Image sensor and forming method thereof

An image sensor and optical filter technology, which is applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., to avoid crosstalk and make full use of light transmission area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

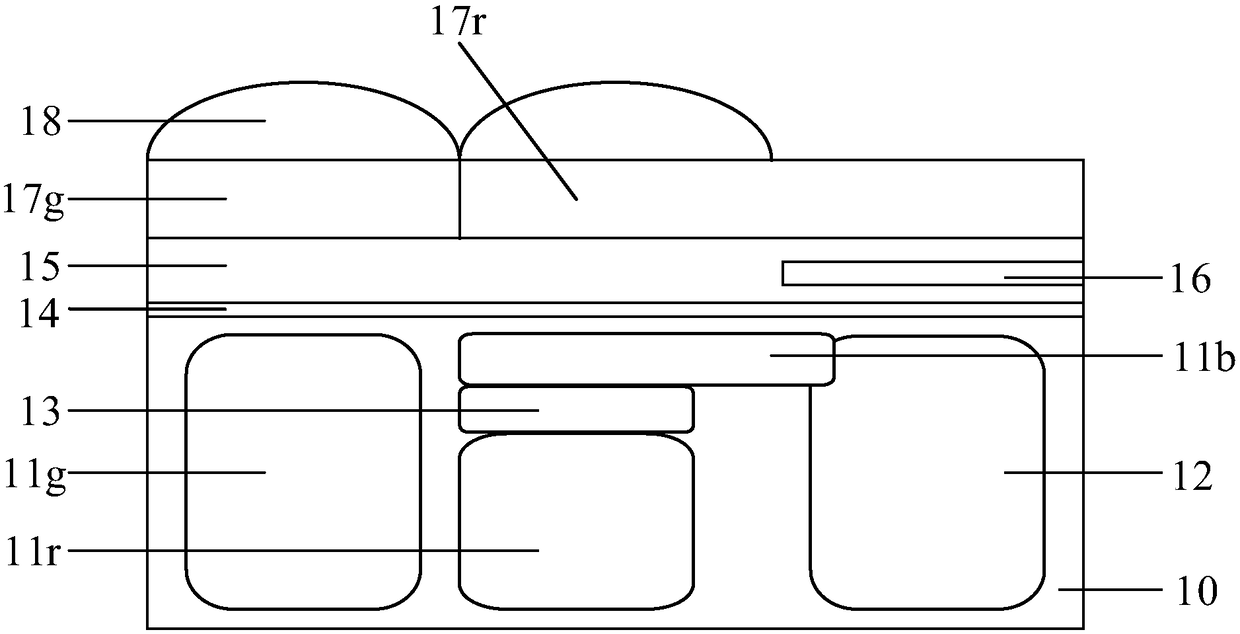

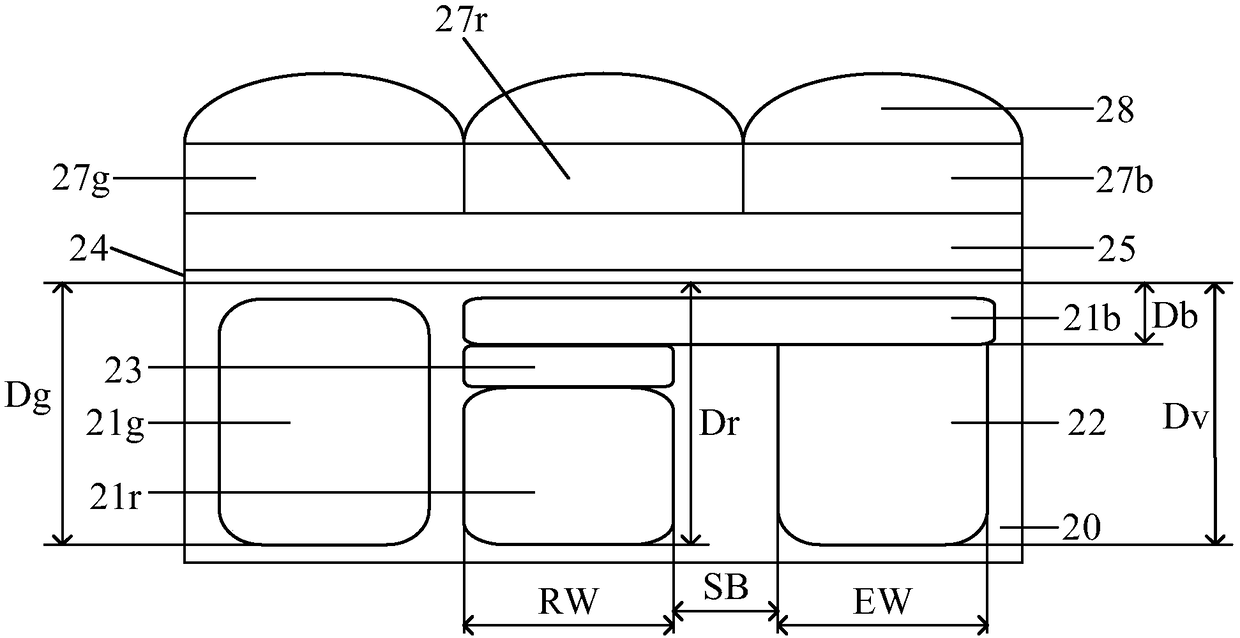

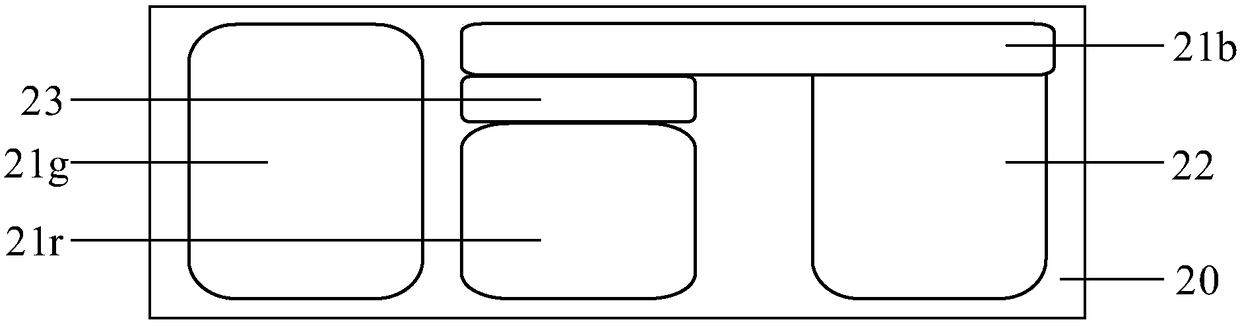

[0036] In the prior art, since a metal barrier layer is added on the vertical charge transfer layer to reflect the light above the vertical charge transfer layer, the crosstalk of light to the vertical charge transfer layer is reduced, but the existence of the metal barrier layer makes the above The light-transmitting area is wasted, and the filling rate of the image sensor is reduced, thereby reducing the performance of the image sensor.

[0037] In response to the above problems, the technical solution of the present invention provides a new type of image sensor based on a vertical pixel structure, which expands the area of the photodiode that absorbs blue light to cover the vertical charge transfer layer, thus avoiding the crosstalk of light to the vertical charge transfer layer, At the same time, the metal light-blocking structure on the vertical charge transfer layer is removed to increase the light-transmitting area, so as to realize a high-performance image sensor.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com