Method for characterizing ion-exchanged chemically strengthened glasses containing lithium

A technology of strengthening glass and chemistry, which is applied in the fields of material analysis through electromagnetic means, measurement of the change force of optical properties of the material when it is stressed, and scientific instruments, etc. It can solve the difficulties in the manufacture of chemically strengthened Li-containing glass, which cannot be distributed Characterization, lack of glass quality control and other problems, to achieve the effect of improving quality control, improving precision, and avoiding the influence of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Various embodiments of the disclosure are described in detail below, examples of which are illustrated in the accompanying drawings. Wherever possible, the same or similar reference numbers and symbols will be used throughout the drawings to refer to the same or similar parts. The drawings are not necessarily to scale and those skilled in the art will appreciate that the drawings are simplified to show key aspects of the invention.

[0045] The following claims are incorporated into and constitute a part of this Detailed Description.

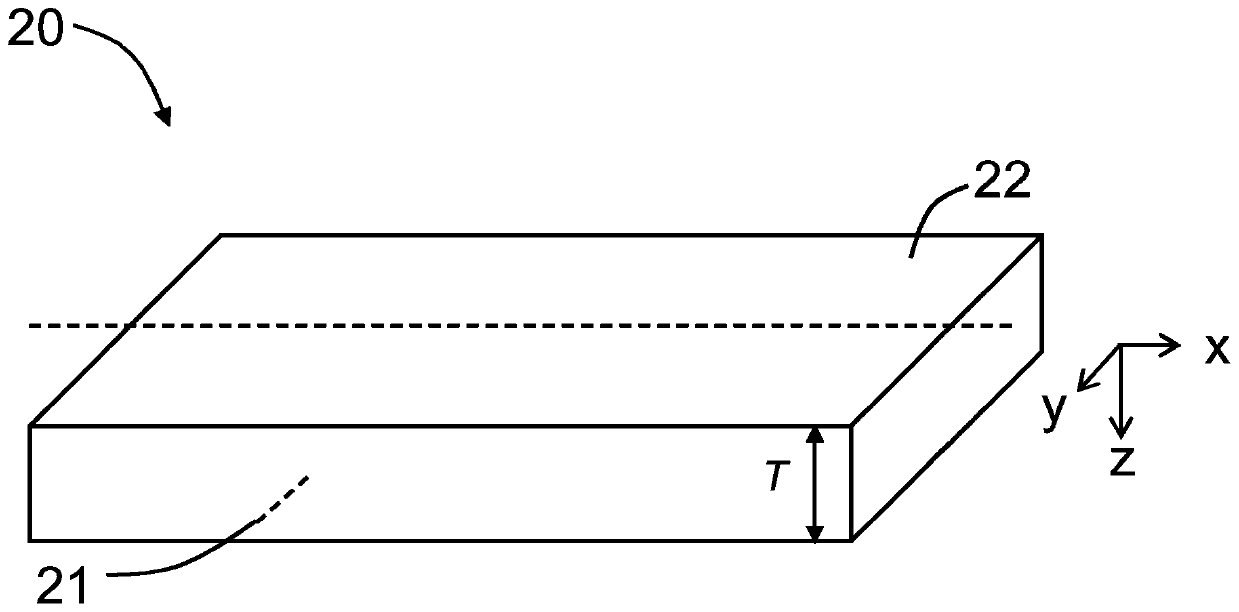

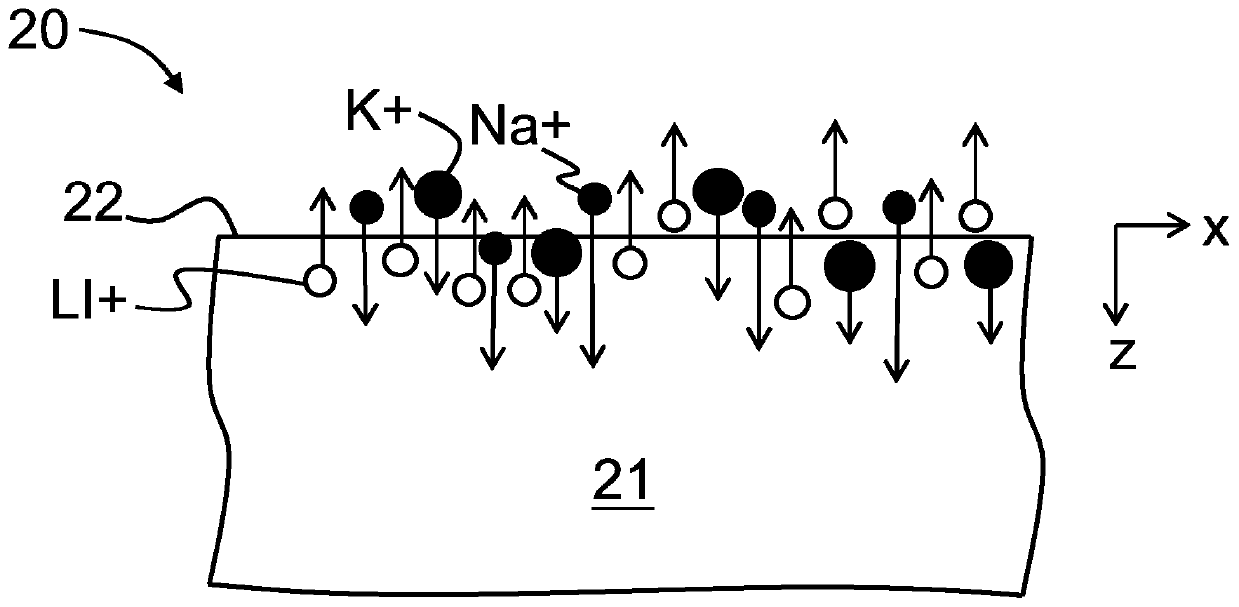

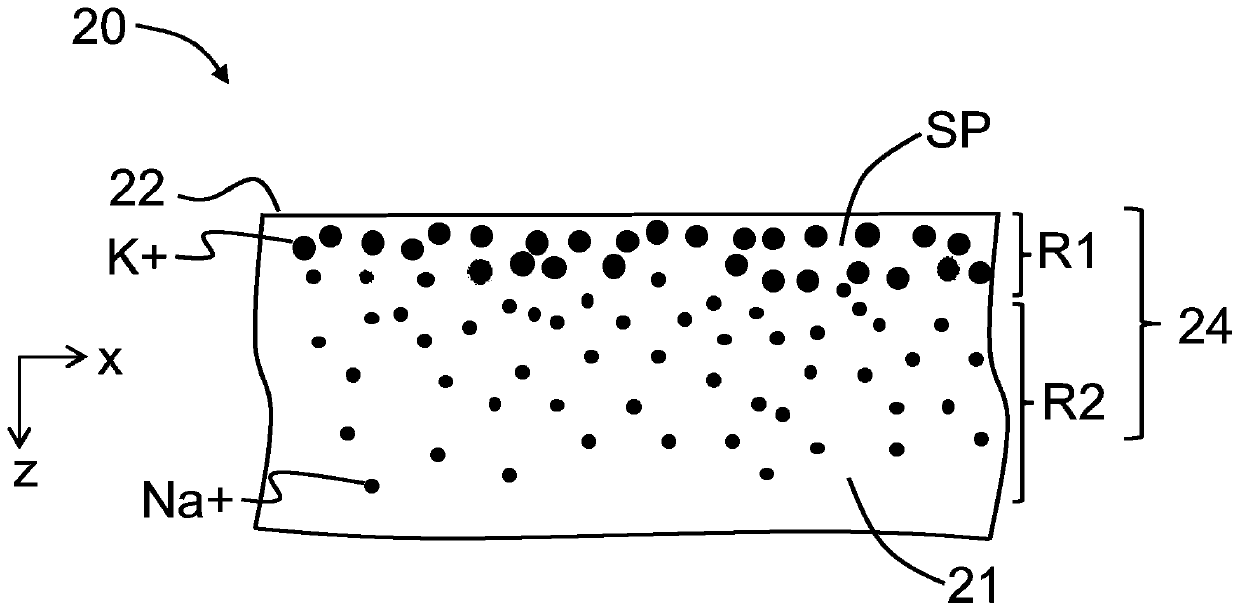

[0046] Figure 1A is an enlarged view of an exemplary glass substrate in the form of a planar ion exchange substrate 20 having a body 21 and a (top) surface 22, wherein the body has a substrate (bulk) refractive index n s , surface refractive index n 0 and the thickness T in the z direction. Figure 1B is a close-up view of a cross-section of ion exchange substrate 20 taken along the y-z plane, showing an exemplary double ion exchange ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com