Heat supply boiler and pipeline descaling agent

The technology of heating boiler and descaling agent is applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc., and can solve the problems of easy generation of scale, cumbersome treatment process, affecting the normal flow of hot water, etc. Achieve the effect of keeping clean and hygienic, speeding up the reaction rate and good descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

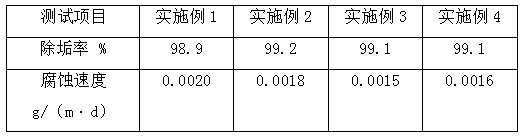

Examples

Embodiment 1

[0020] A descaling agent for heating boilers and pipelines. According to the parts by mass, the descaling agent comprises the following components: 40 parts of organic acid, 10 parts of sodium dihexene triamine pentamethylene phosphonate, 7 parts of sodium thiosulfate pentahydrate Parts, 6 parts of dodecyl dimethyl benzyl ammonium chloride, 16 parts of binder, 2 parts of non-surfactant, 6 parts of corrosion inhibitor, 4 parts of rust inhibitor, 3 parts of fungicide, chelating agent 5 servings.

[0021] Among them, the organic acid is selected from glycolic acid; the rust remover is selected from triethanolamine, and the bactericide is isothiazolinone; the binder contains water-soluble rubber powder, sodium metasilicate and sodium hydroxymethylcellulose, and the mass ratio of the three is It is 2:2:5. The corrosion inhibitor is a mixture of hexamethylenetetramine and sodium dodecylbenzenesulfonate, and the mass ratio of the two is 1:3. Chelating agent selects disodium salt of...

Embodiment 2

[0025] A descaling agent for heating boilers and pipelines. According to the parts by mass, the descaling agent comprises the following components: 50 parts of organic acid, 15 parts of sodium dihexene triamine pentamethylene phosphonate, 13 parts of sodium thiosulfate pentahydrate Parts, 9 parts of dodecyl dimethyl benzyl ammonium chloride, 20 parts of binder, 3 parts of non-surfactant, 8 parts of corrosion inhibitor, 6 parts of rust inhibitor, 6 parts of fungicide, chelating agent 8 servings.

[0026] Wherein, the organic acid is selected from the mixture of sulfamic acid and citric acid in any ratio. The rust remover is triethanolamine, and the fungicide is isothiazolinone; the binder contains water-soluble rubber powder, sodium metasilicate and sodium hydroxymethylcellulose, and the mass ratio of the three is 2:2:5. The corrosion inhibitor is a mixture of hexamethylenetetramine and sodium dodecylbenzenesulfonate, and the mass ratio of the two is 1:3. The chelating agent ...

Embodiment 3

[0030] A descaling agent for heating boilers and pipelines. According to the parts by mass, the descaling agent comprises the following components: 45 parts of organic acid, 13 parts of sodium dihexene triamine pentamethylene phosphonate, 10 parts of sodium thiosulfate pentahydrate Parts, 8 parts of dodecyl dimethyl benzyl ammonium chloride, 18 parts of binder, 2.5 parts of non-surfactant, 7 parts of corrosion inhibitor, 5 parts of rust inhibitor, 5 parts of fungicide, chelating agent 7 servings.

[0031] Wherein, the organic acid is selected from the mixture of glycolic acid and aminotrimethylene phosphoric acid in any ratio. Use triethanolamine as the rust remover, and isothiazolinone as the fungicide; the binder contains water-soluble rubber powder, sodium metasilicate and sodium hydroxymethylcellulose, and the mass ratio of the three is 2:2:5; The etchant is a mixture of hexamethylenetetramine and sodium dodecylbenzenesulfonate, the mass ratio of the two is 1:3; the chela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com