A kind of ni-fe-mo-cu porous material and preparation method thereof

A ni-fe-mo-cu, porous material technology, applied in separation methods, chemical instruments and methods, metal processing equipment, etc. High temperature and alkali corrosion resistance, long service life, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

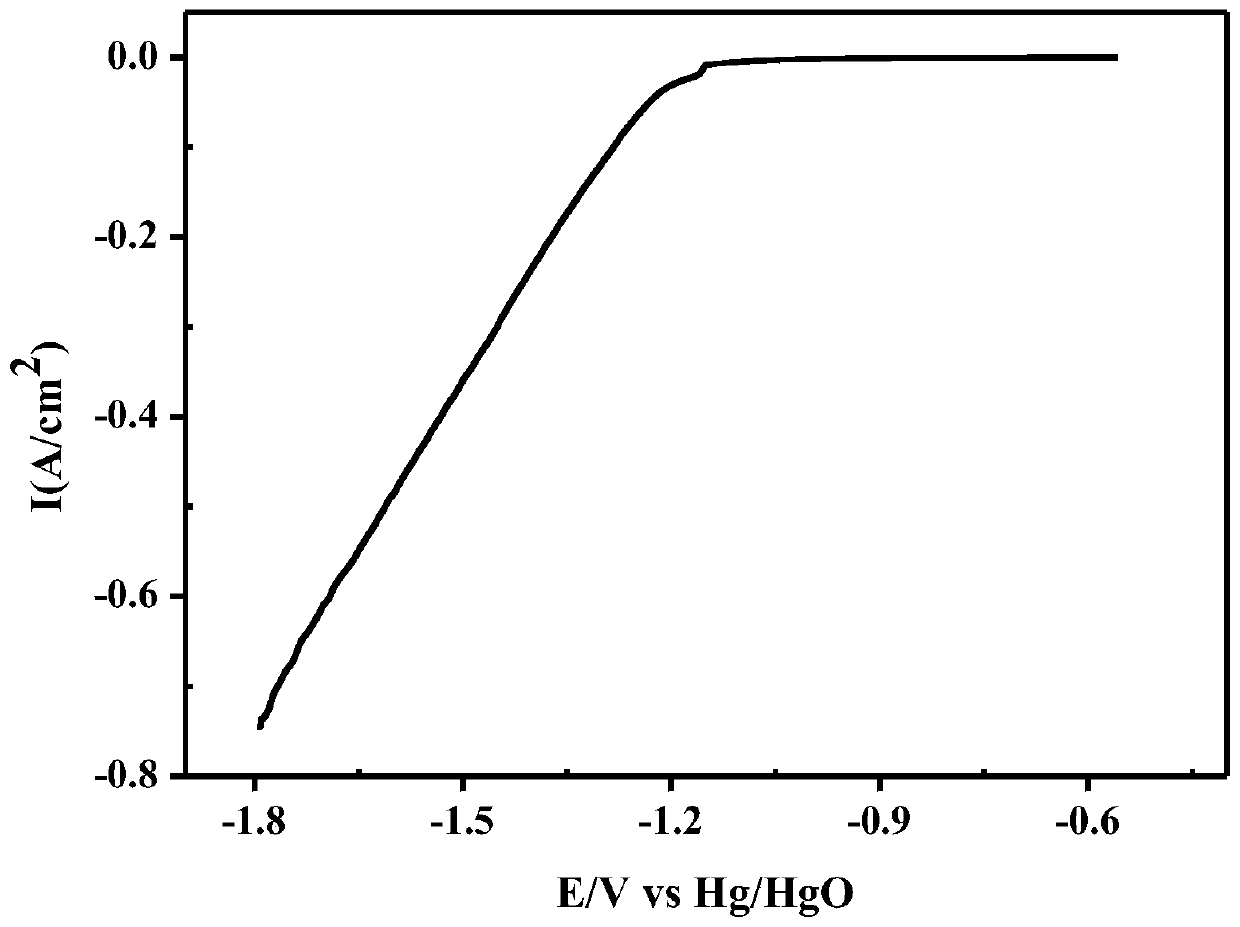

Image

Examples

Embodiment 1

[0024] Four high-purity element powders of Ni, Fe, Mo, and Cu were prepared according to the mass percentage, and the Fe content was 15%, the powder particle size was 3µm; the Mo content was 2%, the powder particle size was 3µm; the Cu content was 7% , the powder particle size is 3µm; the balance is Ni powder with a powder particle size of 10µm. Put the prepared powder on a V-type powder mixer and mix it at a constant speed for 8 hours, then add stearic acid of 1% of the total powder mass, dry for 6 hours, and cold press at 200 MPa under a cold press for 30 seconds; Place the pressed sample in a vacuum furnace at a vacuum of 1×10 -2 In the case of Pa, keep a heating rate of 5°C / min from room temperature to 240°C and keep it for 60 minutes; then raise the temperature to 300°C at a rate of 10°C / min and keep it for 100 minutes; then raise the temperature at a rate of 8°C / min to 680°C and keep at this temperature for 120min; then raise the temperature to 940°C at a heating rate o...

Embodiment 2

[0028] The four high-purity element powders of Ni, Fe, Mo, and Cu are prepared according to the mass percentage, and the content of Fe is 35%, the particle size of the powder is 10µm; the content of Mo is 5%, the particle size of the powder is 10µm; the content of Cu is 2% , the powder particle size is 3µm; the balance is Ni powder with a powder particle size of 3µm. Put the prepared powder on a V-type powder mixer and mix it at a constant speed for 10 hours, then add stearic acid of 3% of the total powder mass, dry for 12 hours, and cold press at a pressure of 50MPa under a cold press for 120s; Place the pressed sample in a vacuum furnace at a vacuum of 1×10 -3 In the case of Pa, keep the temperature rise rate of 6°C / min from room temperature to 120°C and keep it for 40 minutes; then raise the temperature to 340°C at a rate of 3°C / min and keep it for 80 minutes; then raise the temperature at a rate of 4°C / min to 480°C and keep at this temperature for 90 minutes; then raise t...

Embodiment 3

[0031] The four high-purity element powders of Ni, Fe, Mo, and Cu were prepared according to the mass percentage, and the content of Fe was 25%, the particle size of the powder was 5µm; the content of Mo was 6%, the particle size of the powder was 8µm; the content of Cu was 5% , the powder particle size is 6µm; the balance is Ni powder with a powder particle size of 7µm. Put the prepared powder on a V-type powder mixer and mix at a constant speed for 16 hours, then add 1.5% stearic acid of the total mass of the powder, dry for 11 hours, and cold press at 180 MPa under a cold press for 50 seconds; Place the pressed sample in a vacuum furnace at a vacuum of 5×10 -3 In the case of Pa, maintain a heating rate of 10°C / min from room temperature to 180°C, and keep it for 50 minutes; then raise the temperature to 420°C at a heating rate of 5°C / min, and keep it for 90 minutes; then raise the temperature at a heating rate of 5°C / min to 560°C and keep at this temperature for 95min; then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com