Preparation method and applications of graphene aerogel

A graphene aerogel, enol gel technology, applied in graphene, chemical instruments and methods, other chemical processes, etc., can solve the problem of graphene aerogel materials with large specific surface area, large adsorption capacity, and inability to achieve heavy metals Ion in-situ adsorption-on-line desorption and other problems, to achieve the effect of good conductivity, large adsorption capacity, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 prepares graphene airgel

[0030] (1) Take 50 mL of graphene oxide aqueous solution prepared by the Hummers method with a concentration of 5 mg / L, add it to a 50 mL centrifuge tube, centrifuge at 12000 rpm for 30 min, remove the supernatant after each centrifugation, and add 50 mL of absolute ethanol to prepare graphite Enol solution, the graphene alcohol gel concentration formed is 5mg / mL;

[0031] The above-mentioned Hummers method can be found in literature L. Zhang, J. Liang, Y. Huang, Y. Ma, Y. Wang, Y. Chen, Carbon 2009, 47, 3365.

[0032] In the specific implementation, the centrifugation time and frequency of the graphene oxide aqueous solution and the amount of absolute ethanol can be controlled according to the actual situation, as long as the concentration of the graphene alcohol gel finally obtained is within the range of 0.2-10.0mg / mL purpose of the invention.

[0033] (2) Pour the graphene alcohol gel into the hydrothermal reaction kettle, a...

Embodiment 2

[0039] The graphene airgel photograph that present embodiment obtains is as figure 1 As shown, its height: 3~4cm, diameter 2~3cm, pores 1nm~50μm, specific surface area about 1800~2200m 2 / g, density 1~5mg / cm 3 . Embodiment 2 heavy metal ion adsorption-desorption test

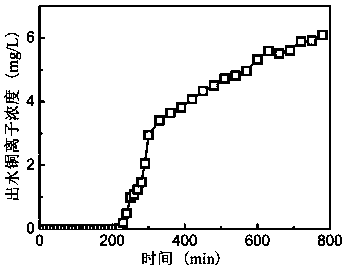

[0040] Preparation of simulated heavy metal ion solution: Weigh 15 mg of anhydrous copper sulfate, dissolve it in 1L of ultrapure water, and adjust the pH of the solution to pH=5 after it is completely dissolved; 2+ The concentration is 6mg / L.

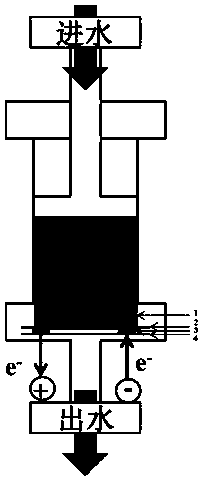

[0041] The adsorption-desorption test procedure is as follows: figure 2 Shown:

[0042] (a) Adsorption: the graphene airgel obtained in Example 1 is assembled in a filter-type column electrode reaction system as an anode: the graphene airgel is packed into a column filter device, and the titanium sheet is tightly pressed on the graphite The aerogel is used as a connection to connect to the power supply; another titanium sheet is used as the cathode to form the ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com