Preparation process of wear-resistance kitchen knife

A preparation process and technology of kitchen knives, applied in the field of preparation technology of wear-resistant kitchen knives, can solve problems such as poor quality of knives, and achieve the effects of convenient cost control, improved bargaining space, toughness and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation process of the wear-resistant kitchen knife in this embodiment is as follows:

[0031] 1. Decontamination treatment on the surface of the billet

[0032] Using 45# steel as the blade material, the outer surface of the billet is initially polished with 200#~400# grit sandpaper to remove the rust and stains on the surface to obtain a smoother outer surface, which is the next step of plasma spray welding prepare.

[0033] 2. Heating pretreatment of billet surface

[0034] Use a portable spray gun to heat the surface of the 45# billet treated in step 1, and the heating time is 30-60s. If plasma spray welding is performed directly on the surface of the steel billet, the high temperature during plasma spray welding will cause uneven heating of the steel billet, which will lead to cracks in the obtained wear-resistant coating, so the steel billet needs to be preheated first.

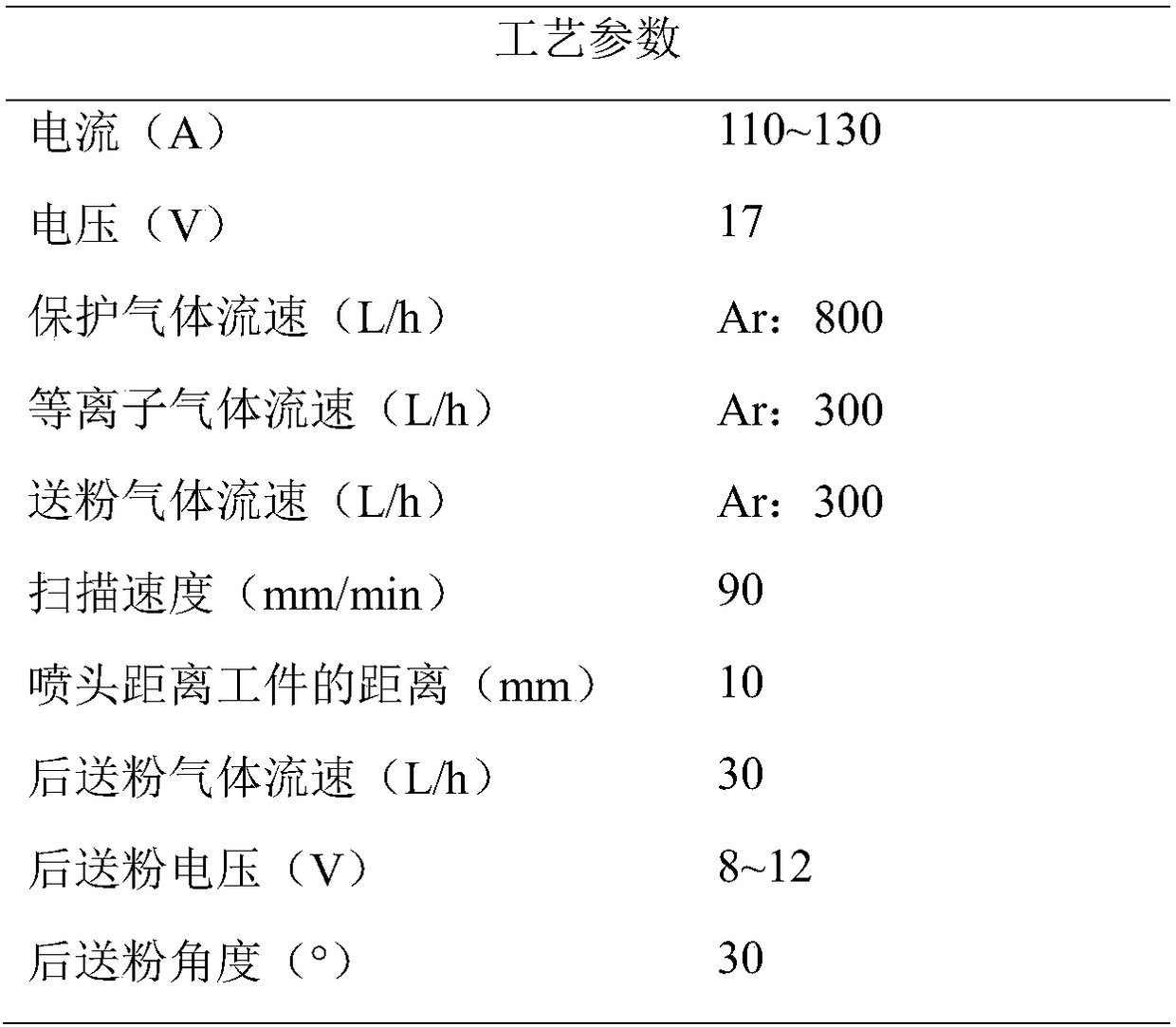

[0035] 3. Prepare wear-resistant coating by plasma spray welding

[0036] Fe313 iron-based sel...

Embodiment 2

[0046] The preparation process of the wear-resistant kitchen knife in this embodiment is as follows:

[0047] 1. Decontamination treatment on the surface of the billet

[0048] Using 3Cr13 stainless steel as the blade material, the outer surface of the billet is initially polished with 200#~400# grit sandpaper to remove the rust and stains on the surface to obtain a smoother outer surface, which is used for the next plasma spray welding. ready.

[0049] 2. Heating pretreatment of billet surface

[0050] Use a portable spray gun to heat the surface of the billet treated in step 1, and the heating time is 40-60s. If plasma spray welding is performed directly on the surface of the steel billet, the high temperature during plasma spray welding will cause uneven heating of the steel billet, which will lead to cracks in the obtained wear-resistant coating, so the steel billet needs to be preheated first.

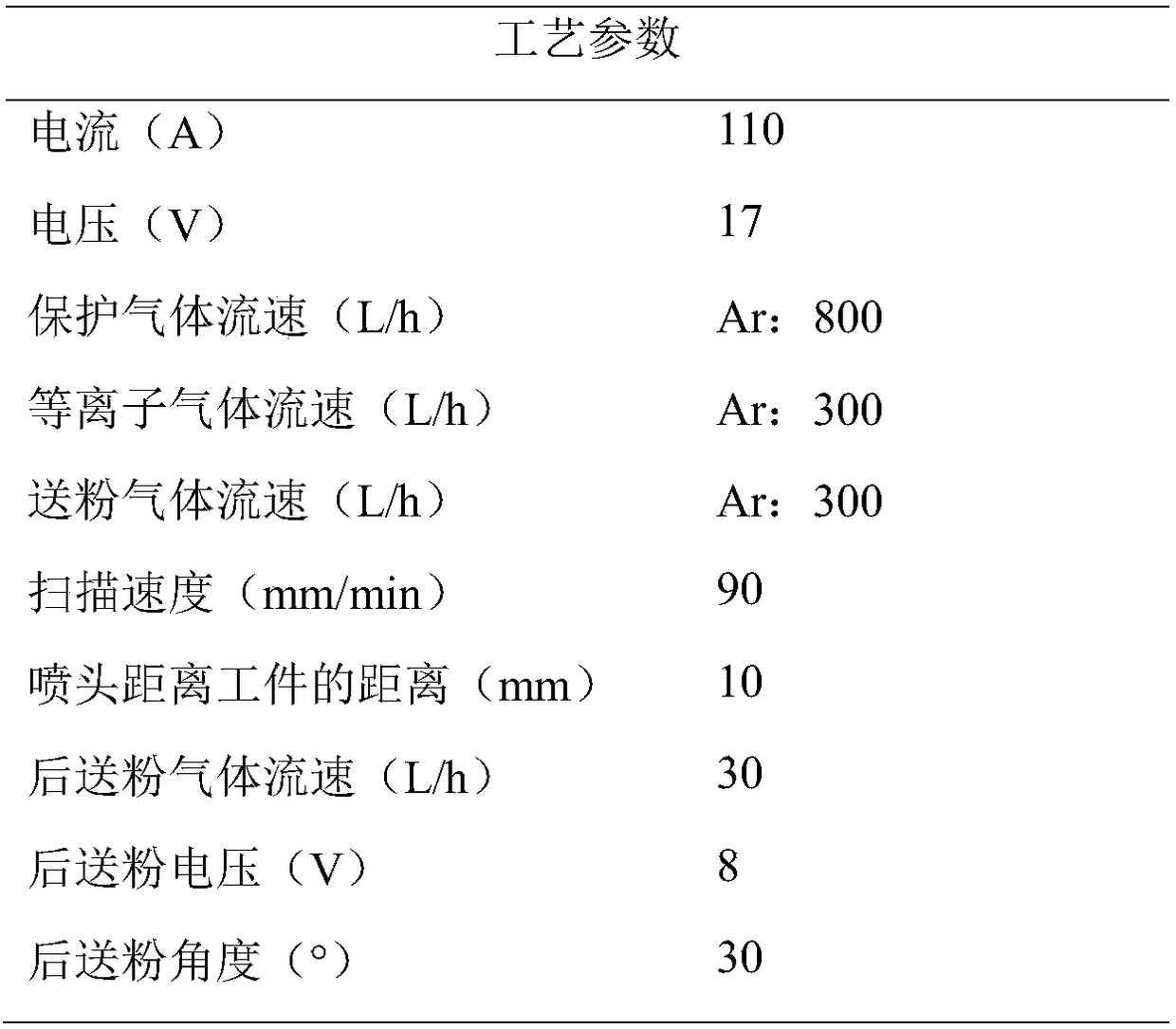

[0051] 3. Prepare wear-resistant coating by plasma spray welding

[0052] Fe313 iron-b...

Embodiment 3

[0062] The preparation process of the wear-resistant kitchen knife in this embodiment is as follows:

[0063] 1. Decontamination treatment on the surface of the billet

[0064] Using T10 high-carbon steel as the blade material, the outer surface of the billet is preliminarily polished with 200#~400# grit sandpaper to remove rust and stains on the surface to obtain a smoother outer surface, which is the next step for plasma spraying. Prepare for welding.

[0065] 2. Heating pretreatment of billet surface

[0066] Use a portable spray gun to heat the surface of the billet treated in step 1, and the heating time is 40-60s. If plasma spray welding is performed directly on the surface of the steel billet, the high temperature during plasma spray welding will cause uneven heating of the steel billet, which will lead to cracks in the obtained wear-resistant coating, so the steel billet needs to be preheated first.

[0067] 3. Prepare wear-resistant coating by plasma spray welding

[0068] Fe3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com