Preparation method of microvascular self-repairing coating layer

A microvascular and self-healing technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of difficult transplantation, high cost of paraffin three-dimensional microvascular, and unfavorable promotion and application of microvascular self-repairing coatings, and achieve high repair efficiency and applicability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

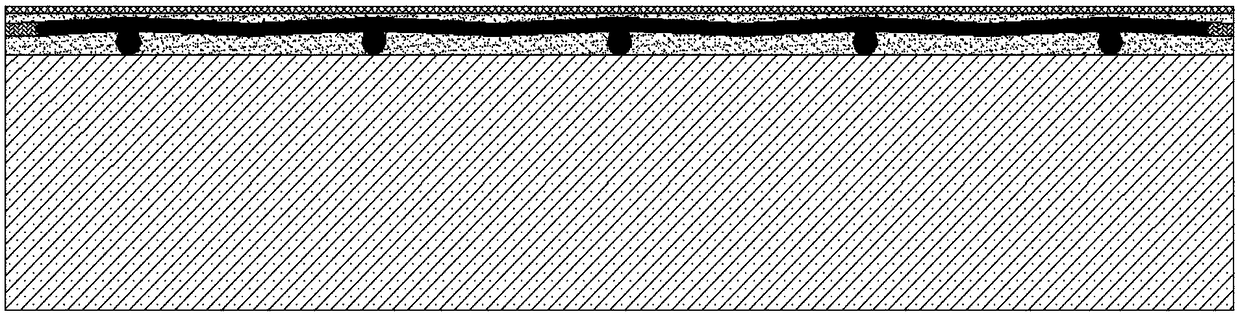

Image

Examples

Embodiment 1

[0055] A method for preparing a microvascular self-repairing coating, comprising the following steps:

[0056] Step 1, surface modification of filler: first weigh a certain amount of muscovite, ground calcium carbonate, quartz powder and nano-SiO 2 As a filler, then weigh silane coupling agent KH-560 corresponding to 1.5% of the mass of the filler, dilute the silane coupling agent KH-560 with absolute ethanol to an 8% solution by mass, and spray it evenly into the In the corresponding filler, and then dried at 60°C for later use;

[0057] Step 2, the preparation of primer: according to the quality of each component, dissolve 100 parts of epoxy resin E-44 in 80 parts of acetone solvent, add 9 parts of diethylenetriamine and 2 parts of benzyl alcohol after dissolving, and stir well Add 150 parts of modified quartz powder and keep stirring for 10-15 minutes. While stirring, add 100 parts of modified muscovite and 200 parts of modified calcium carbonate in turn, and add 50 parts ...

Embodiment 2

[0062] A method for preparing a microvascular self-repairing coating, comprising the following steps:

[0063] Step 1, surface modification of filler: first weigh a certain quality of talcum powder, light calcium carbonate instead, quartz powder and nano-SiO 2 As a filler, then weigh silane coupling agent KH-560 corresponding to the mass of 2% of the filler, dilute the silane coupling agent KH-560 with absolute ethanol into a 5% solution by mass, and spray it into the In the corresponding filler, and then dried at 60°C for later use;

[0064] Step 2, preparation of primer: according to the quality of each component, dissolve 100 parts of epoxy resin E-44 in 70 parts of acetone solvent, add 9 parts of diethylenetriamine and 2 parts of benzyl alcohol after dissolving, and stir well Add 200 parts of modified quartz powder and keep stirring for 10-15 minutes. While stirring, add 100 parts of modified muscovite and 300 parts of modified calcium carbonate in sequence, and add 10 pa...

Embodiment 3

[0069] A method for preparing a microvascular self-repairing coating, comprising the following steps:

[0070] Step 1, surface modification of fillers: first weigh a certain amount of bentonite, ground calcium carbonate, titanium dioxide and nano-SiO 2 As a filler, then weigh silane coupling agent KH-560 corresponding to 1.5% of the mass of the filler, dilute the silane coupling agent KH-560 with absolute ethanol to a 5% solution by mass, and spray it into the In the corresponding filler, and then dried at 60°C for later use;

[0071] Step 2, preparation of primer: according to the quality of each component, dissolve 100 parts of epoxy resin E-44 in 80 parts of acetone solvent, add 9 parts of diethylenetriamine and 3 parts of benzyl alcohol after dissolving, and stir well Add 200 parts of modified quartz powder and keep stirring for 10-15 minutes. While stirring, add 90 parts of modified muscovite and 200 parts of modified calcium carbonate in turn, and add 30 parts of aceton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com