Focal plane rotating laser spot welding method

A technology of laser spot welding and welding method, which is applied in the field of material processing to achieve the effects of good weld quality, obvious technological advantages and increased weld width to depth ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

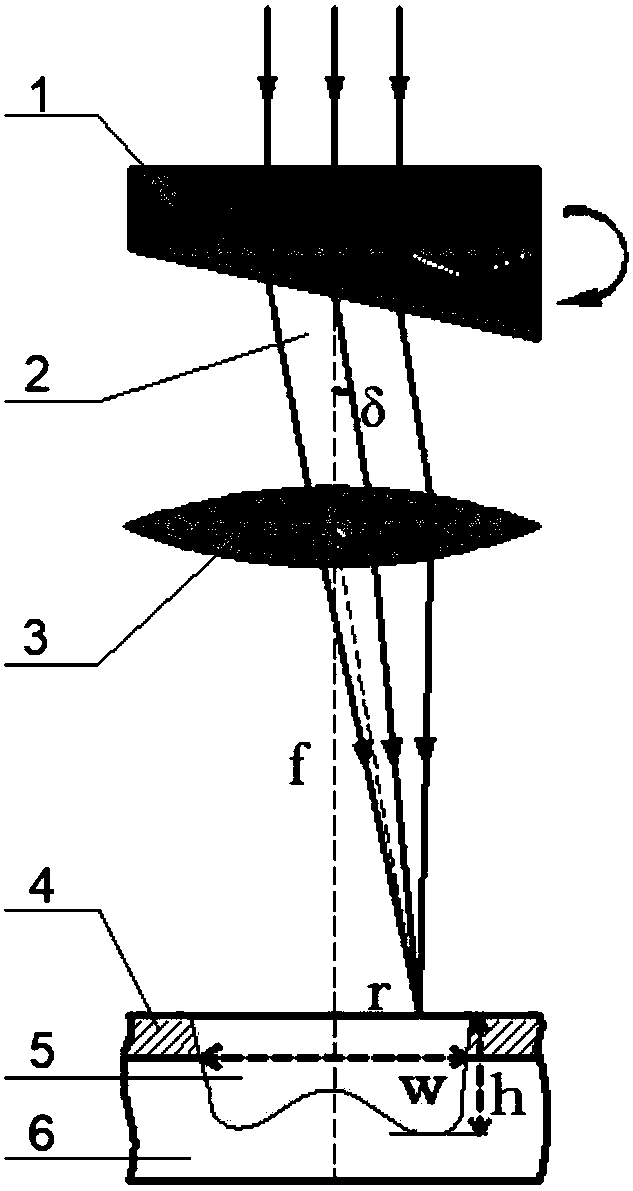

[0015] The equipment used includes: wedge lens, focusing lens, upper plate material, laser. From top to bottom, there are lasers, wedge lenses, focusing lenses, and upper plate materials. The laser emits parallel beams, and the parallel beams are vertical to the upper surface of the wedge lens, and then pass through the oblique lower surface of the wedge lens to reach the focus lens. The focus shift reaches the surface of the upper plate material, and during the welding process, the wedge-shaped lens is rotated at a constant speed, so that the focus is in a uniform circular motion on the upper plate material.

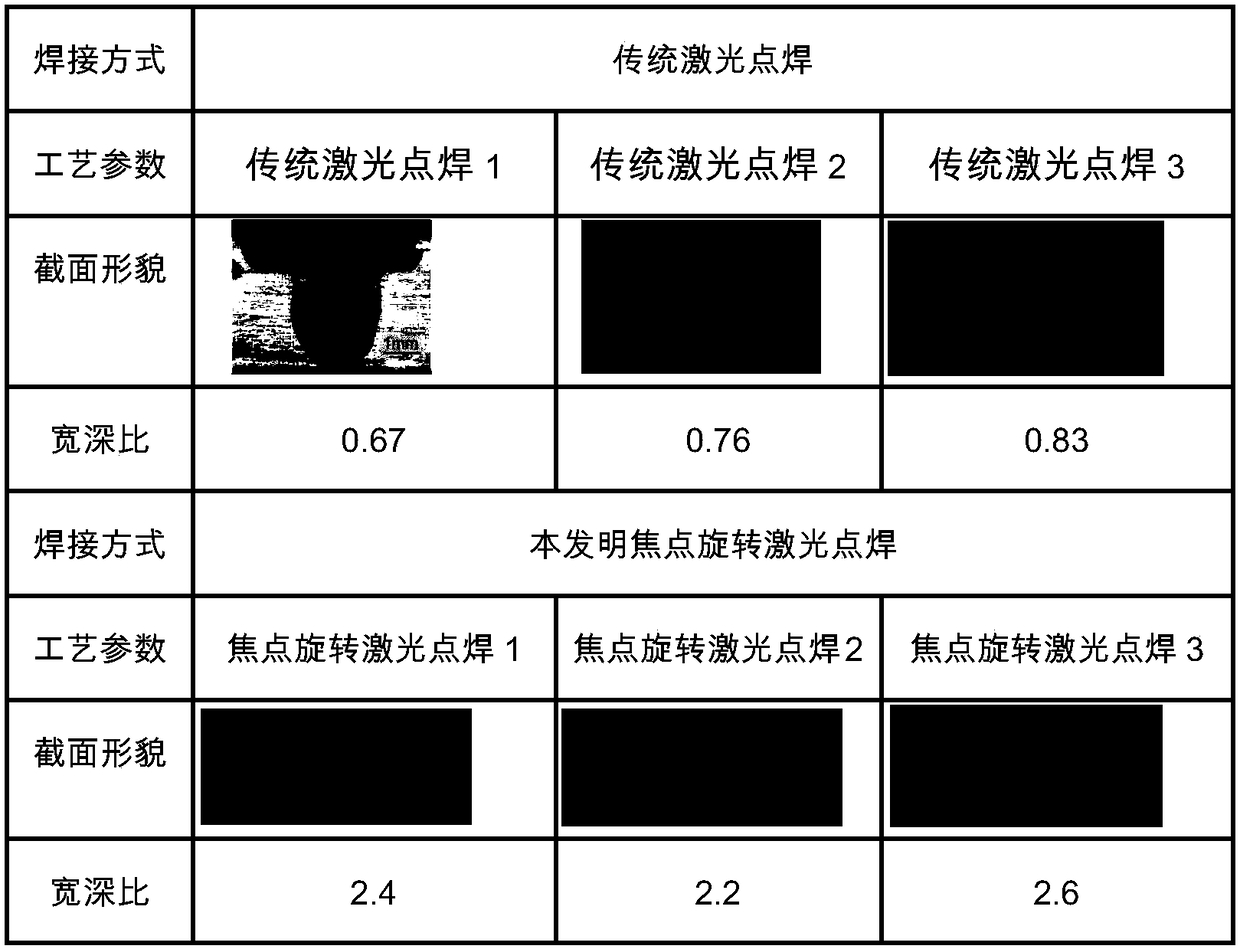

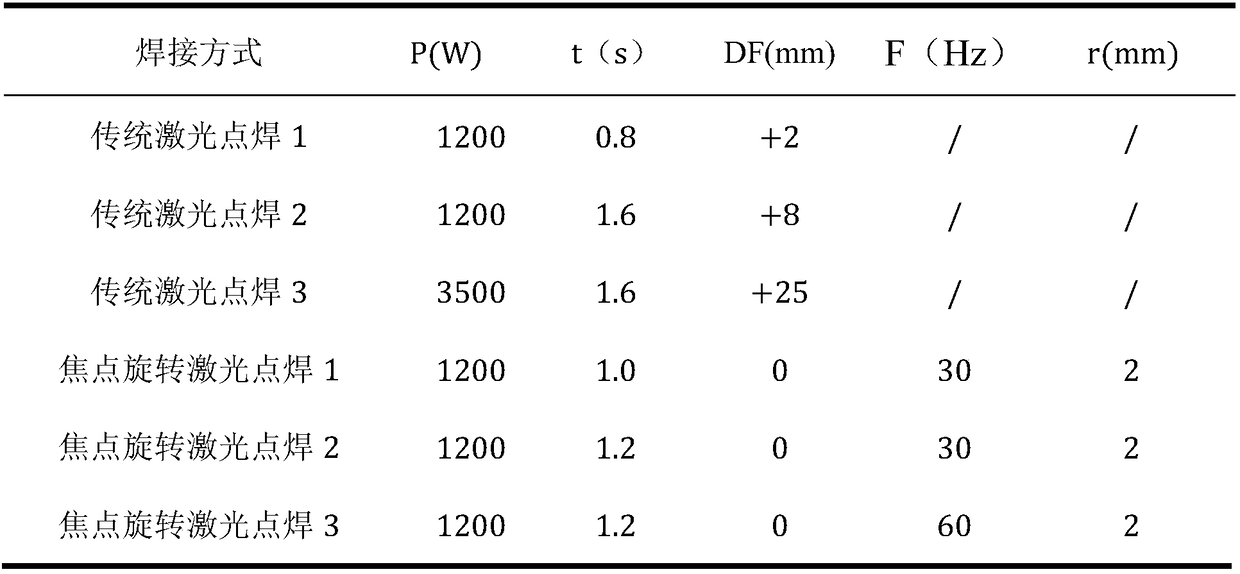

[0016] Embodiment 1 welding process parameter is as shown in the table below:

[0017]

[0018] Among them, P is the laser power, t is the spot welding time, DF is the defocus amount, and it is positive if the focus is on the surface of the workpiece, F is the focus rotation frequency, and r is the focus rotation radius. The laser used in this example is IPG-YLS6000 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com