Production method of high-performance ultrathin electrolytic copper foil for lithium-ion batteries

A lithium-ion battery and production method technology, applied in the electrolysis process, electroforming and other directions, can solve the problems of difficulty in production, inclusion of organic substances, reducing the intrinsic properties of copper foil, etc., to prevent fracture, prolong service life, and achieve high tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

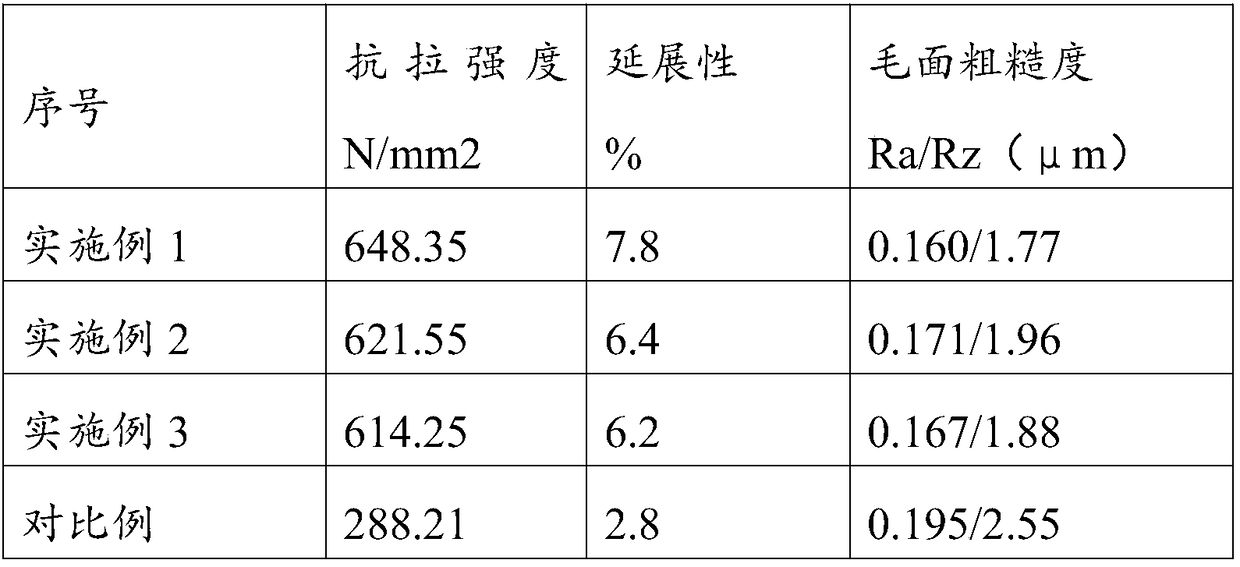

Examples

Embodiment 1

[0021] A method for producing ultra-thin electrolytic copper foil for high-performance lithium-ion batteries, comprising the steps of:

[0022] 1) Control the copper sulfate content of the electrolyte in the high level tank to be 340-360g / L, and the sulfuric acid content to be 125-135g / L;

[0023] 2) Continuously add collagen and SPS to the head tank, control the content of collagen in the plating solution to be 0.3g / KAh, and the content of SPS to be 0.15g / KAh, and flow into the electrolytic tank after fully stirring;

[0024] 3) Electrodeposition: adjust the temperature of the plating solution to 50°C, use a high-frequency pulse power supply at a current density of 60A / dm 2 Electrodeposit the copper ions in the plating solution between the cathode and anode plates, control the frequency of the high-frequency pulse power supply to 70Hz, and adopt a duty ratio of 0.8 to prepare an ultra-thin film with a thickness of 6 microns on the surface of the titanium cathode roller. Elec...

Embodiment 2

[0026] A method for producing ultra-thin electrolytic copper foil for high-performance lithium-ion batteries, comprising the steps of:

[0027] 1) Control the copper sulfate content of the electrolyte in the high level tank to be 310-330g / L, and the sulfuric acid content to be 120-130g / L;

[0028] 2) Continuously add collagen and SPS to the head tank, control the content of collagen in the plating solution to be 0.05g / KAh, and the content of SPS to be 0.5g / KAh, and flow into the electrolytic tank after fully stirring;

[0029] 3) Electrodeposition: adjust the temperature of the plating solution to 52°C, use a high-frequency pulse power supply at a current density of 70A / dm 2 Electrodeposit the copper ions in the plating solution between the cathode and anode plates, control the frequency of the high-frequency pulse power supply to 50Hz, and adopt a duty ratio of 0.9 to prepare an ultra-thin film with a thickness of 6 microns on the surface of the titanium cathode roller. Elec...

Embodiment 3

[0031] A method for producing ultra-thin electrolytic copper foil for high-performance lithium-ion batteries, comprising the steps of:

[0032] 1) Control the copper sulfate content of the electrolyte in the high level tank to be 360-380g / L, and the sulfuric acid content to be 130-140g / L;

[0033] 2) Continuously add collagen and SPS to the head tank, control the content of collagen in the plating solution to be 0.8g / KAh, and the content of SPS to be 0.05g / KAh, and flow into the electrolytic tank after fully stirring;

[0034] 3) Electrodeposition: adjust the temperature of the plating solution to 55°C, use a high-frequency pulse power supply to conduct electrodeposition on the copper ions in the plating solution between the cathode and anode plates at a current density of 40A / dm2, and control the high-frequency pulse power supply The frequency is 100 Hz, and the duty ratio of 0.75 is adopted to prepare an ultra-thin electrolytic copper foil with a thickness of 6 microns on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com