Safe pressure steam sterilization pot high in residual heat utilization rate

A safe pressure and steam sterilization technology, applied in applications, heat exchangers, indirect heat exchangers, etc., can solve problems such as poor sterilization effect, energy waste, complex structure, etc., to achieve convenient placement and removal of items, avoid Waste of energy, effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

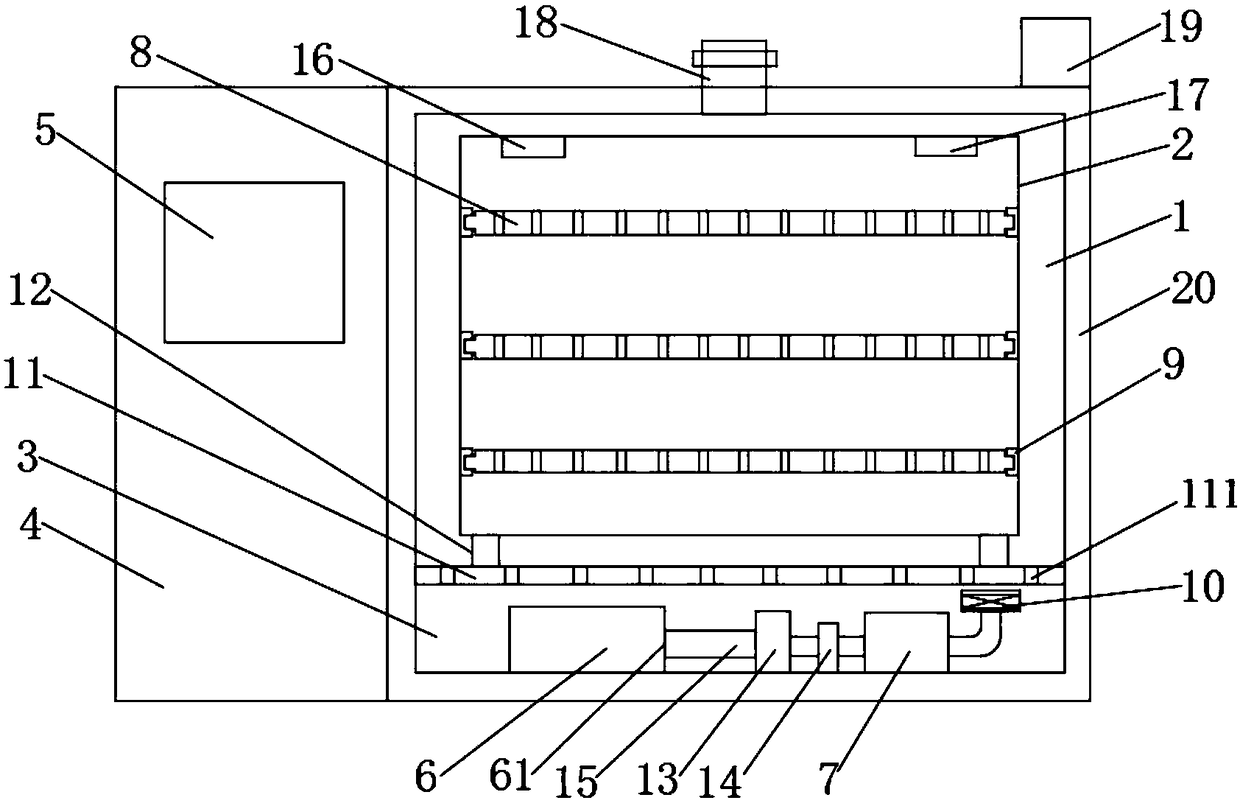

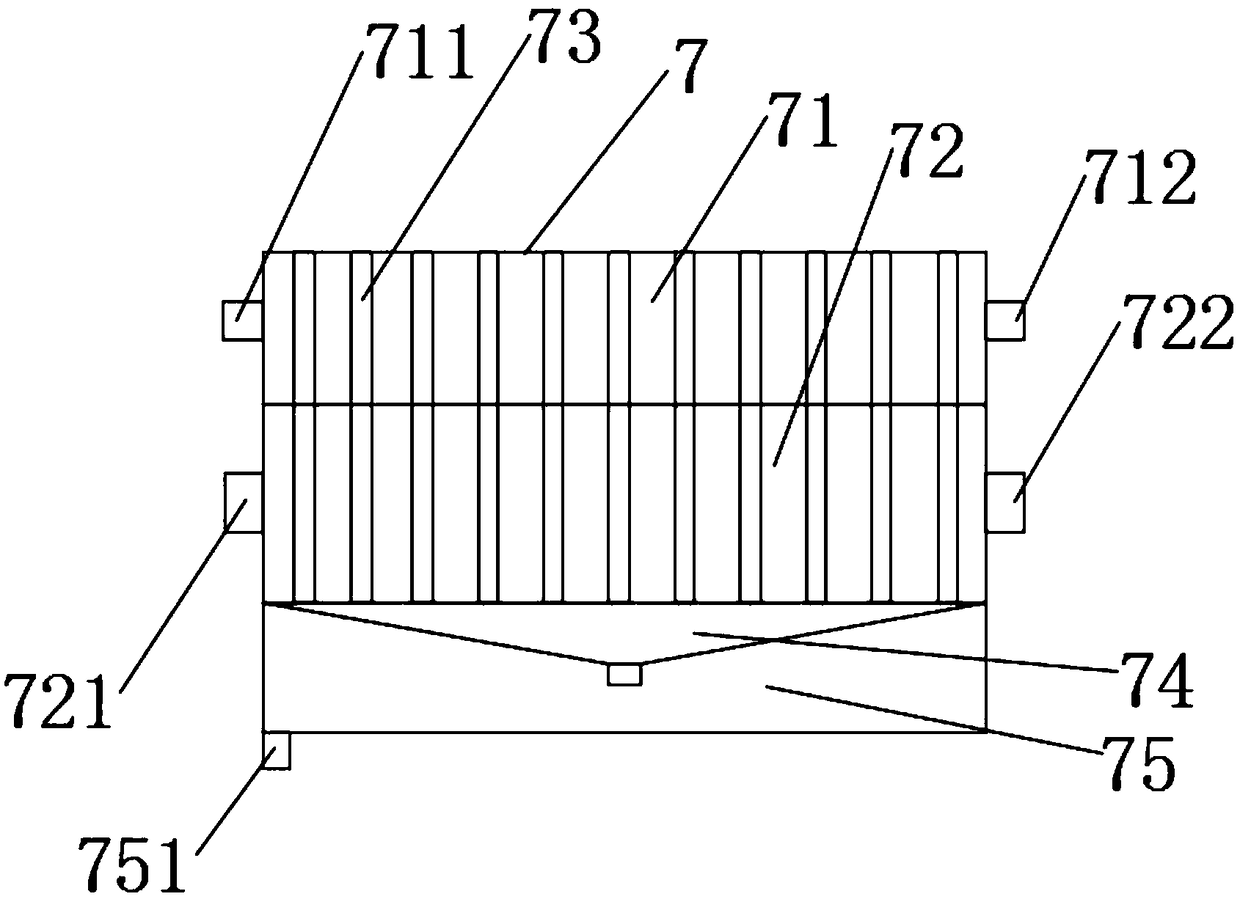

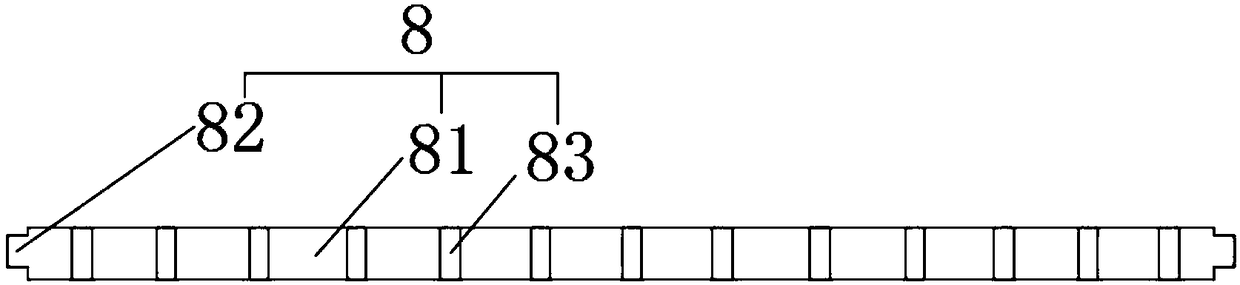

[0023] A safe pressure steam sterilizer with high waste heat utilization rate of the present invention, such as Figure 1-3 As shown, it includes a sterilization box 1, a sterilization chamber 2 is provided inside the sterilization box 1, and a sealed door (not shown) is provided on the outside of the front of the sterilization box 1, and the sterilization chamber 2 The outer walls are provided with a number of steam holes (not shown), the inside of the sterilization chamber 2 is provided with a number of horizontally parallel steaming plates 8, and the lower end of the sterilization chamber 2 is provided with longitudinally arranged slide rails 12. The bottom end of the sterilization chamber 2 is slidably arranged on the slide rail 12, and the lower end of the slide rail 12 is provided with a horizontally arranged partition 11. The lower end of the plate 11 is provided with a steam generating chamber 3, and the steam generating chamber 3 is provided with a steam generating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com