Construction material conveying apparatus

A technology for conveying devices and buildings, which is used in hoisting devices, transportation and packaging, lifting equipment braking devices, etc. The effect of high degree and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

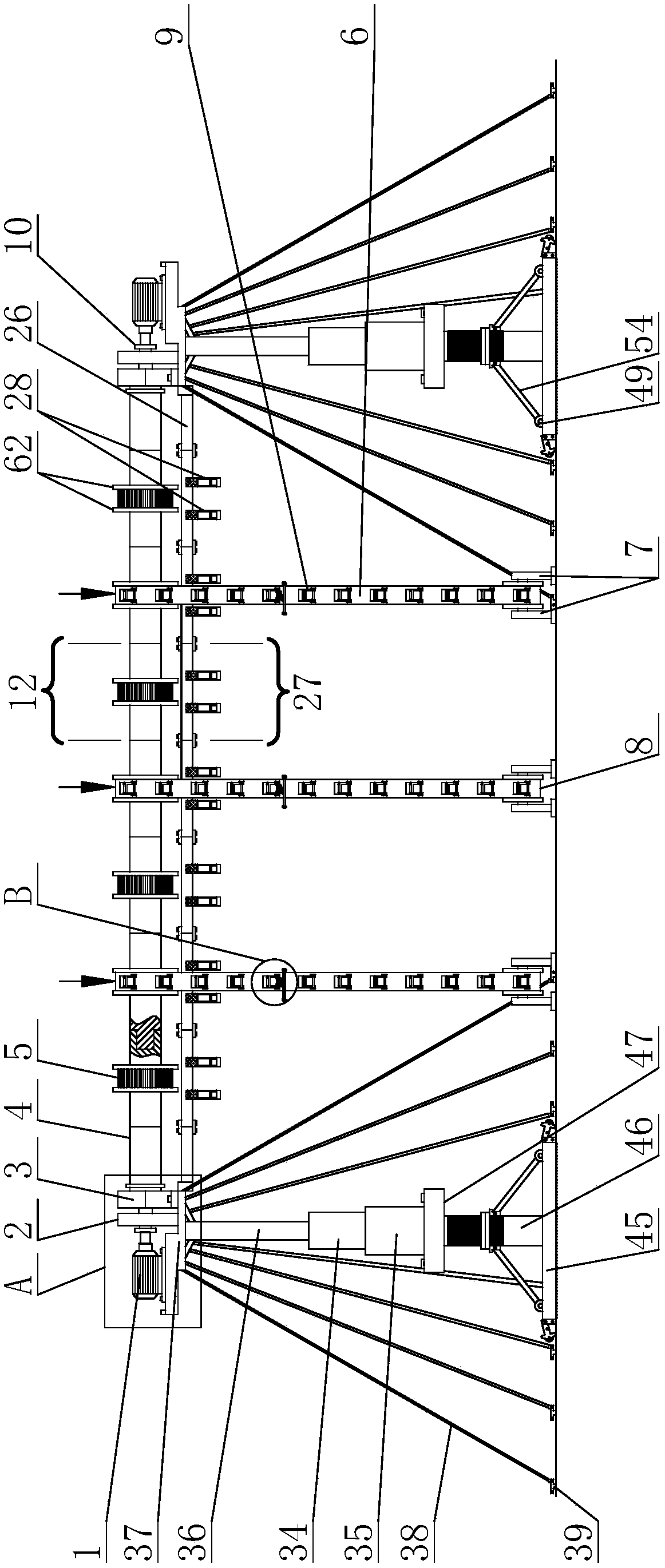

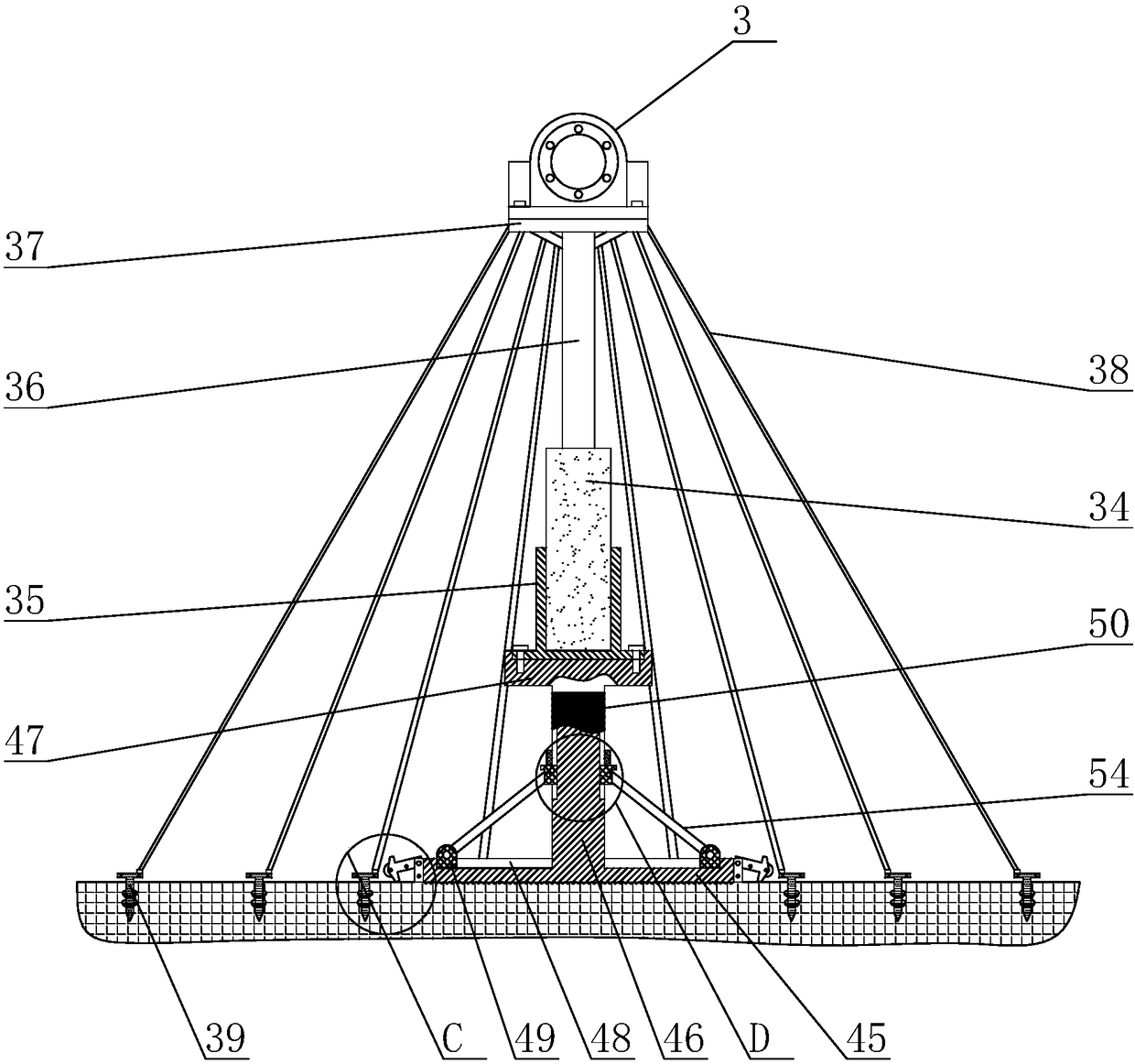

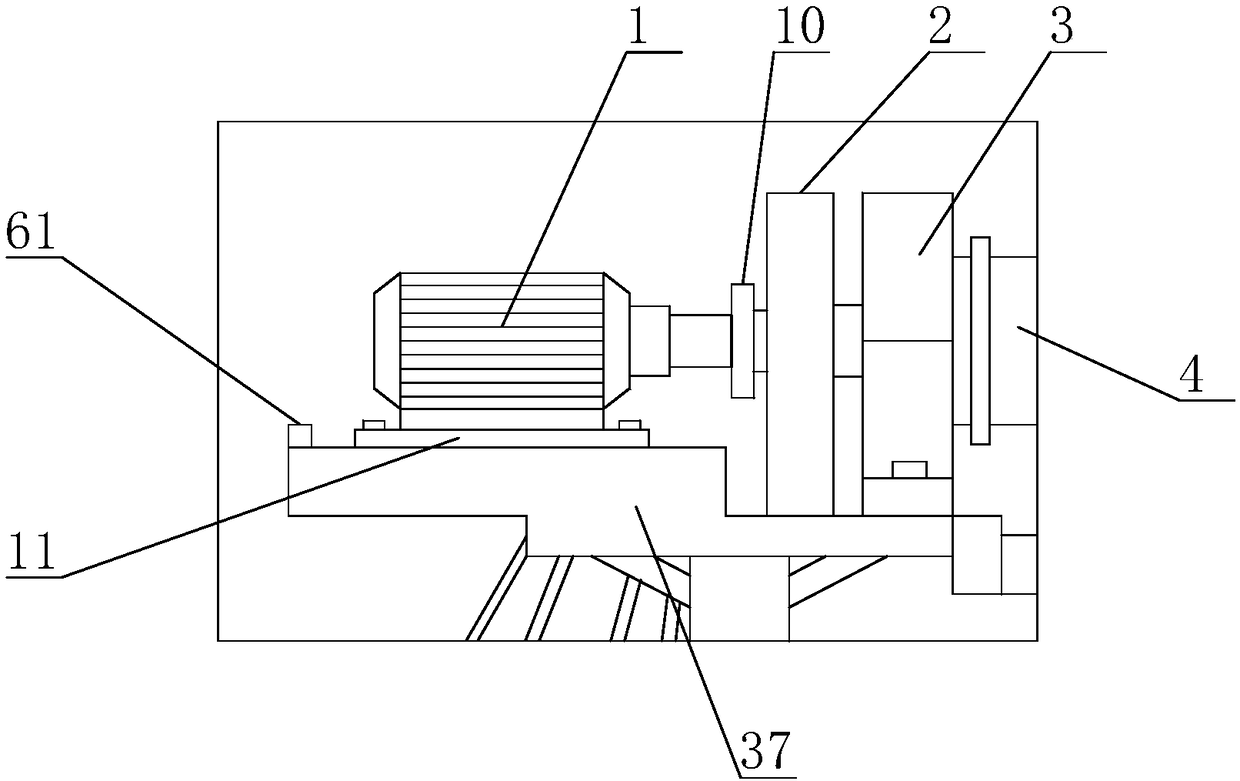

[0048] As attached to the manual figure 1 As shown, the present invention is a construction material conveying device. The main structure includes two adjustable support frames, a driving mechanism and a material conveying mechanism. The driving mechanism includes a driving motor 1, a reducer 2, a top bearing seat 3 and Drive the main shaft 4, the driving motor 1, the reducer 2, and the top bearing seat 3 are arranged on the top of the adjustable support frame, the driving motor 1 is connected with the driving main shaft 4 through the speed reducer 2, and the driving main shaft 4 is provided with There are several driving gears 5, seven of which are provided in this embodiment; the material conveying mechanism includes a transmission toothed belt 6, a bottom bearing seat 7 and a driven gear 8 arranged on the ground, and the transmission toothed belt 6 is tightly arranged on Between the driving gear 5 and the driven gear 8 , the rotating shafts at both ends of the driven gear 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com