High brightness liquid crystal display module

A liquid crystal display module, liquid crystal module technology, applied in non-polymer organic compound adhesives, optics, instruments, etc., can solve the problem of poor light transmittance of inorganic substances, more than the loss of brightness, and poor compatibility between inorganic substances and polymers and other problems, to achieve the effect of increasing the refractive index and solving the problem of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

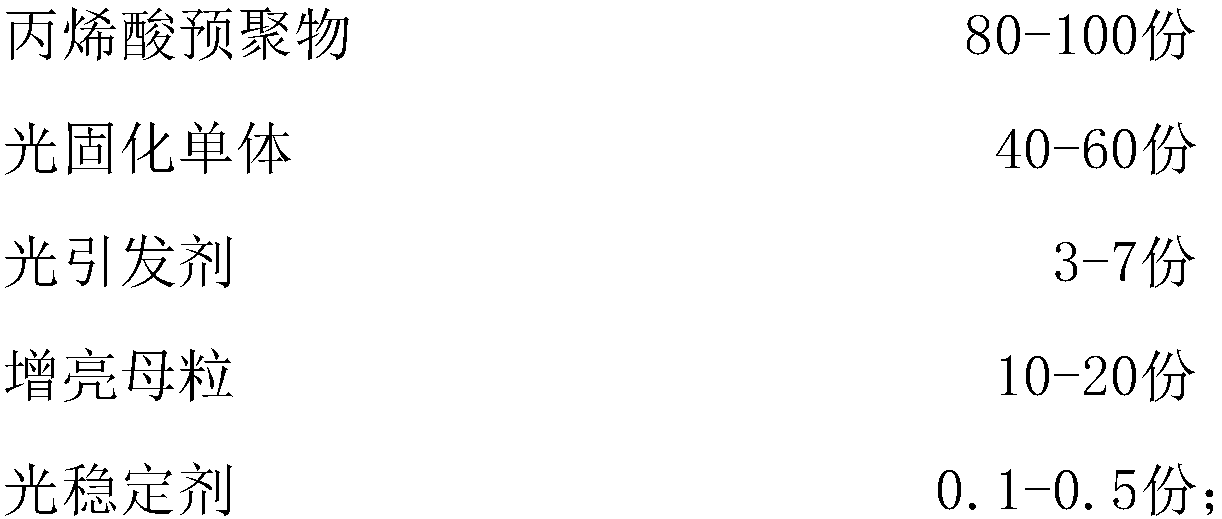

[0034] A high-brightness liquid crystal display module, including a backlight module and a liquid crystal module, the liquid crystal module is provided with a brightness-enhancing structural layer, and the brightness-enhancing structural layer is composed of several microprism strips, and the brightness-enhancing structural layer It is obtained by curing UV optical glue, and the UV optical glue is composed of the following raw materials in parts by weight:

[0035]

[0036] Described acrylic acid prepolymer is made by the raw material of following percentage by weight:

[0037]

[0038] The balance is acetone,

[0039] Wherein, the brightening masterbatch is a microsphere with a core-shell structure, the core of the microsphere with a core-shell structure is a high-refractive nanoparticle, and the shell is a polyimide microsphere.

[0040] Wherein, the preparation method of the brightening masterbatch comprises the following steps:

[0041] (1) Take 2,2-bis(3,4-dicarboxy...

Embodiment 2

[0057] A high-brightness liquid crystal display module, including a backlight module and a liquid crystal module, the liquid crystal module is provided with a brightness-enhancing structural layer, and the brightness-enhancing structural layer is composed of several microprism strips, and the brightness-enhancing structural layer It is obtained by curing UV optical glue, and the UV optical glue is composed of the following raw materials in parts by weight:

[0058]

[0059] Described acrylic acid prepolymer is made by the raw material of following percentage by weight:

[0060]

[0061] The balance is acetone,

[0062] Wherein, the brightening masterbatch is a microsphere with a core-shell structure, the core of the microsphere with a core-shell structure is a high-refractive nanoparticle, and the shell is a polyimide microsphere.

[0063] Wherein, the preparation method of the brightening masterbatch comprises the following steps:

[0064] (1) Take 2,2-bis(3,4-dicarbo...

Embodiment 3

[0080] A high-brightness liquid crystal display module, including a backlight module and a liquid crystal module, the liquid crystal module is provided with a brightness-enhancing structural layer, and the brightness-enhancing structural layer is composed of several microprism strips, and the brightness-enhancing structural layer It is obtained by curing UV optical glue, and the UV optical glue is composed of the following raw materials in parts by weight:

[0081]

[0082] Described acrylic acid prepolymer is made by the raw material of following percentage by weight:

[0083]

[0084] The balance is acetone,

[0085] Wherein, the brightening masterbatch is a microsphere with a core-shell structure, the core of the microsphere with a core-shell structure is a high-refractive nanoparticle, and the shell is a polyimide microsphere.

[0086] Wherein, the preparation method of the brightening masterbatch comprises the following steps:

[0087] (1) Take 2,2-bis(3,4-dicarbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com