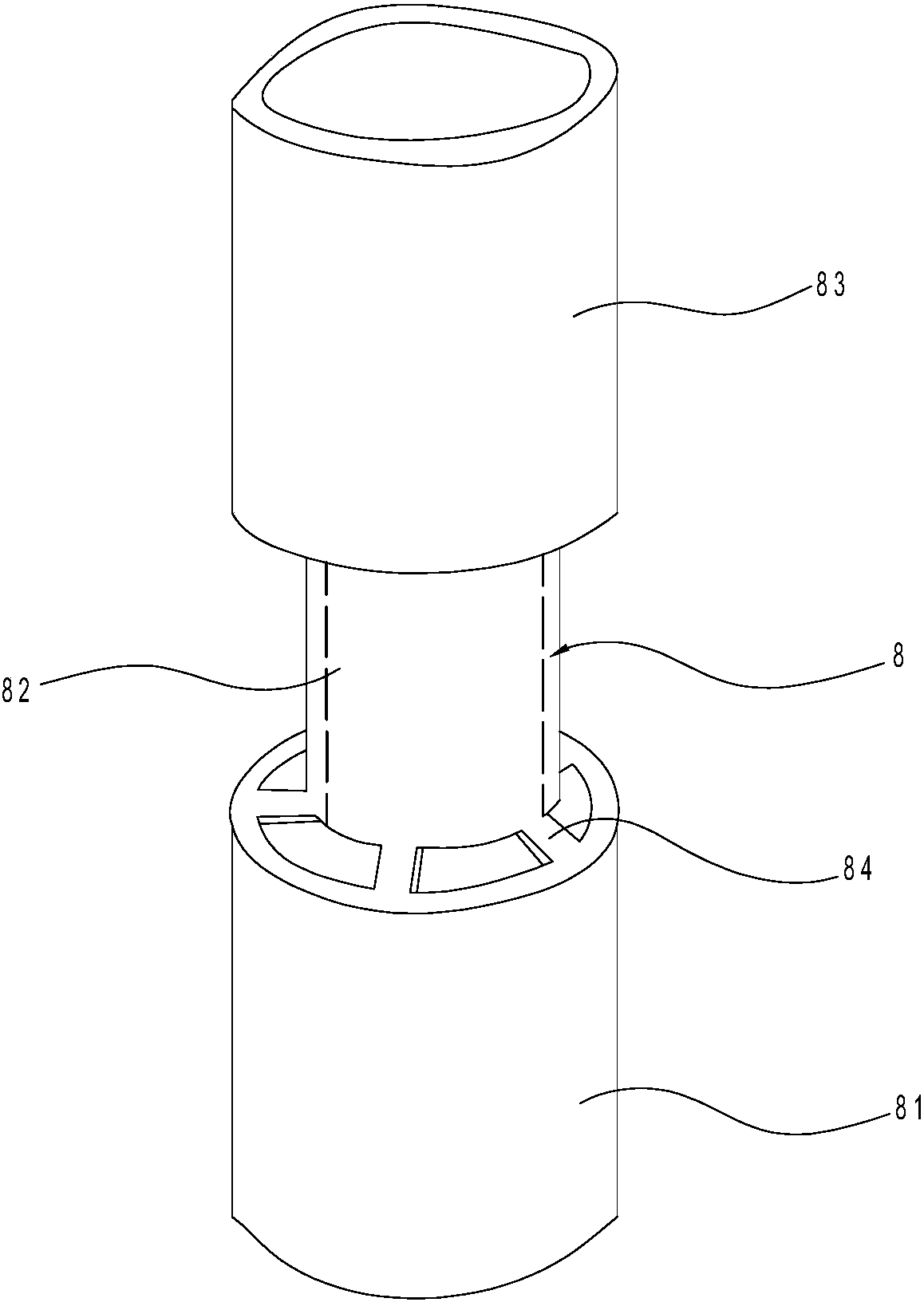

[0018] Such as Figures 1 to 3 As shown, the kitchen sink dishwasher in this implementation includes a tank body 1, a cover plate 5, a dishwashing rack 2, a spray system, a hollow motor 9, a sun gear 60, a first planetary wheel 61, and a second planetary wheel 62 , the third planetary wheel 63, the planetary carrier 7, the flow divider 8, the main spray arm 90, the first spray arm 91, the second spray arm, the third spray arm, and the water level detector.

[0019] Wherein, the cover plate 5 covers the tank body 1, the dish washing rack 2 is arranged in the tank body 1, and a water level detector is arranged in the tank body 1, specifically, a support ring 11 is extended on the inner side wall of the tank body 1 , the bottom of the dishwashing rack 2 is placed on the support ring 11, thereby facilitating the placement and removal of the dishw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com