Method for mounting large-span arch bridge tie bars

A technology for long-span arch bridges and tie rods, which is applied to arch bridges, erecting/assembling bridges, bridges, etc., can solve the problems of long-time occupation of cable cranes, many manual aerial operations, and difficult communication, and reduce aerial operations and manual operations. , to meet the effect of rapid construction, convenient construction and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] The invention provides a method for installing tie rods of a long-span arch bridge, the method comprising the following steps:

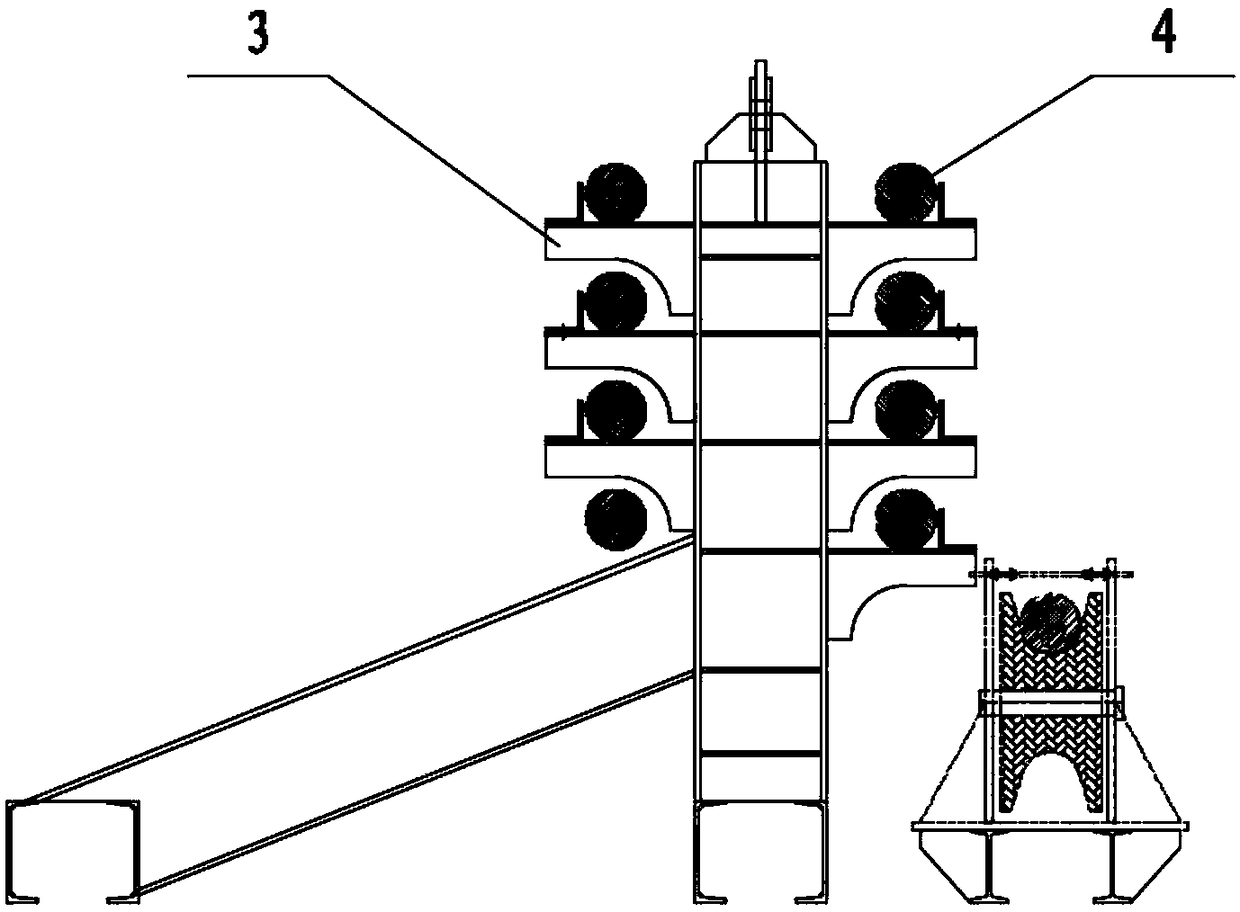

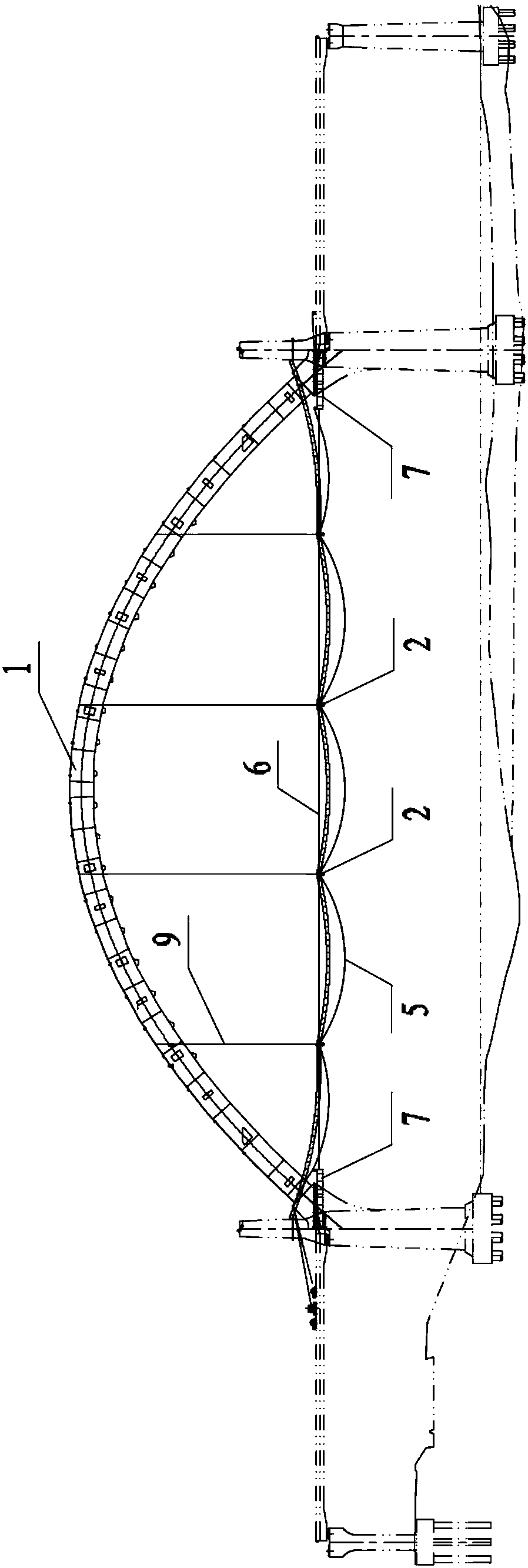

[0036] S1. See Figure 1 to Figure 3 As shown, a plurality of brackets 2 are suspended at intervals on the arch rib 1, and at least one support frame 3 is arranged on each bracket 2, and a plurality of spaces for receiving tie rods 4 are provided on the support frame 3, and on both sides of the arch bridge Windlass and traction rope 5 are installed at the end;

[0037] Specifically, each support 2 is suspended on the ring of the arch rib 1 through a wire rope 9, and the support 2 in the present invention is a Bailey beam support. In addition, a reciprocating traction system can be formed after installing hoists and traction cables 5 at both ends of the arch bridge.

[0038] The present invention also utilizes the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com