Powder storage bin fluidization device capable of being cleaned online

A storage bin and fluidizer technology, applied in the field of powder or granular conveying devices, can solve the problems of loss of elasticity, inability to seal the inner wall of the bin, complicated installation and replacement, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

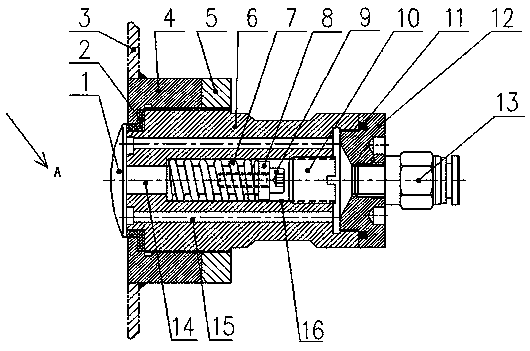

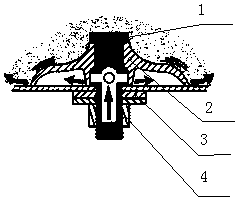

[0016] Please refer to the attached figure 1 As shown, the present invention is to fix an air valve on the storage bin wall 3, including a valve body 6 and a valve core. The valve core is made of a valve shaft 14 and a valve core cap 1. One end is filled with pressure gas, and the valve core cap 1 is affected by the pressure gas and leaves the storage bin wall 3. At the same time, the pressure gas is sprayed into the storage bin to break up the agglomerated and bridging materials; to remove the pressure gas, the spring 7 makes The valve shaft 14 shrinks inwardly, and the valve core cap 1 covers the jet nozzle of the valve body again.

[0017] One end of the valve shaft 14 is connected to the valve core cap 1, and the other end is screwed to the screw 9 through a washer 8. The right end of the screw 9 has a plug 10 screwed on the internal thread of the inner wall of the valve body 6, and the right end of the valve body 6 is connected with an end cap. 12 are screwed, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com