Yellow light fluorescent powder for white light LED and preparation method thereof

A yellow fluorescent powder and fluorescent powder technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of increased design difficulty and cost consumption, unfavorable warm white LED lighting, and high color temperature of white LEDs, and achieve integrated The effect of modernized and integrated design, enhanced color rendering index, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] a Ba 3 Y 4 o 9 : The preparation method of Ce (x=0.2 at. %) yellow phosphor powder is as follows:

[0053] With Ba(NO 3 ) 2 , Y(NO 3 ) 3 and Ce(NO 3 ) 3 As the initial raw material, the molar ratio of Ba:Ce:Y is 3:0.008:3.992 for batching, and each raw material is ball milled for 5 h to obtain a mixed powder with an average particle size of 0.5-5 μm;

[0054] Press the mixed powder into a block at 40 MPa, put it into a platinum crucible, sinter it in the air at 1100°C for 10 h, cool it down to room temperature, and grind it to obtain the first-fired powder with an average particle size of 0.5-15 μm;

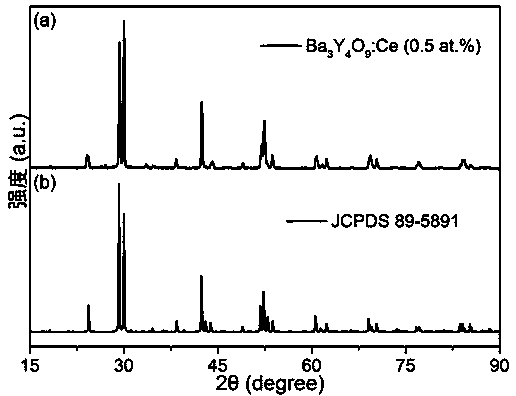

[0055] The first-fired powder was pressed into a block at 40 MPa, put into a platinum crucible, sintered at 1600 °C for 6 h in a reducing atmosphere of CO / Ar (volume ratio 5:95), cooled to room temperature, and ground to obtain the final Ba 3 Y 4 o 9 : Ce yellow phosphor, the average particle size is 0.5-15μm. The XRD pattern of the obtained phosphor powder is...

Embodiment 2

[0057] a Ba 3 Lu 4 o 9 : The preparation method of Ce (x=0.2 at. %) yellow phosphor powder is as follows:

[0058] with BaCl 2 、LuCl 3 and CeCl 3 As the initial raw material, the molar ratio of Ba:Ce:Lu is 3:0.008:3.992 for batching, each raw material is wet mixed with alcohol solution for 1 h, dried in a fume hood at room temperature, and ground to obtain an average particle size of 0.5- 5 μm mixed powder;

[0059] Press the mixed powder into a block at 40 MPa, put it into a corundum crucible, sinter in air at 1400°C for 5 h, cool down to room temperature, and grind to obtain a primary-fired powder with an average particle size of 0.5-15 μm;

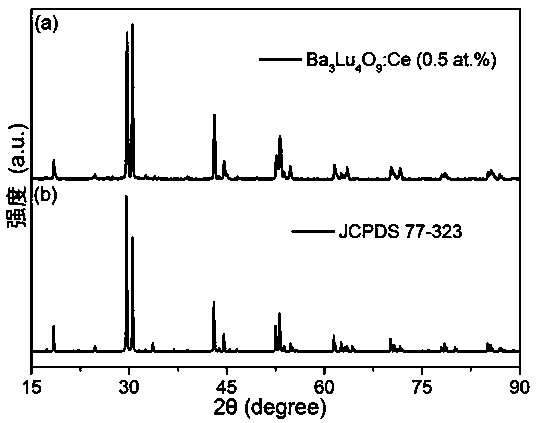

[0060] The first-fired powder was pressed into a block at 40 MPa, put into a corundum crucible, sintered at 1550 °C for 4 h in a reducing atmosphere of CO / Ar (volume ratio 5:95), cooled down to room temperature, and ground to obtain the final Ba 3 Lu 4 o 9 : Ce yellow phosphor, the average particle size is 0.5-15μm. The XRD p...

Embodiment 3

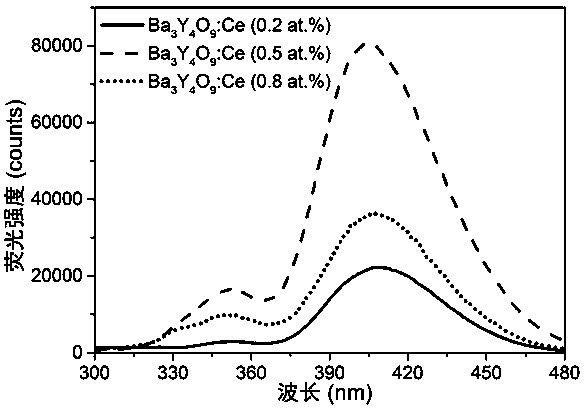

[0062] a Ba 3 Y 4 o 9 : Ce (x=0.2 at. %, 0.5 at. % and 0.8 at. %) yellow phosphor preparation method, specifically as follows:

[0063] with BaCO 3 , Y 2 o 3 and CeO 2 As the initial raw materials, the molar ratios of Ba:Ce:Y were 3:0.008:3.992, 3:0.02:3.98, 3:0.032:3.968, respectively, and the raw materials were mixed with alcohol solution for 1 h, and used at room temperature After drying in a fume hood, grind to obtain a mixed powder with an average particle size of 0.5-5 μm;

[0064] Press the mixed powder into a block at 40 MPa, put it into a corundum crucible, sinter in the air at 1350°C for 5 h, cool down to room temperature, and grind to obtain a primary-fired powder with an average particle size of 0.5-15 μm;

[0065] The first-fired powder was pressed into a block under 40 MPa, put into a corundum crucible, and heated under H 2 / N 2 (Volume ratio is 5:95) sintered at 1600 ℃ for 4 h in a reducing atmosphere, cooled to room temperature, and ground to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com