A structure for scalding, cleaning and scraping skin of livestock tongue

A technology of blanching, skin scraping and blanching, which is applied in meat processing equipment, slaughtering, food science, etc., can solve the problems of poor taste and not easy to taste, and achieve the effect of ensuring the effect of marinating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

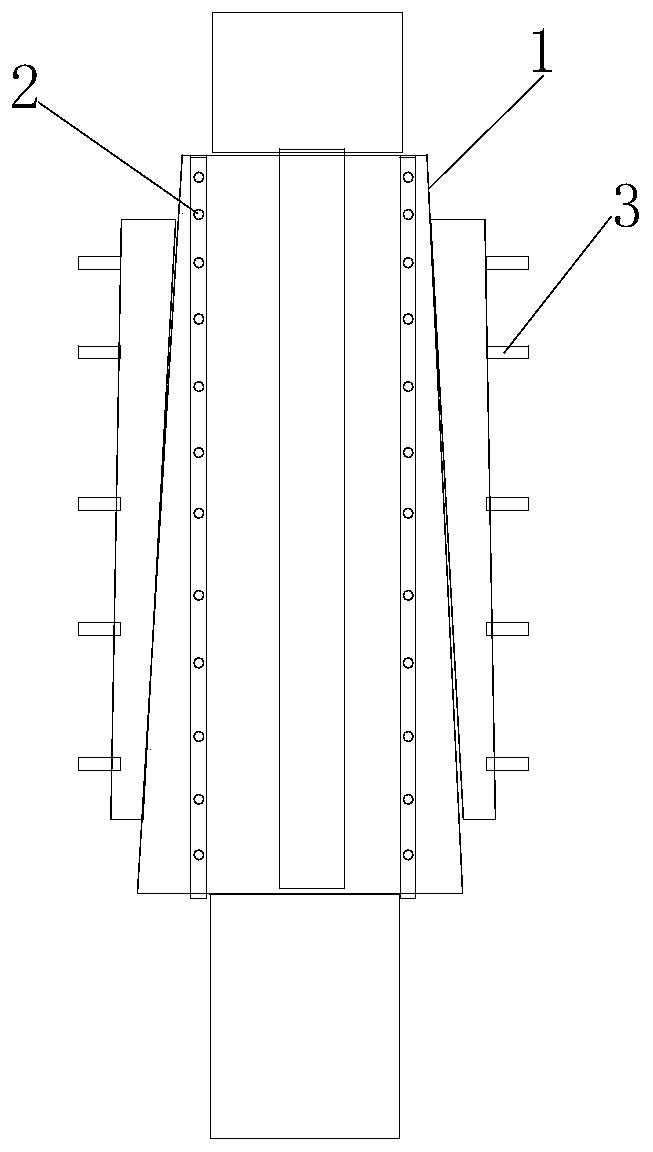

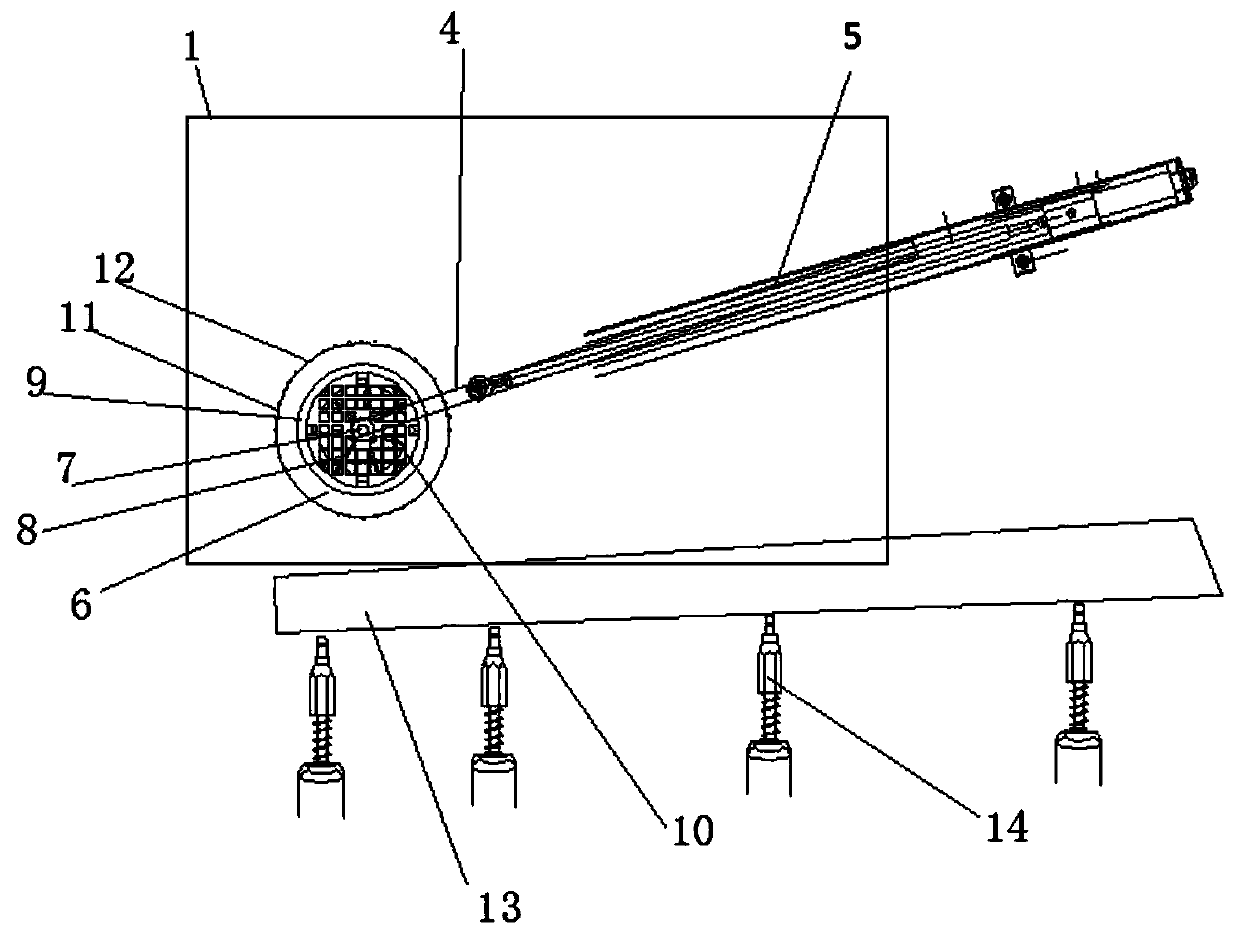

[0016] Example 1, such as figure 1 , 2 As shown in the figure, a blanching, cleaning and scraping structure of livestock tongue is characterized in that it includes an oblique pressing block structure arranged on a station, and a blanching and skin scraping structure arranged on the upper part of the oblique pressing block structure. , the blanching skin scraping structure includes a pressure sleeve 1 with a narrow upper end and a wide rear end, uniformly distributed steam through holes 2 are arranged on the upper part of the pressure sleeve, uniformly distributed water spray holes 3 are arranged on both sides of the pressure sleeve, The middle part of the cover is provided with a chute 4, and a pulling hob structure is set in the chute, and the outer side of the pulling hob structure is connected with the telescopic control cylinder 5.

[0017] The pulling hob structure includes a shaft center structure, a scraping surface structure arranged outside the shaft center structur...

Embodiment 2

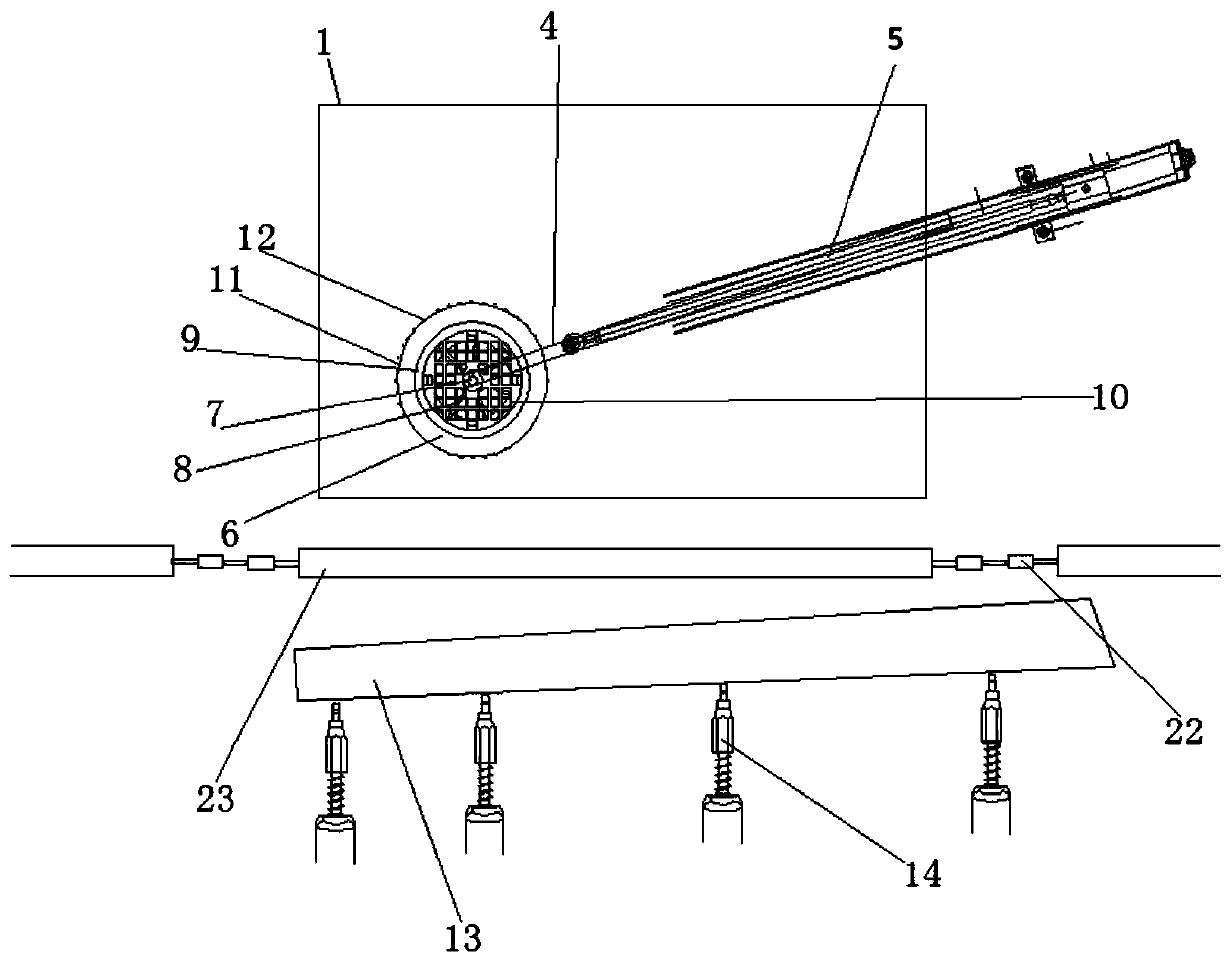

[0020] Example 2, such as Figure 4 As shown, on the basis of Example 1; the blanching spray jacket structure includes an external pressure body 1 that matches the pressure sleeve structure, the external pressure body is Π-shaped, and a top is arranged on the inside of the external pressure body. Press the limit groove 15, set the water flow interface 16 on the side inside the external pressure body, set the water storage bin 17 in the external pressure body corresponding to the position of the water flow interface, set the water injection port 18 outside the water storage bin, and set the water injection port 18 on the both sides of the top pressure limit groove. A steam docking port 19 is provided on the external pressure body, a heat storage chamber 20 is provided in the external pressure body corresponding to the steam docking port, and a steam injection port 21 is provided outside the heat storage chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com