Oil and water selective self-expansion rubber plugging agent for fractured-vuggy reservoir as well as preparation method and application of rubber plugging agent

A self-expanding, rubber plugging technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of long-term stability of reservoirs, high cost, small size, etc., to achieve good economic benefits and practical application value , strong resistance to salinity, and high volume expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The embodiment of the present invention also provides a preparation method of the reservoir oil-water selective self-expanding rubber plugging agent as described in any of the above embodiments, including the following steps:

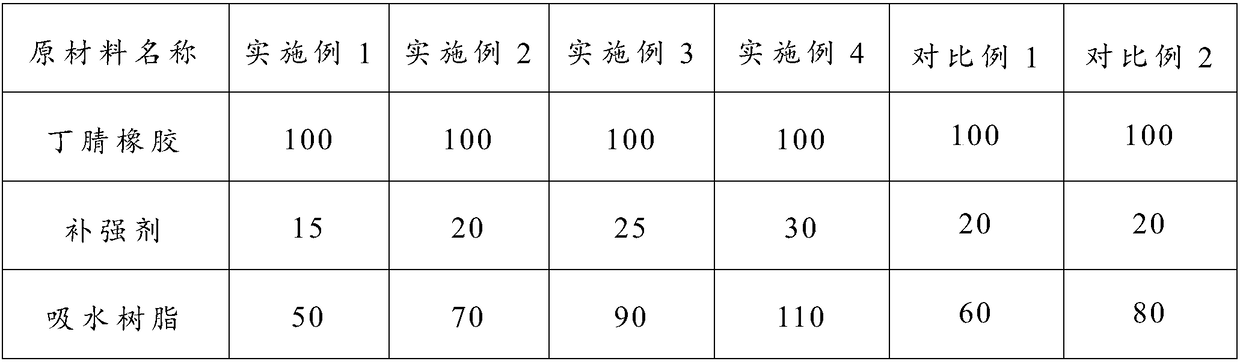

[0036] 1) 100 parts by weight of nitrile rubber is refined and masticated. After 15-30 parts of reinforcing agent is slowly added, 50-110 parts of water-absorbent resin is added, and then mixed for 5-10 minutes;

[0037] 2) Add 0.5-2 parts of softener and 2-5 parts of accelerator to the above system in sequence, and mix for 10-30 minutes;

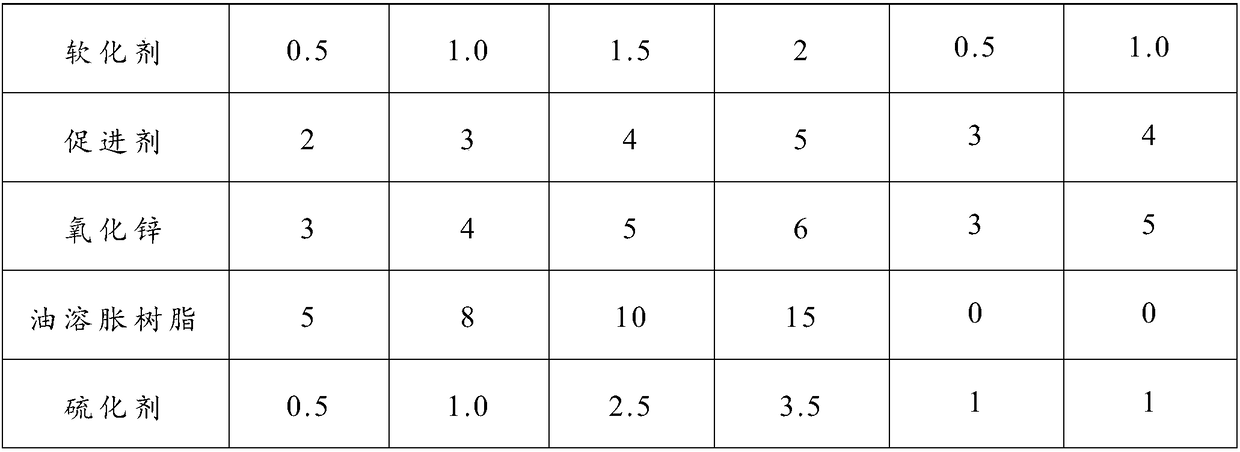

[0038] 3) Then add 3-6 parts of zinc oxide and 5-15 parts of oil swelling resin, and mix for 20-40 minutes;

[0039] 4) Add 0.5-3.5 parts of vulcanizing agent again, mix for 3-5 minutes, then uniformly slabs to obtain the mixed rubber, and cool;

[0040] 5) Extruding the cooled mixed rubber into thin rubber strips, and vulcanizing the rubber strips at 170°C to obtain vulcanized rubber strips;

[0041] 6) The obtained vul...

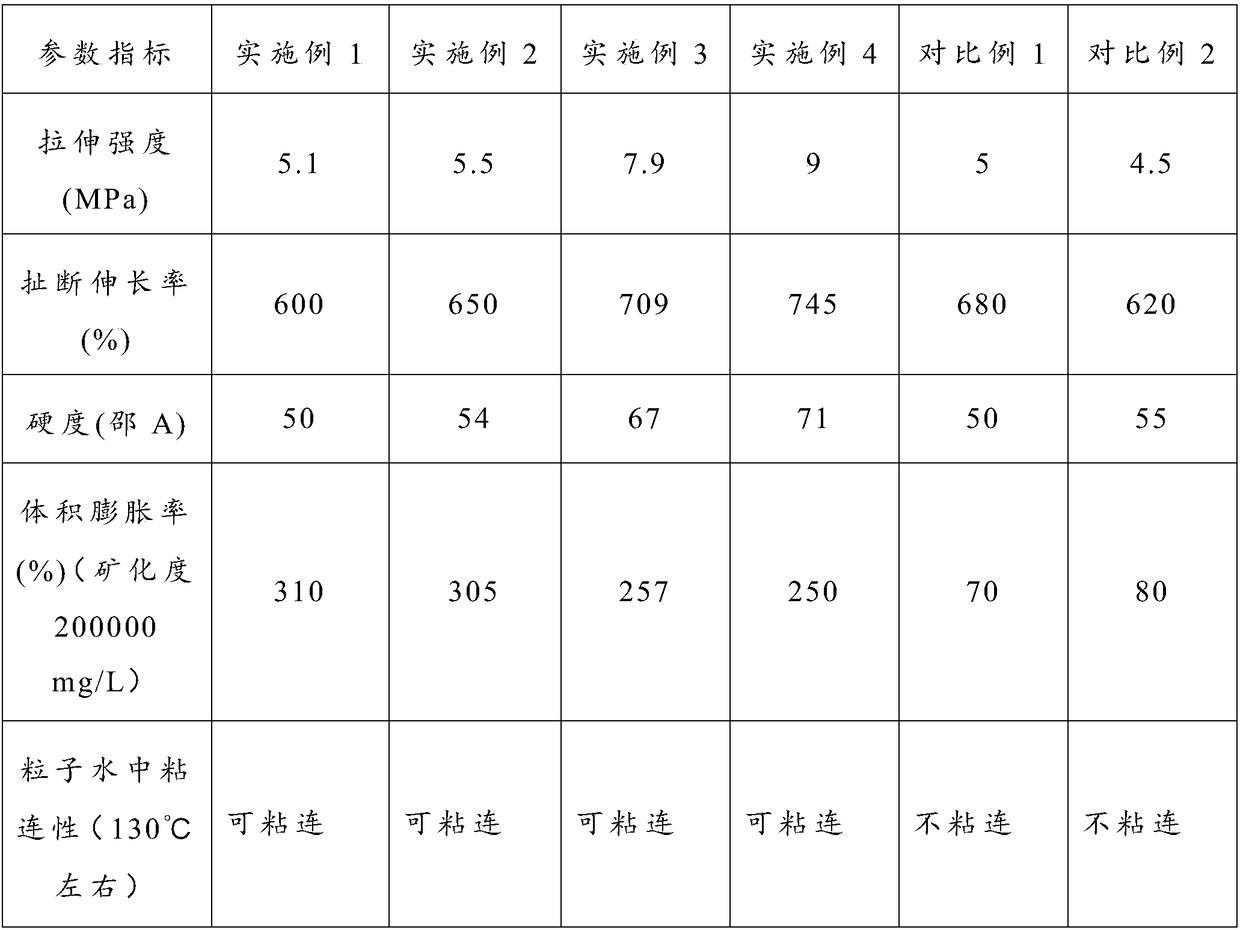

Embodiment 1

[0046] Put 100 parts of nitrile rubber into the open mill to masticate the raw rubber, weigh the parts in the formula system according to Table 1, and then add the weighed reinforcing agents, softeners, accelerators, zinc oxide, and oil one by one. The swelling resin and the vulcanizing agent are sequentially added to the open mill for mixing and mixing uniformly, and the mixed rubber is processed, and left in the cold for 24 hours. Put the mixed rubber into a mold, and vulcanize the rubber with a plate vulcanizer under the conditions of 10Mpa and 170°C to obtain a vulcanized rubber. The prepared vulcanized rubber is mechanically crushed with a crusher, and then sieved and classified by a vibrating screen to obtain rubber particles with different particle diameters.

Embodiment 2

[0048] The preparation method is the same as that of Example 1, except that the weight parts of the added components are different. See Table 1 for the specific added mass parts of each component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com