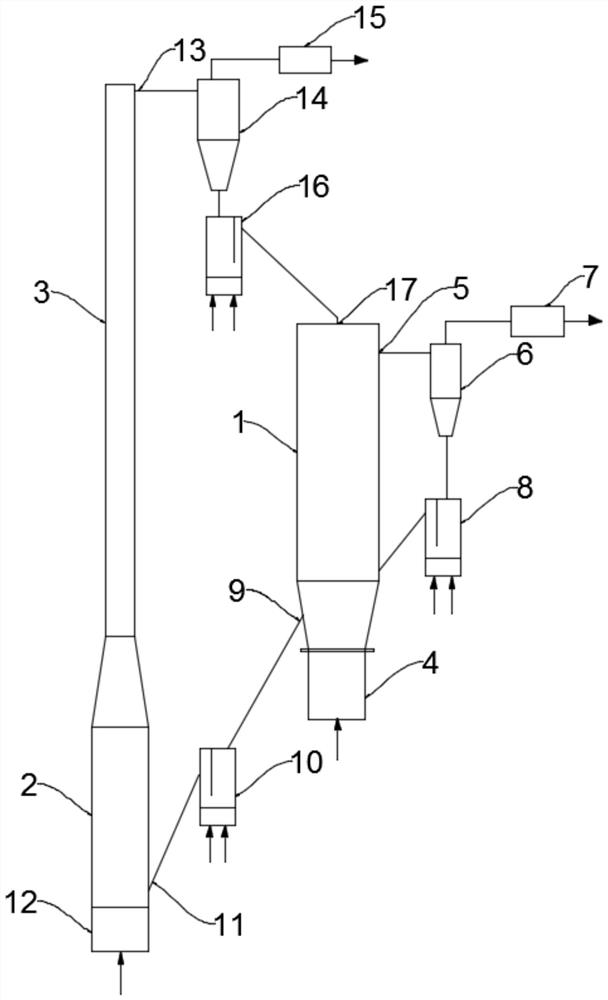

Device and method for autothermal production of high-purity hydrogen by catalytic cracking of methane

A methane catalysis and methane gas technology, applied in chemical instruments and methods, hydrogen production, hydrogen/synthesis gas production, etc., can solve the problems of low hydrogen concentration, high operating cost, low methane cracking conversion rate, etc., to save production Cost, reduced energy consumption, simple installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] This embodiment also provides a method for the autothermal production of high-purity hydrogen by catalytic cracking of methane. The method uses an activated carbon catalyst and the device in Example 1. The specific steps of the method are the same as in Example 1. The reaction conditions of the method : The catalytic cracking temperature is 1050°C, the pressure is normal pressure, the flow rate of methane gas is 16kg / h, the residence time of methane gas in the cracking reactor is 2.9s, the preheating temperature of the regeneration medium is 150°C, and the regeneration starting temperature is 760°C. The pressure is normal pressure, the flow rate of water vapor is 12.3kg / h, the flow rate of oxygen is 24.1kg / h, and the residence time of the regeneration medium in the regeneration reactor is 1.5s.

[0048] The reaction results are: methane cracking single-pass conversion rate reaches 100%, the volume percentage of hydrogen in the product gas reaches 100%, and the CO / H in th...

Embodiment 3

[0050] This embodiment also provides a method for the autothermal production of high-purity hydrogen by catalytic cracking of methane. The method uses an activated carbon catalyst and the device in Example 1. The specific steps of the method are the same as in Example 1. The reaction conditions of the method : The catalytic cracking temperature is 1100°C, the pressure is normal pressure, the flow rate of methane gas is 16kg / h, the residence time of methane gas in the cracking reactor is 2.8s, the preheating temperature of the regeneration medium is 300°C, and the regeneration starting temperature is 850°C. The pressure is normal pressure, the flow rate of water vapor is 13.5kg / h, the flow rate of oxygen is 21.9kg / h, and the residence time of the regeneration medium in the regeneration reactor is 1.5s.

[0051] The reaction results are: methane cracking single-pass conversion rate reaches 100%, the volume percentage of hydrogen in the product gas reaches 100%, and the CO / H in th...

Embodiment 4

[0053] This embodiment also provides a method for autothermal production of high-purity hydrogen by catalytic cracking of methane, which uses coke and the device in Example 1 (the cracking reactor adopts a moving bed, and the regenerative reactor adopts a fast fluidized bed). The specific steps of the method are the same as in Example 1, and the reaction conditions of the method: the catalytic cracking temperature is 1100°C, the pressure is normal pressure, the methane gas flow rate is 16kg / h, and the residence time of the methane gas in the cracking reactor is 3.2s, The preheating temperature of regeneration medium is 300°C, the starting temperature of regeneration is 830°C, the pressure is normal pressure, the flow rate of water vapor is 12.3kg / h, the flow rate of oxygen is 21.9kg / h, and the residence time of regeneration medium in the regeneration reactor is 1.5s.

[0054] The reaction results are: methane cracking single-pass conversion rate reaches 100%, the volume percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com