Modified cellulose fine fibers and method for producing same

A technology for modifying cellulose and its manufacturing method, which is applied in the field of modifying cellulose microfibers and its manufacturing, which can solve the problems of low dispersibility of organic media, heavy environmental burden, and difficult drainage treatment, so as to improve affinity and reduce damage Less, improve the effect of disintegration and modification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] In the preparation method of the reactive fiber dissolving liquid, the above-mentioned catalyst, the above-mentioned monocarboxylic anhydride, and the above-mentioned solvent can be mixed in advance by stirring or the like, and the monocarboxylic anhydride can be uniformly dissolved in the above-mentioned catalyst and the above-mentioned solvent.

[0093] Since the obtained reactive fibrinolysis solution has a high impregnation property to cellulose, by adding and mixing cellulose to the reactive fiber solution, the reactive solution penetrates between the microfibrils, and the microfibrils present in the By modifying the hydroxyl groups on the surface of the fibrils, the modification and fibrillation of cellulose can be performed simultaneously.

[0094] In detail, the chemical defibrating method may be a method in which cellulose is mixed in a reactive defibrating solution and left to stand for more than 1 hour to perform esterification. After mixing, the cellulose can...

Embodiment 1

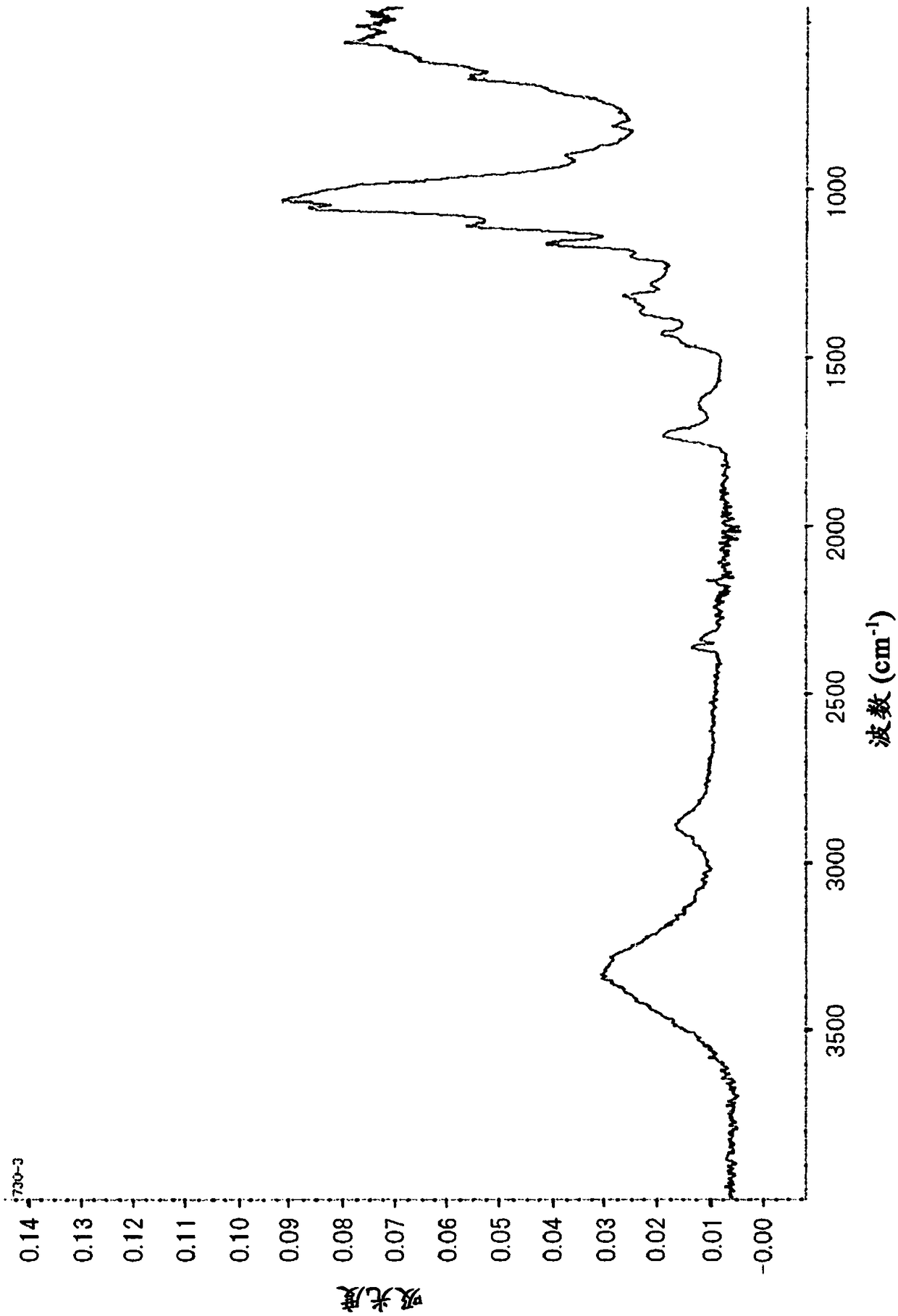

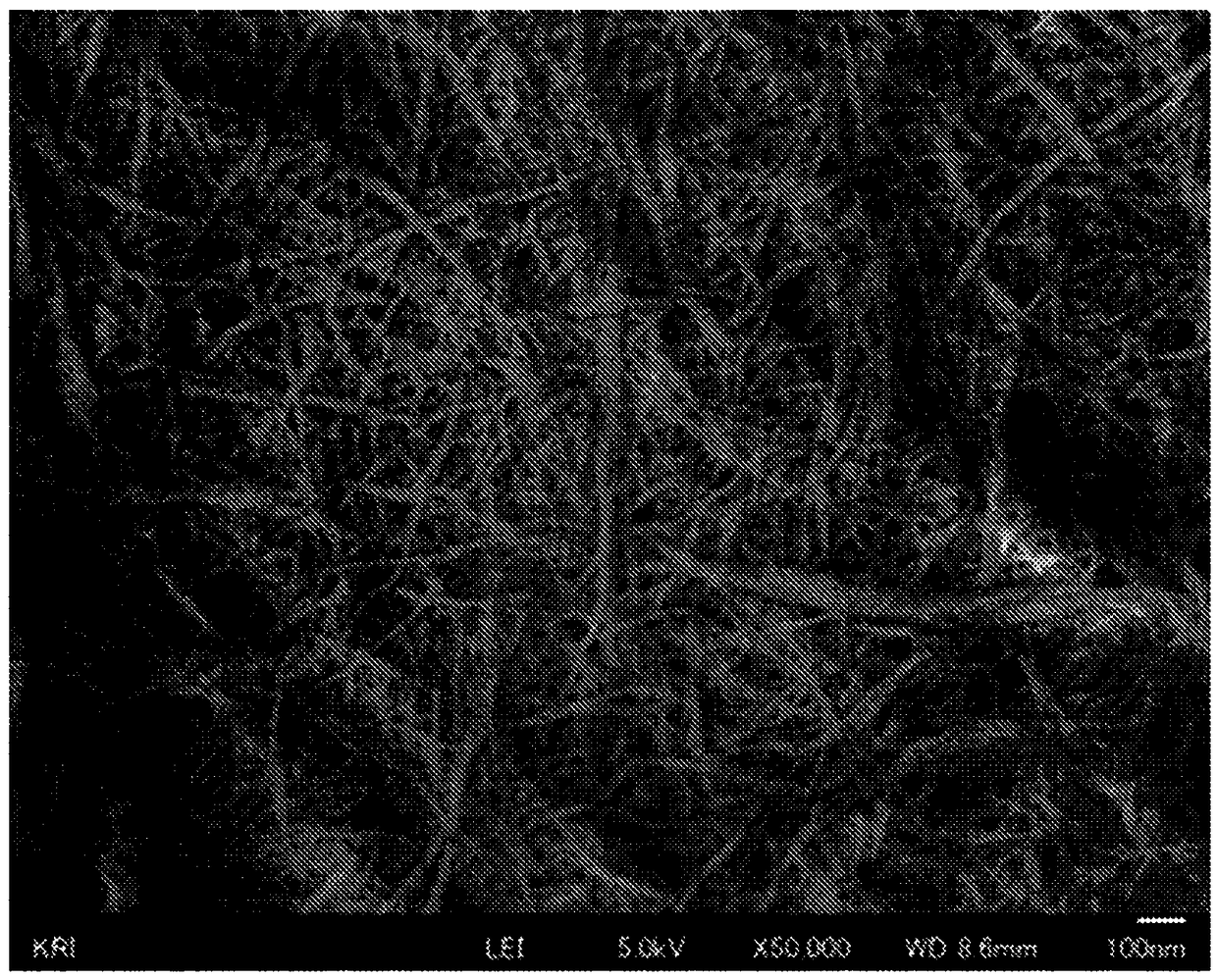

[0148] Put 3 g of pyridine, 7 g of DMSO, and 1.3 g of propionic anhydride into a 20 ml sample bottle, and stir with a stirrer until the mixture is uniformly mixed. Next, after adding 0.3 g of cellulose pulp and stirring for another 24 hours, pyridine, DMSO, and residual propionic anhydride were removed by washing with a mixed solution of acetone and water. The solid content was recovered, and the average degree of substitution was measured for the obtained modified cellulose fine fibers, the modified functional group was confirmed by FT-IR analysis, the shape was observed by scanning electron microscope (SEM), the crystallinity was measured by XRD analysis, and the degree of fiber disintegration and Solvent dispersibility was evaluated. The results of FT-IR analysis are shown in figure 1 , the SEM photographs are shown in figure 2 . As a result of SEM observation, the average fiber diameter of the fibers was 30 nm, and the average fiber length was 9.5 μm. It should be not...

Embodiment 2

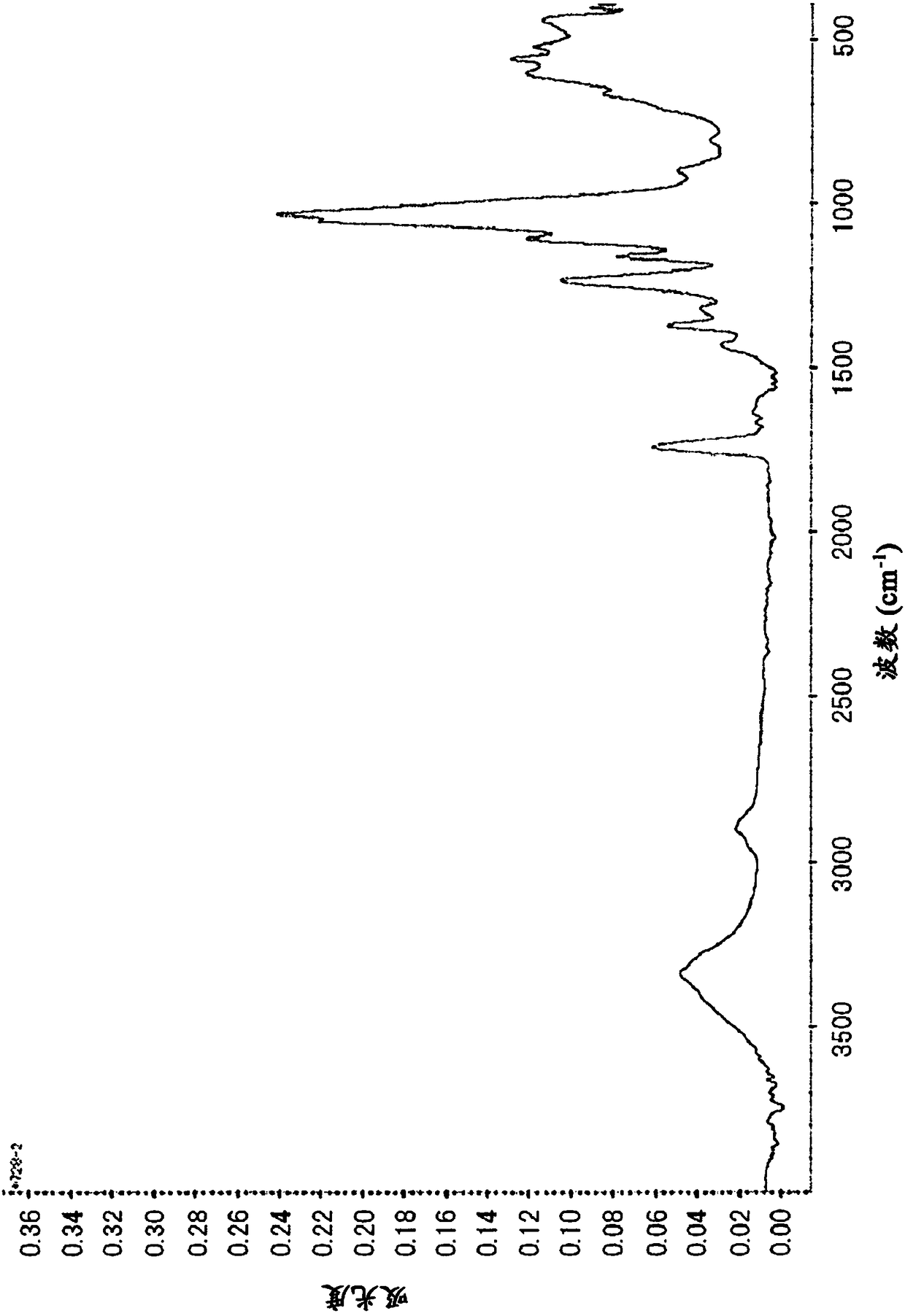

[0150] 3 g of pyridine, 7 g of DMAc, and 1 g of acetic anhydride were placed in a 20 ml sample bottle, and the same procedure as in Example 1 was carried out to obtain modified cellulose fine fibers. The obtained modified cellulose fine fibers were evaluated in the same manner as in Example 1. The results of FT-IR analysis are shown in image 3 , the SEM photographs are shown in Figure 4 . As a result of SEM observation, the average fiber diameter of the fibers was 93 nm, and the average fiber length was 12.3 μm. It should be noted that the saturated absorption rate of the pulp in the defibrating solution was 28 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com