Device and method for additive manufacturing

A technology of additive manufacturing and equipment, applied in the field of additive manufacturing equipment, can solve the problem of different actual temperature and preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The drawings and description are only examples of the invention.

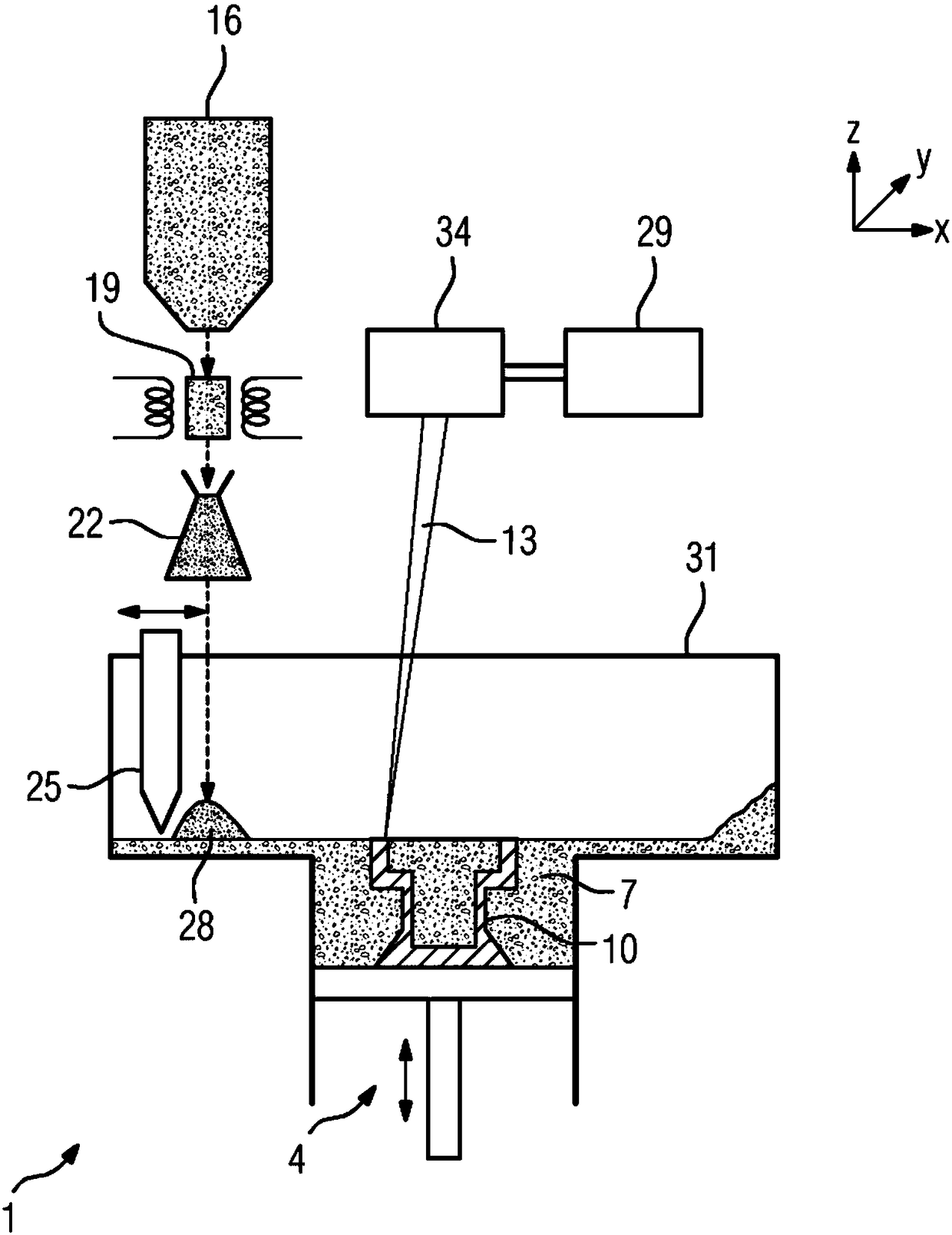

[0028] The device 1 has, as in the prior art, a movable platform 4 on which a powder bed 7 is formed. The platform 4 is movable in a downward direction (z-direction) in order to be able to apply a new layer of powder. The component 10 to be produced is present or produced in the powder bed 7 .

[0029] In the process chamber 31 , the powder is selectively densified, ie sintered or melted, layer by layer by means of an energy beam 13 , in particular the laser beam 13 of a laser 29 , and a corresponding scanner 34 .

[0030] By means of the brush 25 , as in the prior art, the powder 28 is applied as a new layer, after which the platform 4 is lowered by a certain value.

[0031] According to the invention, however, the freshly applied powder 28 is preheated. This can be done in different ways and methods.

[0032] There can be further heating devices which preheat the entire powder storage 16 according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com