Method and device for testing friction pair material pair adhesion coefficient

A technology of adhesion coefficient and testing equipment, which is applied in the direction of measuring equipment, analyzing materials, adopting mechanical equipment, etc., and can solve the problems of moving parts stuck, motion failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

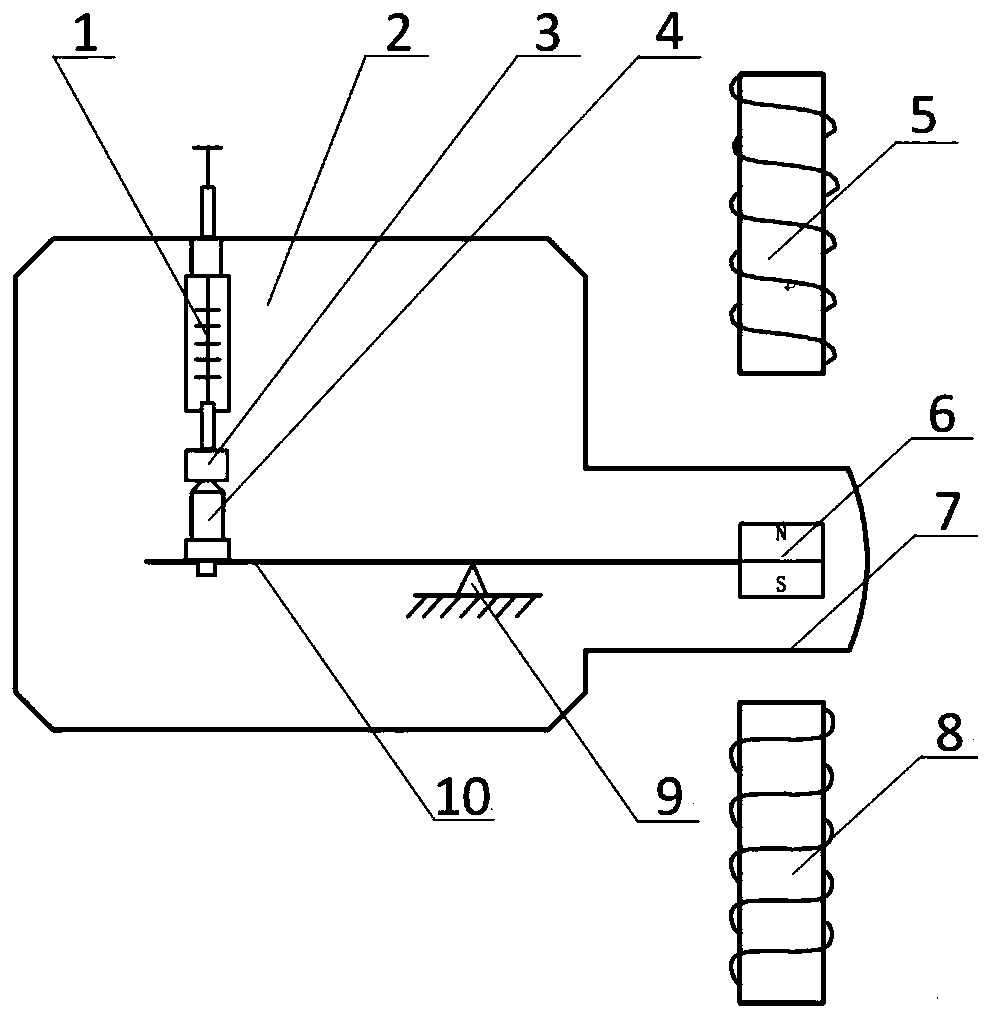

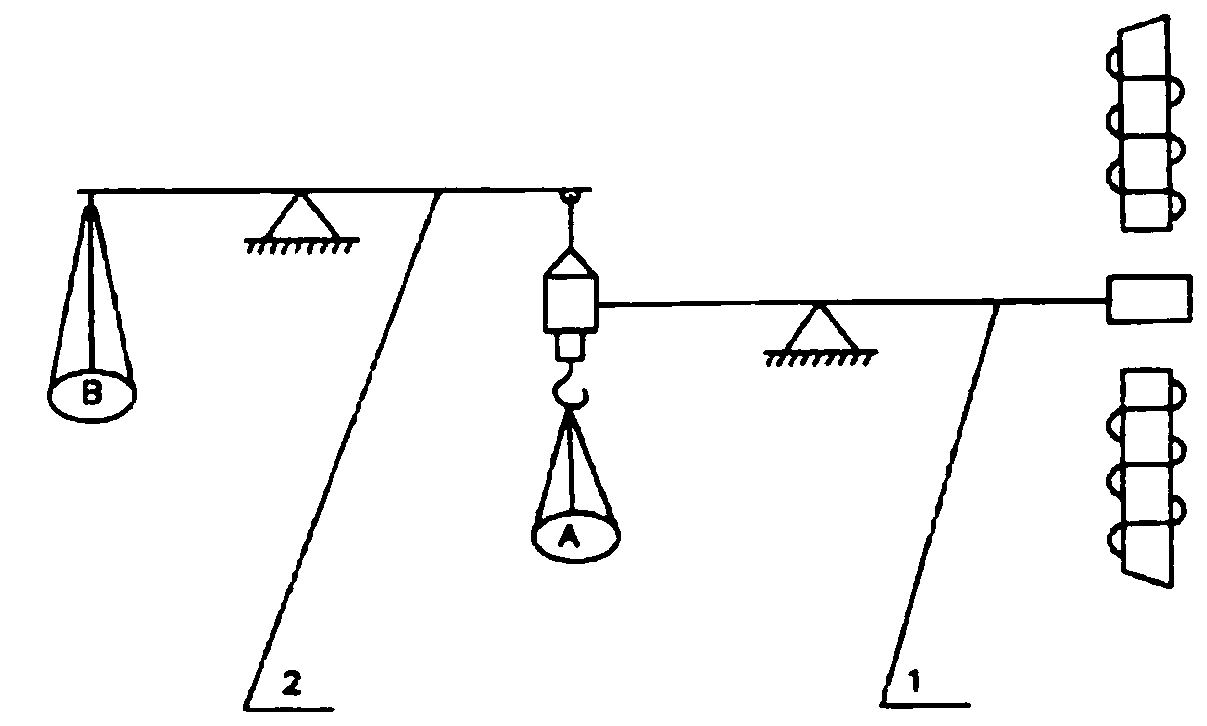

[0032] The specific implementation of this test method will be described in detail below with reference to the accompanying drawings.

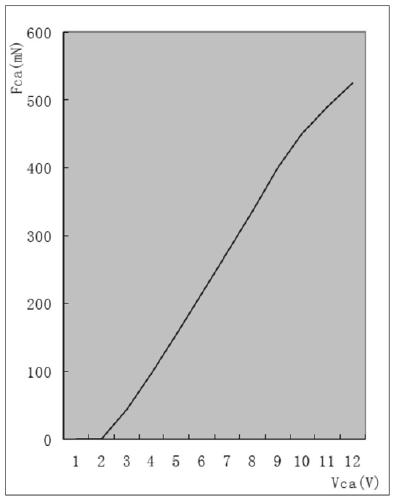

[0033] like figure 1 As shown, the test device of the present invention includes a vacuum chamber, a material paired upper sample clamp that can be adjusted up and down, a balance lever for loading and unloading the test load, an upper and lower electromagnetic coil for loading and unloading, and a magnetically permeable glass sealing cylinder; wherein,

[0034] The upper end of the material pairing upper sample fixture that can be adjusted up and down is connected to the vacuum chamber to achieve vacuum sealing. The lower end (the end face exposed to the vacuum chamber) is fixed with a screw hole structure to fix the upper sample to be tested, and a threaded rod is installed at the middle axis of the bellows, outside the vacuum chamber. The lower end of the bellows can be moved up and down by rotating the matching nut without affecting the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com