Automatic sampling mechanism for blood analyzer in clinical laboratory of hospital

A blood analysis and automatic sampling technology, applied in the direction of sampling devices, etc., can solve problems such as low efficiency, deviation of analysis results, complex structure, etc., and achieve the effect of increasing sampling speed, improving accuracy and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

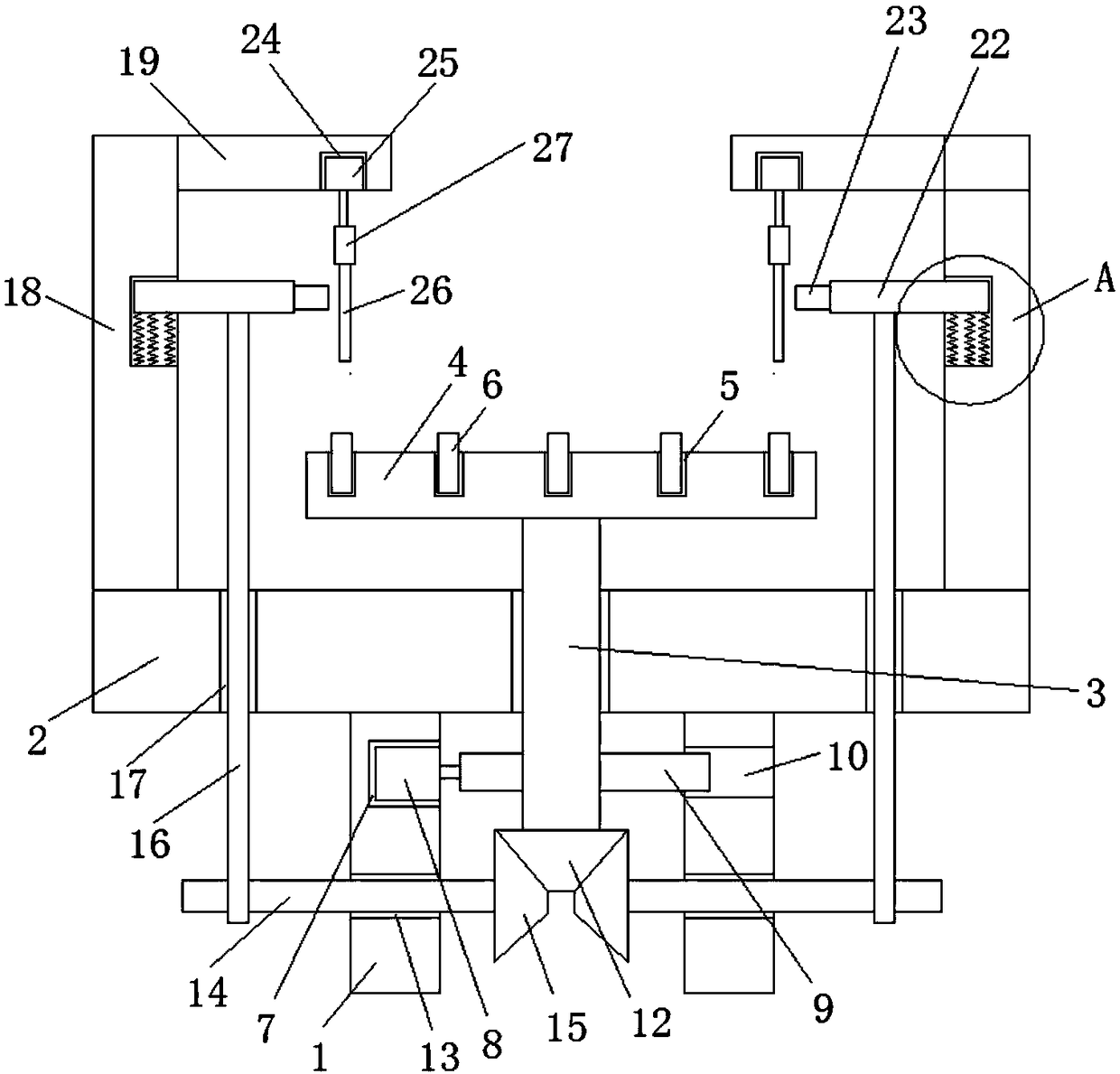

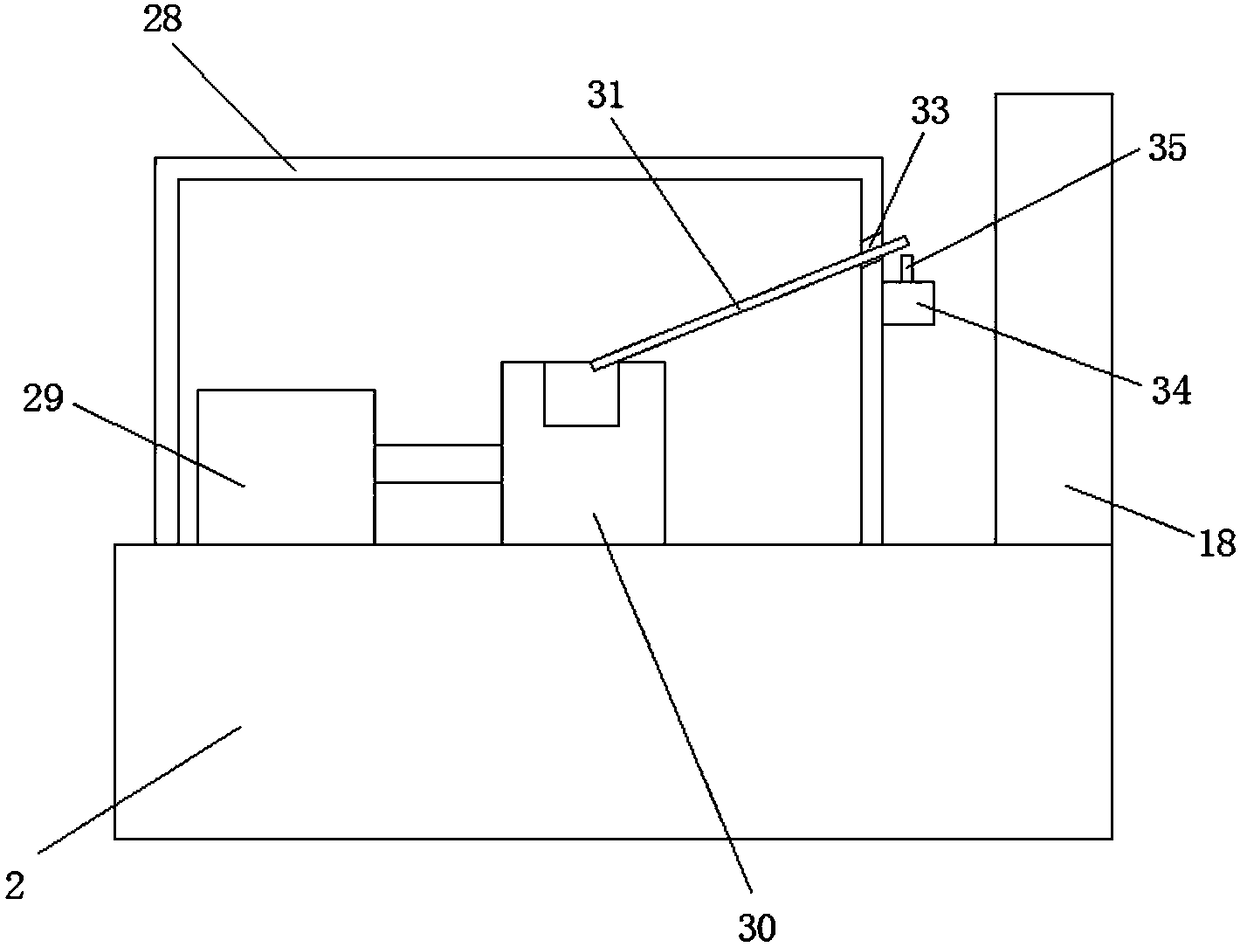

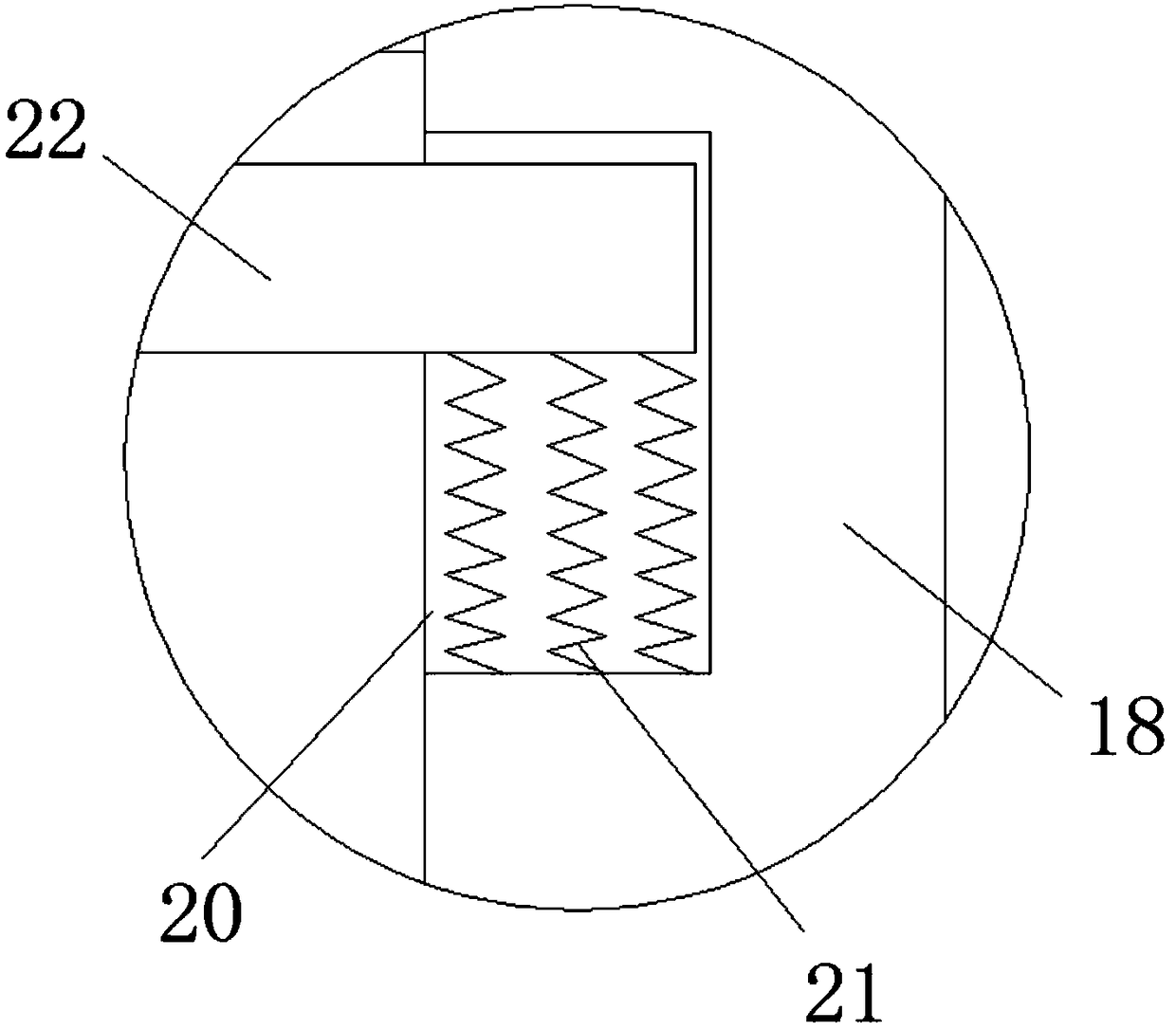

[0026] refer to Figure 1-5In this embodiment, an automatic sampling mechanism for a blood analysis instrument in a laboratory laboratory of a hospital is proposed. There is a first rotating hole, and the first rotating shaft 3 is rotated in the first rotating hole. The top of the first rotating shaft 3 extends above the placement plate 2 and is welded with a rotating plate 4. The top of the rotating plate 4 is provided with a plurality of test tubes groove 5, and a test tube 6 is placed in the test tube groove 5, a first installation groove 7 and a push hole 10 are opened on the sides of the two support plates 1 close to each other, and a first push rod motor 8 is installed in the first installation groove 7 , and the first push plate 9 is welded on the output shaft of the first push rod motor 8, and the side of the first push plate 9 away from the first push rod motor 8 extends into the push hole 10; the bottom end of the first rotating shaft 3 Extending to the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com