Forklift efficient energy-saving system with speed regulating function

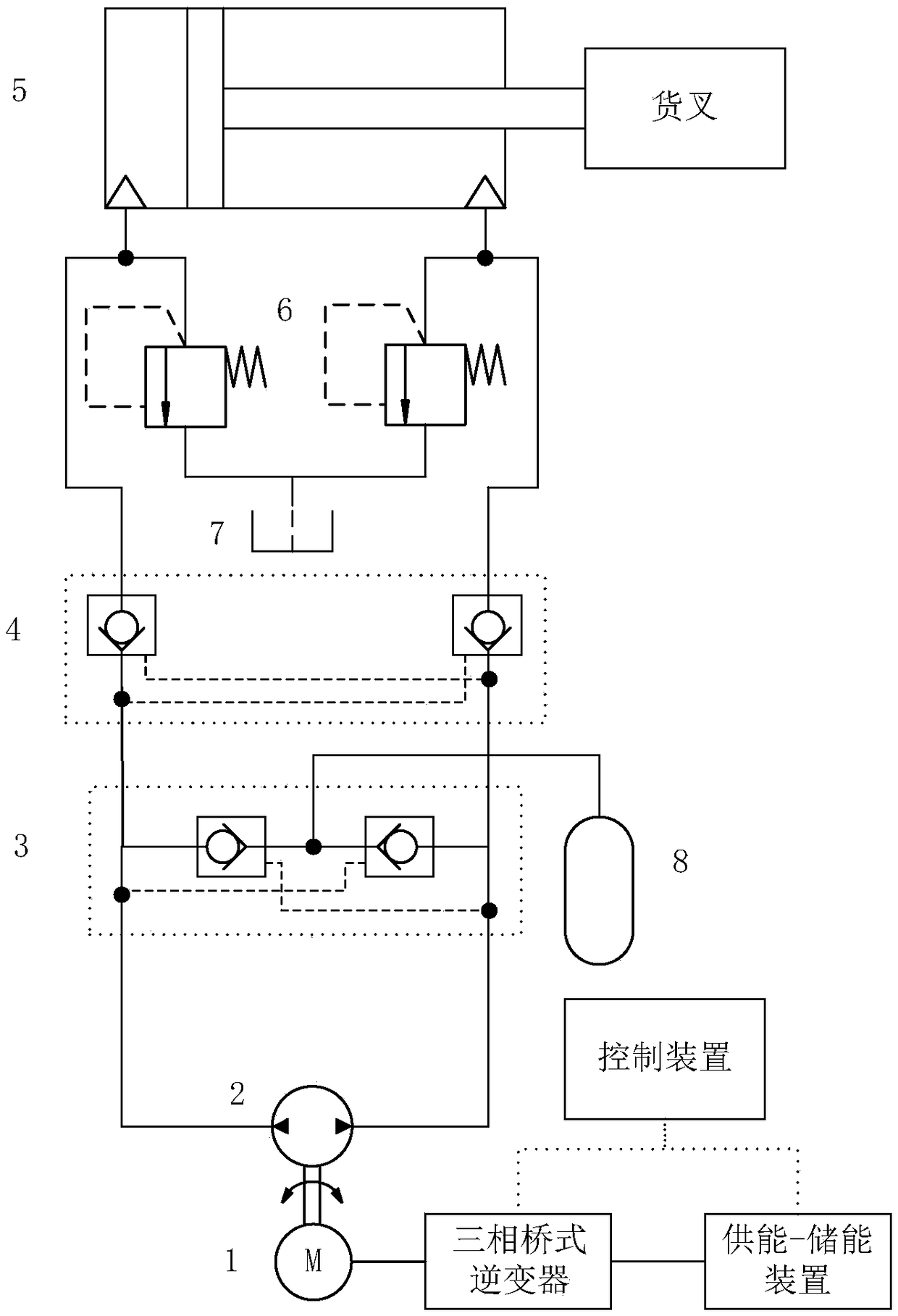

A high-efficiency, energy-saving and functional technology, applied in the components of fluid pressure actuation system, lifting device, fluid pressure actuating device, etc., can solve the problem of low control precision of manual reversing valve, large energy loss of throttling and speed regulation, and hydraulic oil circuit. Changes and other problems, to achieve the effect of prolonging the use time of a single charge and discharge, eliminating throttling loss, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, the first working state.

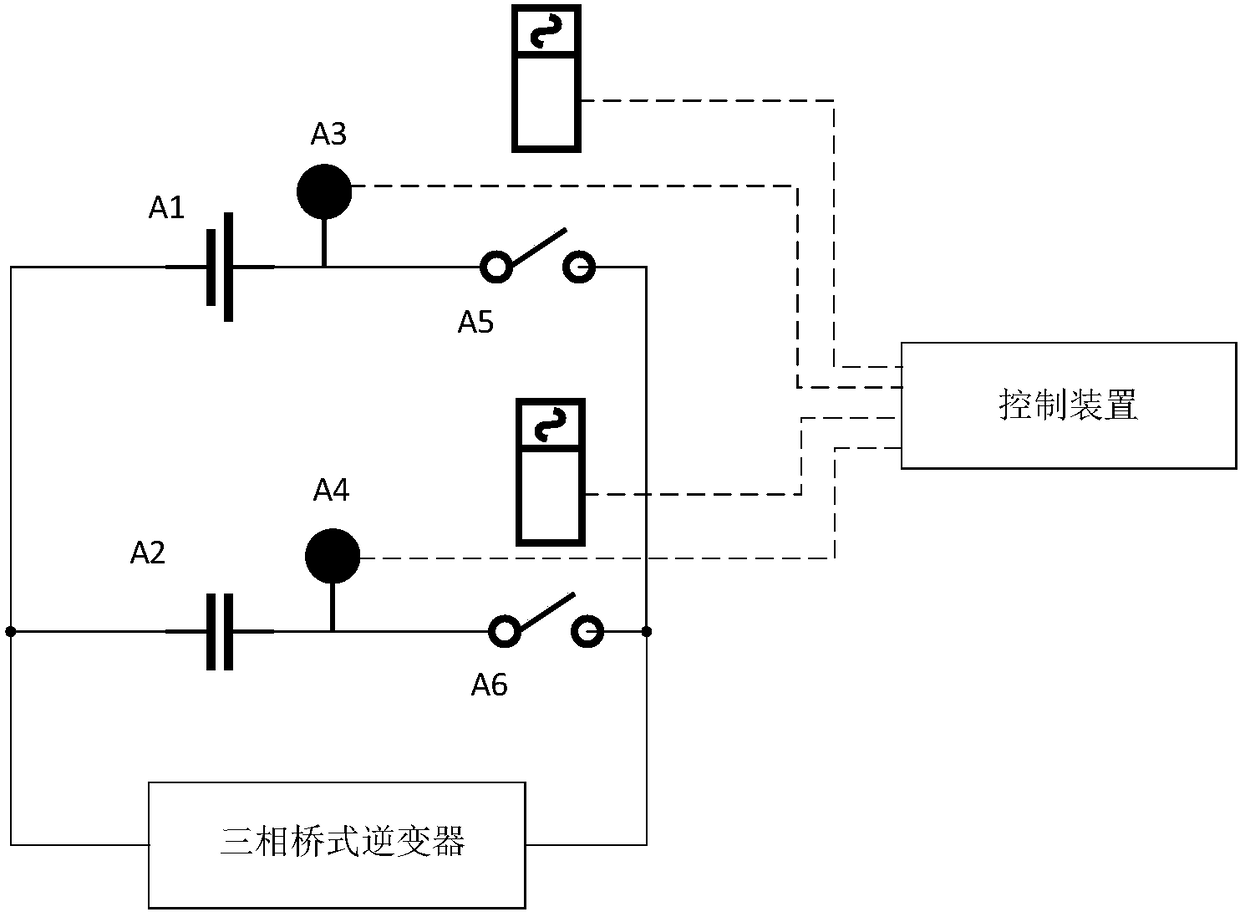

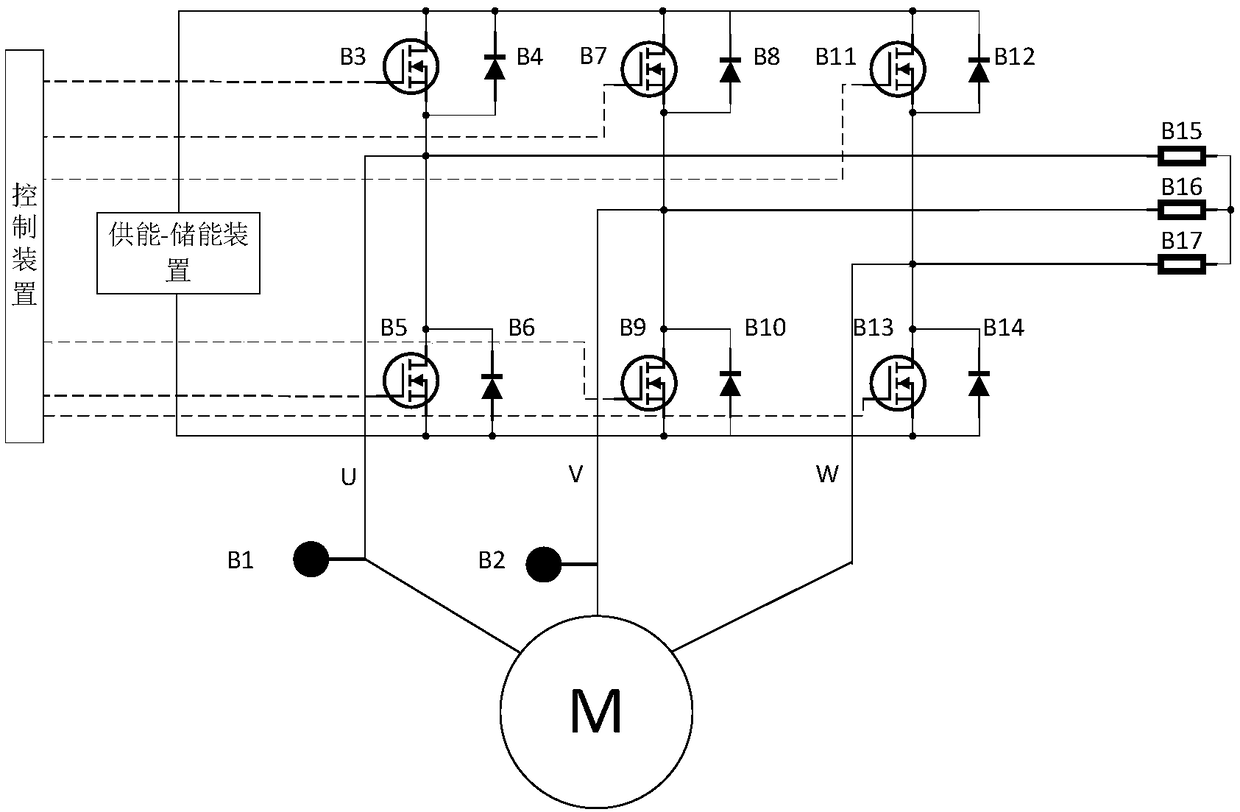

[0032] When the fork is lifted, the control device receives the lifting signal of the fork. At this time, the second voltage sensor A5 detects the voltage across the supercapacitor A2. If the voltage across the supercapacitor A2 is not lower than the rated voltage, the control device controls the first The second relay A6 is turned on, and the supercapacitor A2 provides electric energy for the moment when the forklift is lifted. The power supply time is 1 to 2 seconds or until the voltage of the supercapacitor A2 is less than 20V, and then the control device controls the second relay A6 to turn off, and the first relay A5 to turn on. The battery A1 supplies power to the forklift lifting system. At this time, the three-phase bridge inverter turns on the DC power of the supercapacitor A2 or battery A1, and the control device controls the three-phase bridge inverter MOS tubes B3, B13, B7, B5, B11, and B9 to turn on in sequence, and ...

Embodiment 2

[0033] Embodiment 2, the first working state.

[0034] When the fork is lowered, the lift cylinder 5 returns oil to the rodless cavity, the two-way hydraulic lock valve 4 is opened, and the hydraulic oil flows through the two-way hydraulic lock valve 4 into the double-acting pump-motor 2, driving the double-acting motor 2 to reverse. At this time, the double-acting motor 2 works in a pump state. The pump drives the double-acting motor 1 to reverse. At this time, the double-acting motor 1 works in the generator state, and the generator generates electricity to charge the supercapacitor A2 or the battery A1 through the three-phase bridge inverter. When the lowering speed of the fork is too fast, the current sensor and speed encoder on the generator will transmit the working speed and torque state of the generator to the control device, and the control device will compare the actual speed signal of the generator with the given speed to calculate the stator flux linkage. For the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com