Three kinds of welded meshes of deformed rebars and preparation method

A technology of welded steel mesh and steel mesh, applied in the direction of online mesh, structural elements, building components, etc., can solve problems such as tying, difficulties, application obstacles and other problems of wall reinforcement at the floor of the floor beam, so as to save raw material consumption and reduce labor requirements. , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

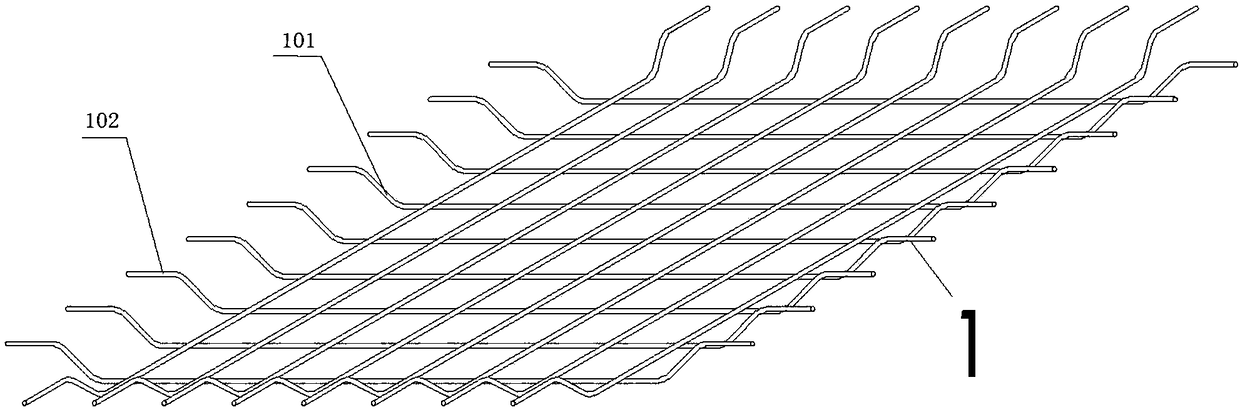

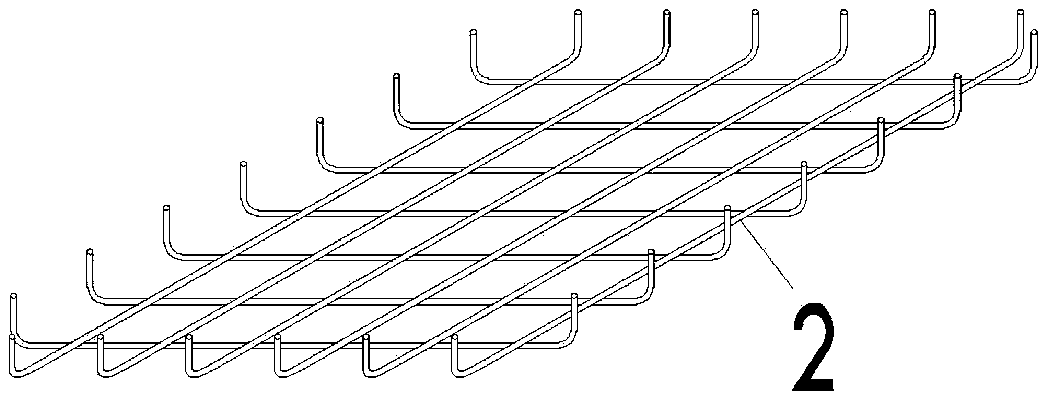

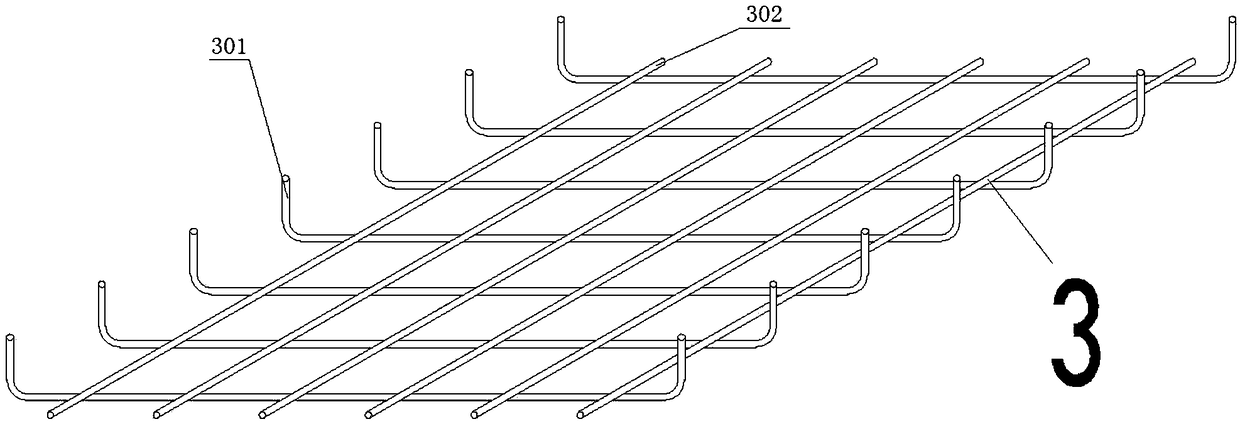

[0028] Three kinds of special-shaped steel bar welded mesh and its preparation method, such as Figure 1 ~ Figure 4 As shown, it includes the special-shaped steel bar welded mesh at the bottom of the concrete slab 1, the special-shaped steel bar welded mesh at the top of the concrete slab corner 2, the special-shaped steel bar welded mesh at the top of the concrete slab edge 3, the steel mesh welding machine 4, and the bending device at the end of the transverse steel bar of the steel welded mesh 5 and the bending device 6 at the end of the longitudinal reinforcement of the welded steel mesh;

[0029] The special-shaped welded steel bar mesh 1 at the bottom of the concrete slab is to bend the steel bar end of the bottom steel bar welded net of the concrete slab upward; it is characterized in that: the steel bar end of the special-shaped steel bar welded net 1 at the bottom of the concrete slab is provided with a bent section steel bar 101, one end of the bent section steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com