Cavitation water jet impact strengthening device

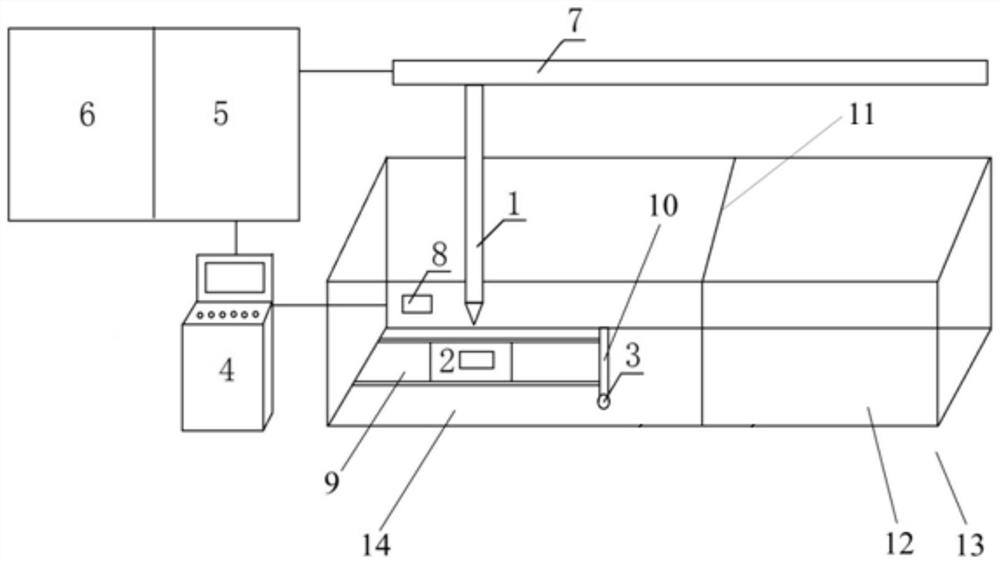

A technology of impact strengthening and water jet, which is applied in the field of cavitation water jet impact strengthening device and surface impact strengthening device, which can solve the problems of large space occupation, lack of effective monitoring of the treatment process, and inability to adjust the water level of the sample pool and the reservoir in association. , to achieve the effect of easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Exemplary embodiments of the present invention are described in detail below. In addition, in the following detailed description, for purposes of explanation, numerous specific details are set forth in order to provide a comprehensive understanding of the embodiments of the present disclosure. It may be evident, however, that one or more embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in diagrammatic form to simplify the drawings.

[0026] In the present invention, the cavitation water jet impact strengthening is to spray the high-pressure water jet carrying huge energy onto the surface of the metal material in a specific way, so that the surface layer of the material undergoes plastic deformation at the recrystallization temperature and presents an ideal structure. Structure (that is, tissue strengthening) and residual stress distribution (that is, stress strengthening), so as to achieve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com